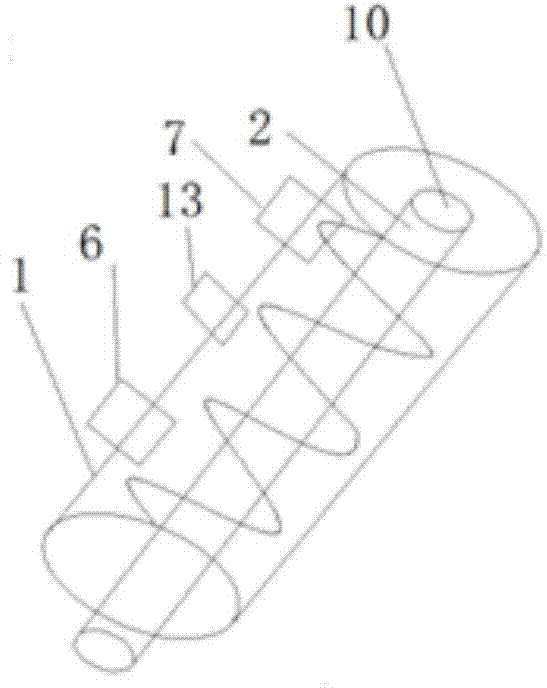

Screw rod type impregnation equipment

A screw-type, dipping technology, applied in the direction of coating, etc., can solve the problems of damage to the health of operators, short fiber dipping time, insufficient dipping, etc., to achieve the effect of convenient observation, simple equipment, and good dipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Take 0030 bundles of T700-12K carbon fiber dipped in epoxy resin with a viscosity of 3000mps as an example.

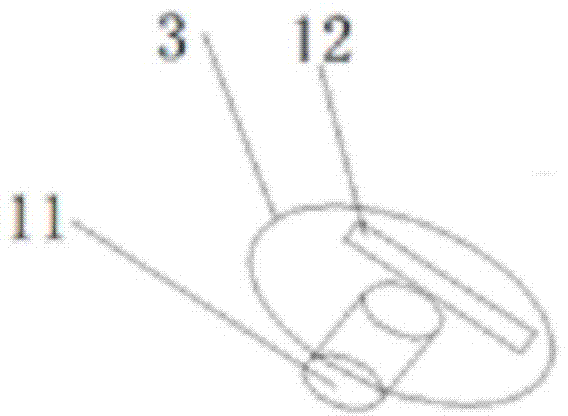

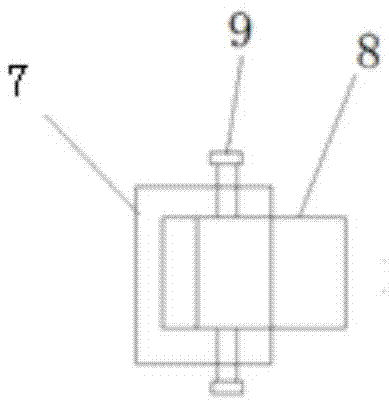

[0035] The dipping sleeve 1 and the dipping shaft 2 are made of 304 stainless steel. Insert 30 bundles of T700-12K carbon fiber through the tow inlet 7, wind them on the dipping shaft 2 according to the thread direction, and pass them out from the tow exit 6 after winding. The thread section of the dipping shaft 2 is trapezoidal, and wrap the Put the dipping shaft 2 of good carbon fiber into the dipping sleeve 1, insert one end of the dipping shaft 1 into the first cylindrical hole 10, align the second cylindrical hole 11 with the other end of the dipping shaft 2, and then cover the dipping sleeve Canister cover 3. Place the installed dipping sleeve 1 on the support 4. The insulation cover 5 is heated by a carbon fiber electric heater, and the insulation temperature is set at 40°C. Pour epoxy resin from the injection port 13. Observe the height of the glue in t

Embodiment 2

[0037] Take 50 bundles of 12K glass fibers dipped in phenolic resin with a viscosity of 7000mps as an example.

[0038] The dipping sleeve 1 and the dipping shaft 2 adopt polytetrafluoroethylene. Put 50 bundles of 12K glass fiber through the tow inlet 7, wind it on the dipping shaft 2 according to the thread direction, and pass it out from the tow outlet 6 after winding. The cross section of the thread is triangular. Put the shaft 2 into the dipping sleeve 1, insert one end of the dipping shaft 2 into the first cylindrical hole 10, align the second cylindrical hole 11 with the other end of the dipping shaft 2, and then cover the dipping sleeve cover 3. Place the installed dipping sleeve 1 on the support 4. The heat preservation cover 5 adopts the water heat preservation of setting temperature through the interior, and the heat preservation temperature is set to 60 ℃. Pour the phenolic resin from the injection port 13. Observe the height of the glue in the dipping sleeve 1 from

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap