Preparation method of polysilazane for preparation of SiCN nonoxide ceramic fibre

A technology of non-oxidized ceramics and polysilazane, applied in the field of preparation of high molecular weight polysilazane, to achieve the effect of preventing hydrolysis damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

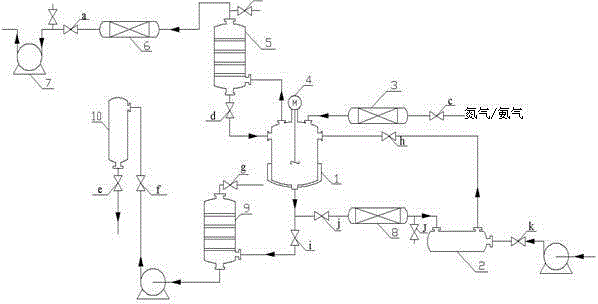

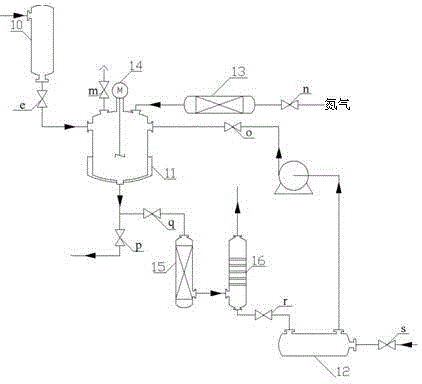

[0023] The present invention will be described in further detail below in conjunction with the embodiments shown in the accompanying drawings.

[0024] 1. Reaction process

[0025] As shown in Figure 1, the electric stirring 4 is installed on the reaction kettle 1, and is connected with the raw material tank 2 and the dryer 3, and is connected with the reflux tower 5 through the absorber 6 and the vacuum pump 7 at the same time, and the bottom valves of the filter devices 8 and 11 j is connected with the feed inlet of raw material tank 2.

[0026] First, the high-purity nitrogen enters the reactor 1 through the dryer 3, and is discharged through the devices 5, 6, and 7. At the same time, it takes away the air and water vapor in the reactor 1, and keeps it for 0.5 to 1 hour.

[0027] Second, stop the nitrogen flow, start the vacuum pump 7, open the connection valve h with 2, so that the raw materials methylhydrogendichlorosilane, methylvinyldichlorosilane and n-hexane in 2 enter

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap