Device for laser transmission welding and method for laser transmission welding

A technology of laser transmission welding and laser transparency, which is applied in the field of composite parts, can solve the problems such as the delay of disconnected parts, and achieve the effect of short welding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the invention are described below with reference to welding a multilayer membrane comprising a tie layer to a rigid filler body, without limiting the invention thereto.

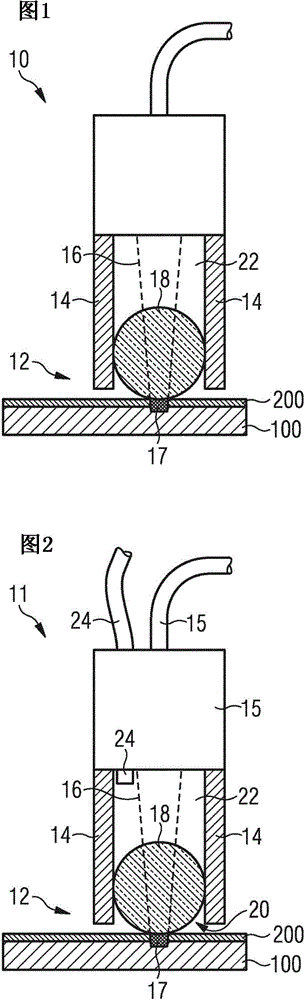

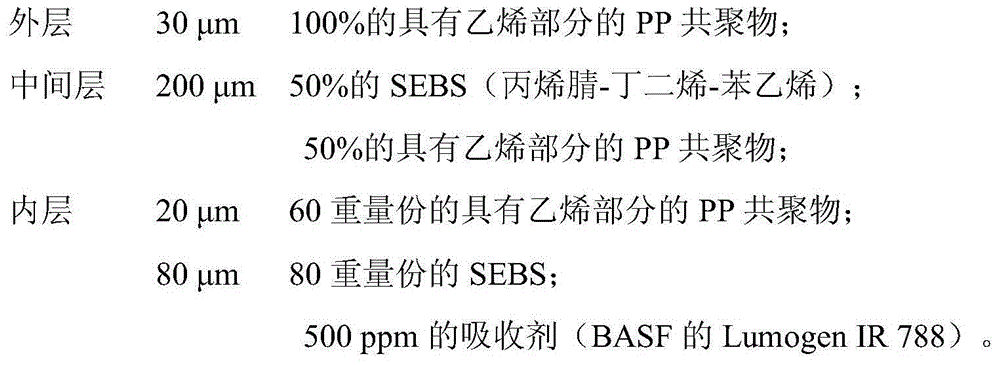

[0057] figure 1 An example of a welding setup schematically represented in , comprises a rigid plastic part 100, a multilayer film 200 arranged on the rigid plastic part 100, and a processing head 10 for laser transmission welding of the device according to the invention. In this example, the multilayer film 200 and the rigid plastic part 100 are arranged one above the other on a machined surface (not shown).

[0058] The processing head 10 has a processing side 12 which is positioned at figure 1 The center faces the multi-layer film 200 disposed above the rigid plastic part 100 . The processing side 12 is formed by the free end of a hollow cylindrical outlet shaft 14 . In this example, the outlet shaft 14 is formed from polytetrafluoroethylene (PTFE). In this outlet shaft 14 , balls 18

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap