Portal crane operation control system capable of accelerating descending

A gantry crane, operation control technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve problems such as difficult to improve work efficiency, achieve remarkable application effect, safe and reliable performance, and construction safety guarantee effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0009] The specific implementation, structure, and features provided in accordance with the present invention are described in detail below with reference to the accompanying drawings and preferred embodiments:

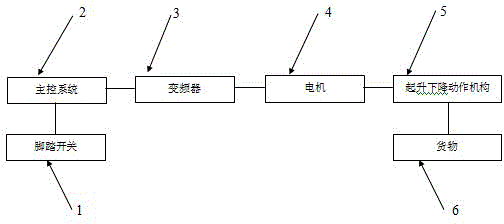

[0010] Such as figure 1 As shown, a portal crane operation control system capable of accelerating and descending includes a foot switch 1, a main control system 2, a frequency converter 3, a motor 4, and a lifting and lowering action mechanism 5; the main control system 2 Connect the inverter 3, the inverter 3 is connected to the motor 4, and the motor 4 is connected to the lifting and lowering action mechanism 5. The control system is equipped with a foot switch 1 for inputting acceleration and descent commands. The foot switch 1 is connected to the main control through a signal cable The reserved interface connection in system 2.

[0011] In application, when the gantry crane is in the lifting motion, the operator activates the relevant functions in the main control system

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap