Shoe washing machine

A technology for a shoe washing machine and an inner cylinder is applied in the field of shoe washing machines, which can solve the problems of time-consuming, laborious, and numb arms of shoes, and achieve the effects of reasonable structure, lightening of housework, and improving quality of life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

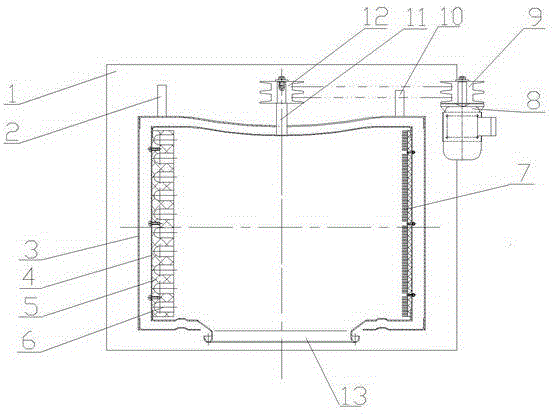

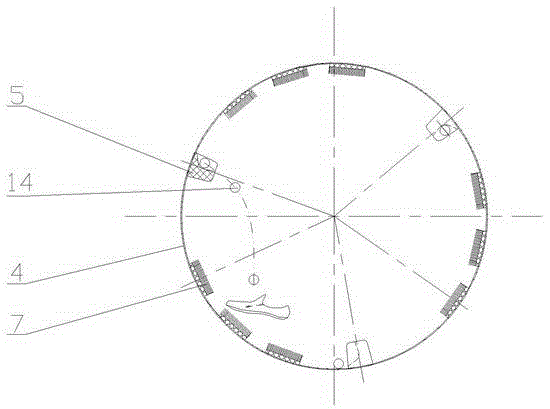

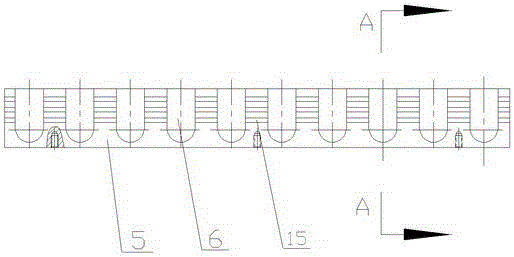

[0008] A shoe washing machine, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a horizontal outer cylinder 3 provided with inlet and outlet pipes 2, 10 is installed on the supporting device 1, and an inner cylinder 4 with a rotating shaft 11 and a supporting pipe is installed in the outer cylinder 3 through a bearing. The wall of the cylinder body is uniformly provided with water passage holes, and the pulley 12 is installed on the inner cylinder shaft 11 that extends out of the outer cylinder 3. The inner cylinder 4 of the inner cylinder 4 is uniformly spaced and arranged in a staggered arrangement on the circumferential surface of the inner cylinder wall. The brush row group and the conveying plate 5, in which the length of the brush row 7 of the brush row group is adapted to the length of the inner cylinder 4. The structure of the conveying plate 5 is that it is horizontally uniformly arranged on the long support 14 is the matching conveying channel 6, the directi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap