Solar battery bus bar bending device

A technology of solar cells and bending devices, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low welding efficiency, easy to generate welding bumps, and many welding procedures, and achieve convenient operation, less processing procedures, and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

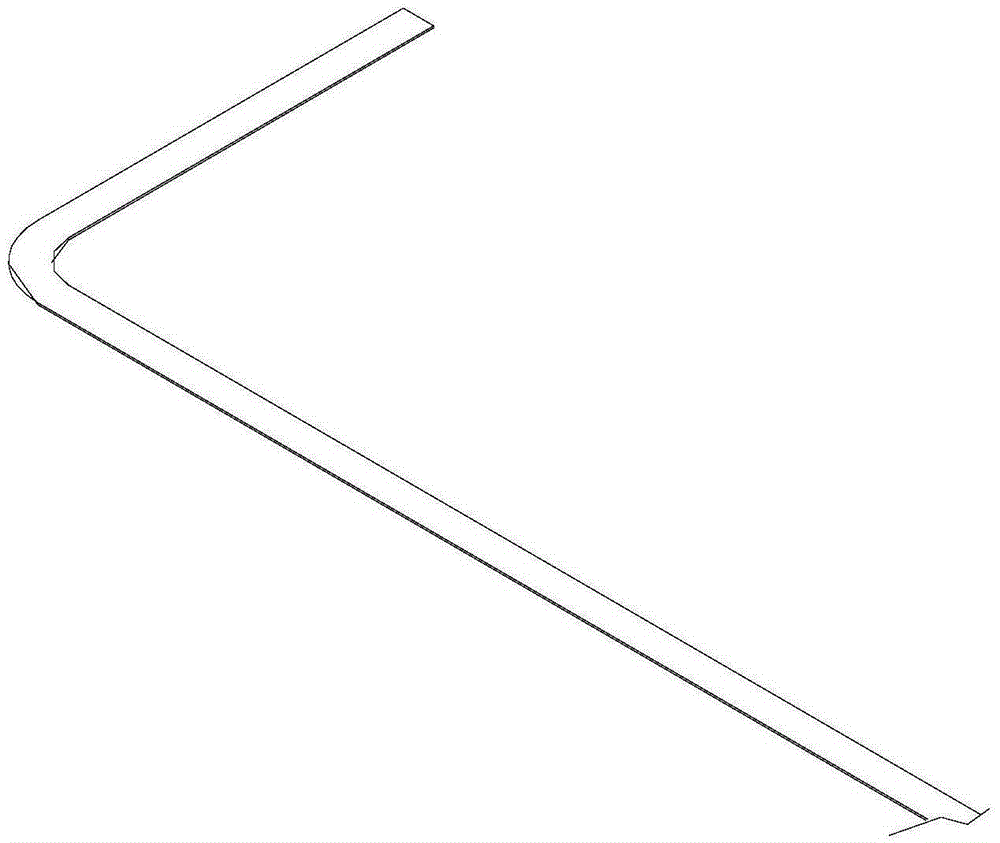

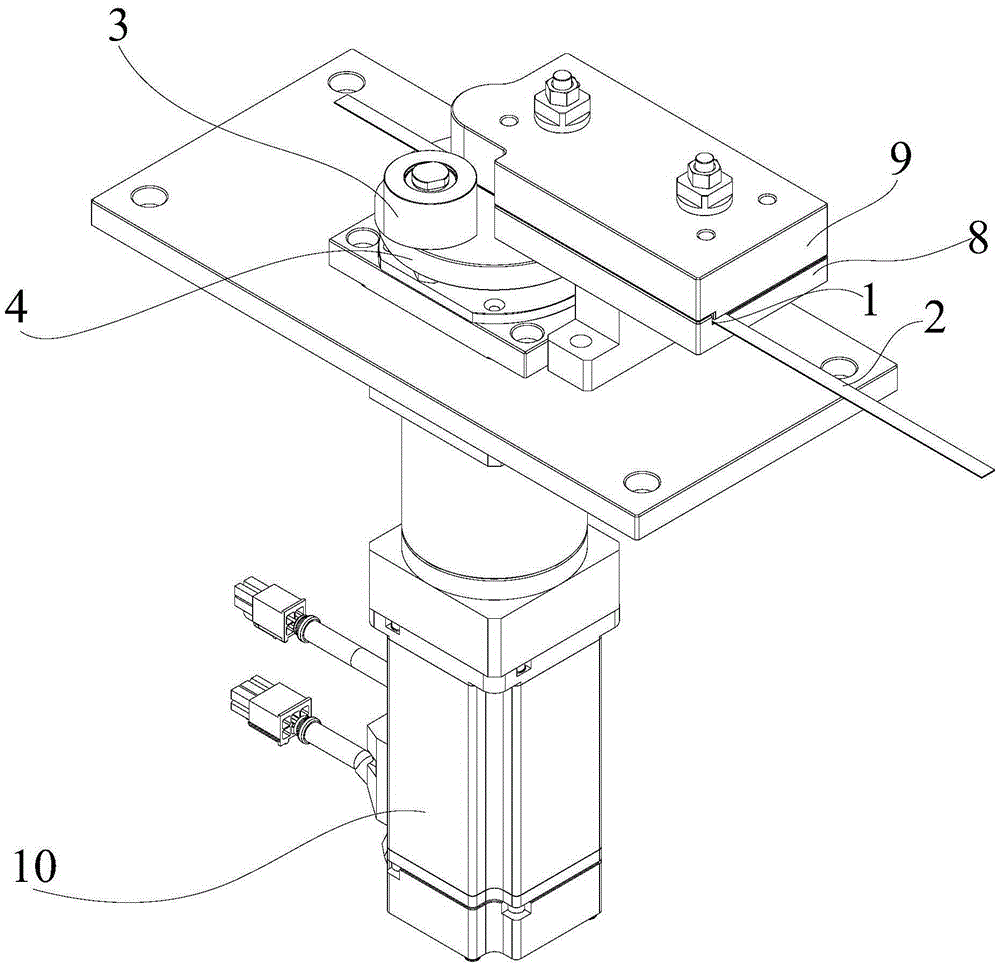

[0024] Example: solar cell bus bar bending device

[0025] See attached Figure 1~6 As shown, the solar cell bus bar bending device includes a bus bar supply groove 1 for the bus bar to pass through, and the side part corresponding to the bus bar supply groove 1 is provided with a bus current in the bus bar supply groove 1. The rolling roller 3 pressed by the bar 2 is rotatably supported on the eccentric shaft of an eccentric mechanism, and the rotating shaft of the eccentric mechanism is connected with the output shaft of a driving device 10 through transmission. The eccentric mechanism of the present embodiment is specifically an eccentric wheel mechanism, specifically, the rolling roller 3 is rotatably supported on the eccentric shaft of the eccentric wheel 4 of the eccentric wheel mechanism, and the rotating shaft of the eccentric wheel 3 is connected to the output shaft of the driving device 10 through a transmission drive. The device 10 may be a hydraulic motor or an elect

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap