Building material curling equipment

A building material roll and equipment technology, applied in the field of building material hemming equipment, can solve the problems of reducing the composite fastness of the upper profile and the lower profile, time-consuming and laborious adjustment, low work efficiency, etc., and achieves simple structure, stable operating environment and low processing cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

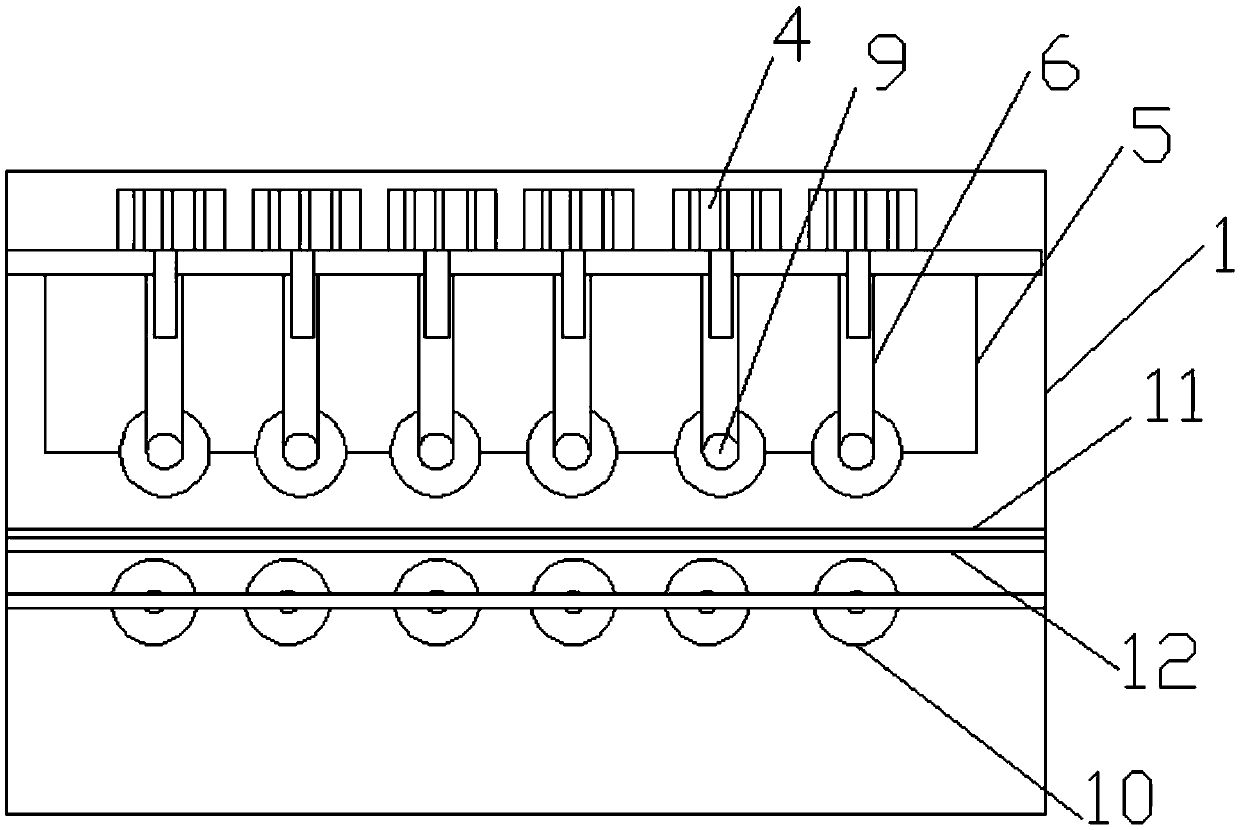

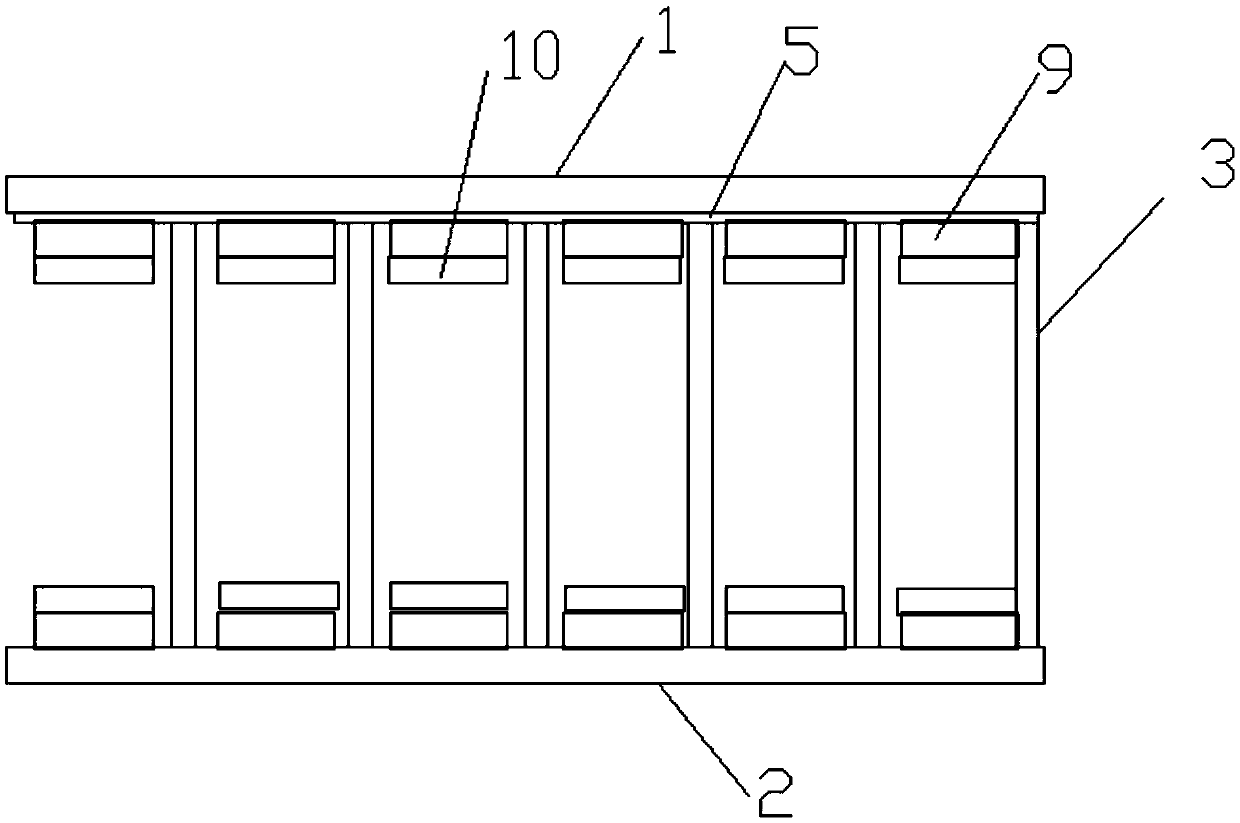

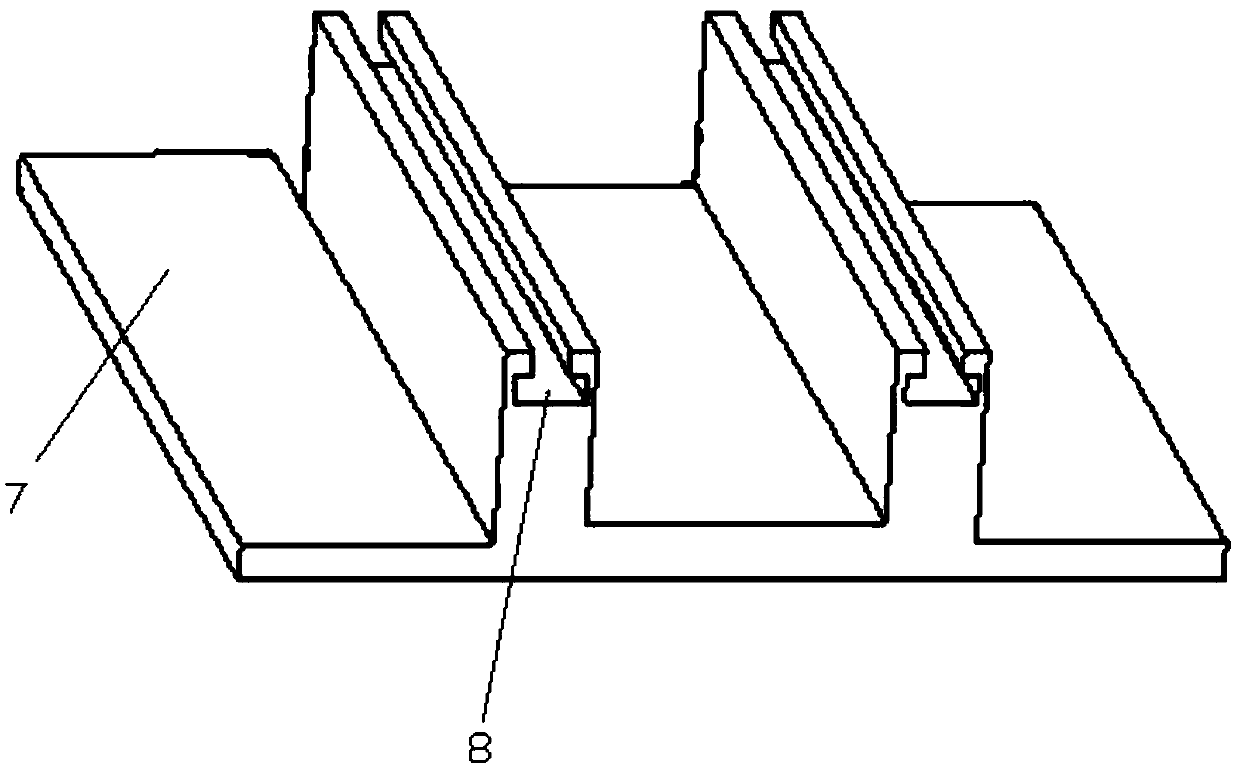

[0020] Such as Figure 1-3 As shown, the technical solution of the present invention is: a kind of building material crimping equipment, comprising front and rear support plates, a plurality of transmission rollers 3 are arranged between the front support plate 1 and the rear support plate 2, on the transmission rollers 3, An extruding mechanism and a support mechanism are respectively arranged below, and the extruding mechanism includes a cylinder 4, a guide 5 and a moving rod 6, and a guide 5 is respectively symmetrically arranged on the front and rear support plates, and the guide 5 Including a guide plate 7 and a guide groove 8, the guide plate 7 is fixed on the support plate, a plurality of guide grooves 8 are arranged on the guide plate 7, and each guide groove 8 is provided with a moving rod 6 matched with it, The upper end of the moving rod 6 is connected with the piston rod of the cylinder 4, and the lower end of the moving rod 6 is connected with the extrusion wheel 9,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap