Manufacturing method of pearl powder peel-off face mask

A production method and pearl powder technology, applied in the field of beauty and beauty, can solve the problems of inconvenient cleaning, easy flow to neck hair, discomfort, etc., and achieve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

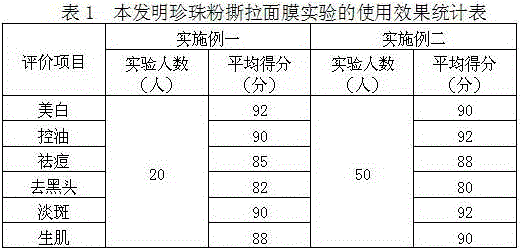

Embodiment 1

[0015] This example is to make a ready-to-use facial mask for 1 person. The raw materials used in this pearl powder peeling mask are as follows: 15g pearl powder, 5g polyvinyl alcohol powder, 5g urea sac, 1g glycerin, 0.5g camellia oil, 0.3g dimethyl silicone oil, 0.3g polysorbate, 10g distilled water, 35g milk.

[0016] The production method is as follows:

[0017] A. Put the vinyl alcohol powder into a reaction vessel, add 10 g of distilled water at 70-80°C, and stir until the polyvinyl alcohol powder is fully dissolved to obtain a polyvinyl alcohol solution;

[0018] B. In a water bath at 70~80℃, add pearl powder, urea sac, glycerin, camellia oil, simethicone, polysorbate and milk to the polyvinyl alcohol solution obtained in step A, and stir for 5-10min. Mix thoroughly to obtain a mixture;

[0019] C. Place the mixed solution obtained in step B in a room temperature environment for 3 to 5 minutes, and cool to room temperature to obtain a gelatinous pearl powder tear-off mask that ca

Embodiment 2

[0022] This example is an industrially produced facial mask that needs to be packaged for 2000 people. The raw materials used for this pearl powder peeling mask are as follows: pearl powder 40kg, polyvinyl alcohol powder 14kg, urea sac 15kg, glycerin 5kg, camellia oil 1g, 0.8 kg of dimethyl silicone oil, 2 kg of polysorbate, 56 kg of distilled water, and 30 kg of milk.

[0023] The production method is as follows:

[0024] A. Put the vinyl alcohol powder into the reaction vessel, add 10 kg of distilled water at 70-80°C, and stir until the polyvinyl alcohol powder is fully dissolved to obtain a polyvinyl alcohol solution;

[0025] B. Add pearl powder, urea sac, glycerin, camellia oil, simethicone, polysorbate, milk and the remaining distilled water to the polyvinyl alcohol solution obtained in step A in a water bath at 70~80℃, and stir 5~10min, mix thoroughly to obtain a mixed solution;

[0026] C. Place the mixed solution obtained in step B in a room temperature environment for 3 to 5 m

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap