Environment-friendly high-effective degreaser and preparation method of same

A degreasing agent, high-efficiency technology, applied in the field of environmental protection and high-efficiency degreasing agent and its preparation, can solve the problems of lack of market competitiveness, poor anti-rust performance, high production cost, etc., achieve good anti-rust effect, low environmental pollution, and low production cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

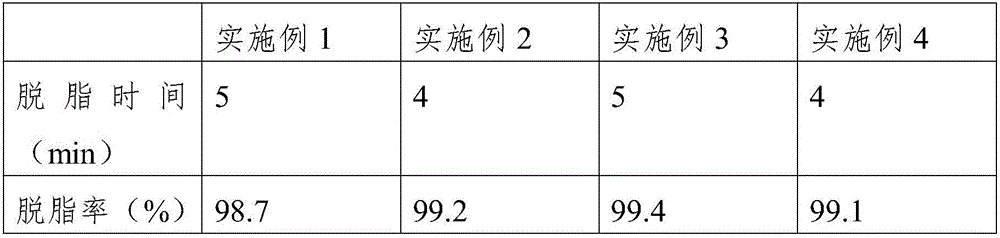

Examples

Embodiment 1

[0051] A kind of environment-friendly efficient degreasing agent, comprises A, B two kinds of components, by weight, described A, the prescription of B two kinds of components comprises following raw material:

[0052] A component:

[0053] Alpha-olefin sulfonate: 3.6g / L

[0054] Aromatic amine oxide cationic surfactant: 4.2g / L

[0055] Lauric Alkyl Alcoholamide: 4.2g / L

[0056] Carboxymethyl cellulose: 8.6g / L

[0057] 500-1000 mesh activated sludge: 12.0g / L

[0058] Citric acid: 1.5g / L

[0059] Triethylenetetramine: 3.0g / L

[0060] the rest is water;

[0061] B component:

[0062] Glucose: 4.8g / L

[0063] Lauryl sulfate tryptone: 1.2g / L

[0064] Agar: 2.5g / L

[0065] Calcium carbonate: 0.5g / L

[0066] Magnesium sulfate: 1.0g / L

[0067] Ferrous sulfate: 0.8g / L

[0068] Sodium chloride: 0.2g / L

[0069] Potato juice: 11.0g / L

[0070] Polymyxa: 10 billion units / L

[0071] The rest is water.

[0072] Its preparation method comprises th

Embodiment 2

[0077] A kind of environment-friendly efficient degreasing agent, comprises A, B two kinds of components, by weight, described A, the prescription of B two kinds of components comprises following raw material:

[0078] A component:

[0079] Alpha-olefin sulfonate: 2.0g / L

[0080] Aromatic amine oxide cationic surfactant: 6.0g / L

[0081] Lauric Alkyl Alcoholamide: 1.2g / L

[0082] Carboxymethyl cellulose: 12.0g / L

[0083] 500-1000 mesh activated sludge: 6.0g / L

[0084] Citric acid: 3.5g / L

[0085] Triethylenetetramine: 1.0g / L

[0086] the rest is water;

[0087] B component:

[0088]Glucose: 3.0g / L

[0089] Lauryl sulfate tryptone: 2.4g / L

[0090] Agar: 1.0g / L

[0091] Calcium carbonate: 1.5g / L

[0092] Magnesium sulfate: 2.0g / L

[0093] Ferrous sulfate: 1g / L

[0094] Sodium chloride: 0.5g / L

[0095] Potato juice: 5.0g / L

[0096] Polymyxa: 10 billion units / L

[0097] The rest is water.

[0098] Its preparation method is with embodime

Embodiment 3

[0100] A kind of environment-friendly efficient degreasing agent, comprises A, B two kinds of components, by weight, described A, the prescription of B two kinds of components comprises following raw material:

[0101] A component:

[0102] Alpha-olefin sulfonate: 2.8g / L

[0103] Aromatic amine oxide cationic surfactant: 5.4g / L

[0104] Lauric acid alkylolamide: 2.8g / L

[0105] Carboxymethyl cellulose: 10.5g / L

[0106] 500-1000 mesh activated sludge: 8.0g / L

[0107] Citric acid: 3.0g / L

[0108] Triethylenetetramine: 1.5g / L

[0109] the rest is water;

[0110] B component:

[0111] Glucose: 3.4g / L

[0112] Lauryl sulfate tryptone: 2.0g / L

[0113] Agar: 1.5g / L

[0114] Calcium carbonate: 1.0g / L

[0115] Magnesium sulfate: 1.5g / L

[0116] Ferrous sulfate: 1.2g / L

[0117] Sodium chloride: 0.3g / L

[0118] Potato juice: 5.0g / L

[0119] Polymyxa: 10 billion units / L

[0120] The rest is water.

[0121] Its preparation method is with embodi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap