High-precision treadmill printing machine driven by double servo motors

A technology of dual servo motors and servo motors, applied in printing, printing machines, rotary printing machines, etc., can solve the problem of affecting the position accuracy of the treadmill flat screen printing machine, increasing the mechanical gap between the positioning rod and the positioning groove, and affecting the printing accuracy, etc. problems, to achieve the effect of low noise, reasonable structure and improved printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Now in conjunction with accompanying drawing, the present invention will be further described:

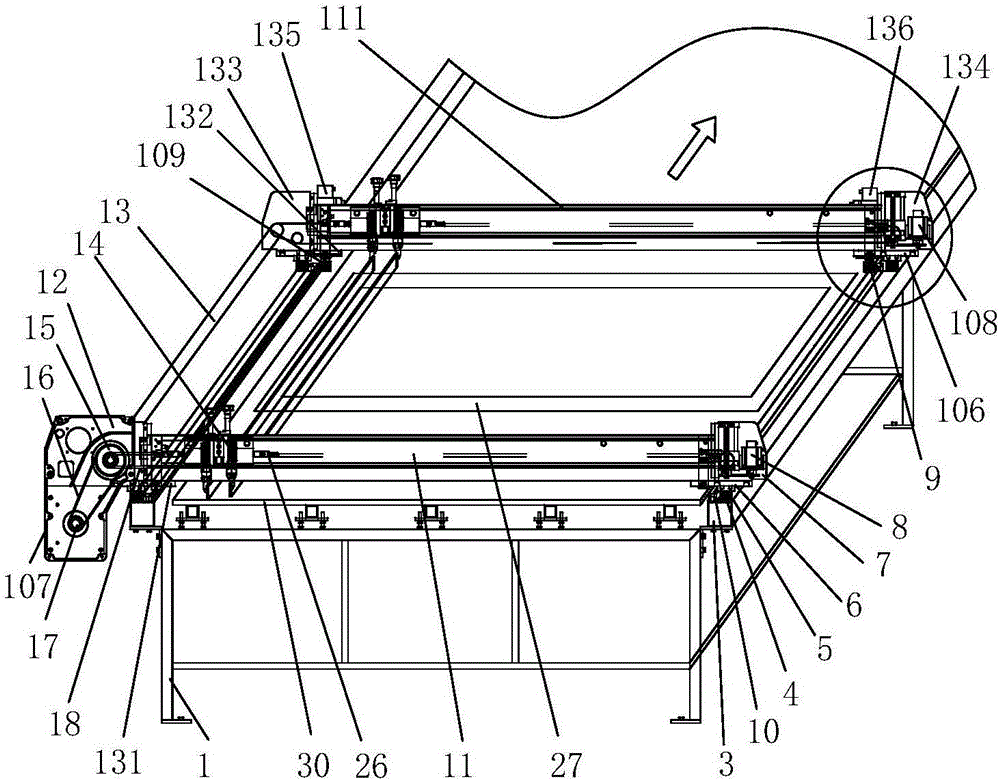

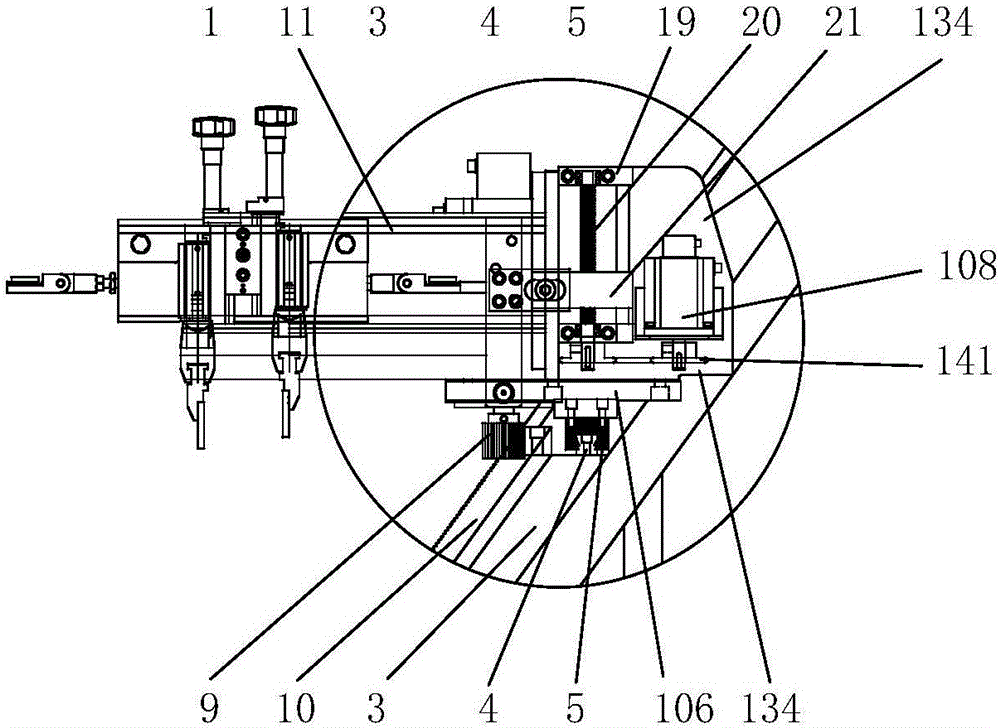

[0051] As shown in the figure, a high-precision treadmill printing machine driven by double servo motors, including:

[0052] Rack 1;

[0053] Printing platform 30, fixed on the frame 1, for placing gray cloth;

[0054] The net frame 27 is placed and closely attached to the top of the gray cloth, and is fixed on the frame 1;

[0055] It is characterized in that it also includes:

[0056] Two guide rail brackets 3 are symmetrically fixed on both sides of the rack 1;

[0057] Two racks 10 are symmetrically fixed on the rail bracket 3;

[0058] Two slide rails 4 are symmetrically fixed on the guide rail bracket 3 and parallel to the rack 10;

[0059] The first scraping track beam 11, the bottom of the left end is fixed on the first left scraper base 131;

[0060] The second scraping track beam 111, the bottom of the left end is fixed on the second left scraper base 132, the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap