Manufacturing method of mobile phone shell

The technology of a mobile phone shell and manufacturing method, which is applied in the field of mobile phone shell manufacturing, can solve problems such as cracks, pores, and poor compactness, and achieve the effects of simple processing, time and cost saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example 1

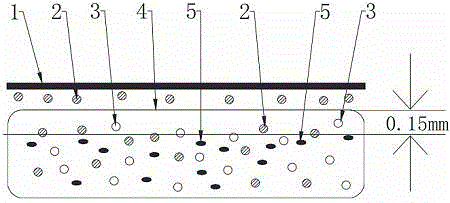

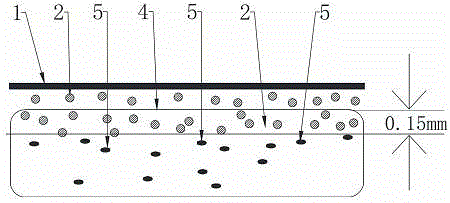

[0034] The present invention adopts a technical solution as a method for manufacturing a mobile phone shell. The manufacturing method is to put a solid metal part of the shell of the mobile phone into a die-casting mold, and then inject a die-casting material with a lower melting point than the solid metal part of the shell into the die-casting mold Die-casting, the inner surface structure of the mobile phone shell is made from the die-casting material, and the solid metal part of the shell is used as the outer surface of the mobile phone shell to make the mobile phone shell, such image 3 Shown.

[0035] In this embodiment, the solid metal part of the housing is made of pure aluminum, the die-casting material is aluminum alloy, and the aluminum alloy is aluminum-magnesium alloy or aluminum-manganese alloy. It adopts die-casting of solid metal parts of the shell made of aluminum alloy and aluminum. During die-casting, the aluminum in the die-casting material can m

Example Embodiment

[0041] Example 2

[0042] On the basis of Embodiment 1, in the method for manufacturing a mobile phone casing of this embodiment, the solid metal part of the casing is stainless steel of non-aluminum metal material, and the die-casting material is aluminum alloy. The thickness of the solid metal part of the shell is 0.55mm.

[0043] The combination of aluminum alloy and stainless steel shell metal solid parts is weak in the die casting process. It is necessary to process the inner surface of the shell metal solid parts with undercuts and burrs for combining with the die casting material to improve the die casting material and the shell metal solid parts Bond strength. Undercuts and burrs are produced by computer numerical control machine tools or stamping.

[0044] After die-casting, the outer surface of the solid metal part of the shell is polished off by a computer numerical control machine tool to remove the silicon in the release agent adhering to the outer surface of the solid

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap