Latch hook component, locking mechanism and automobile

A locking mechanism and locking hook technology, applied in the locking hook assembly, locking mechanism and automobile fields, can solve the problem of easy breakage of the back door strut due to weight, and achieve the advantages of reducing roaring noise, prolonging service life and improving performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

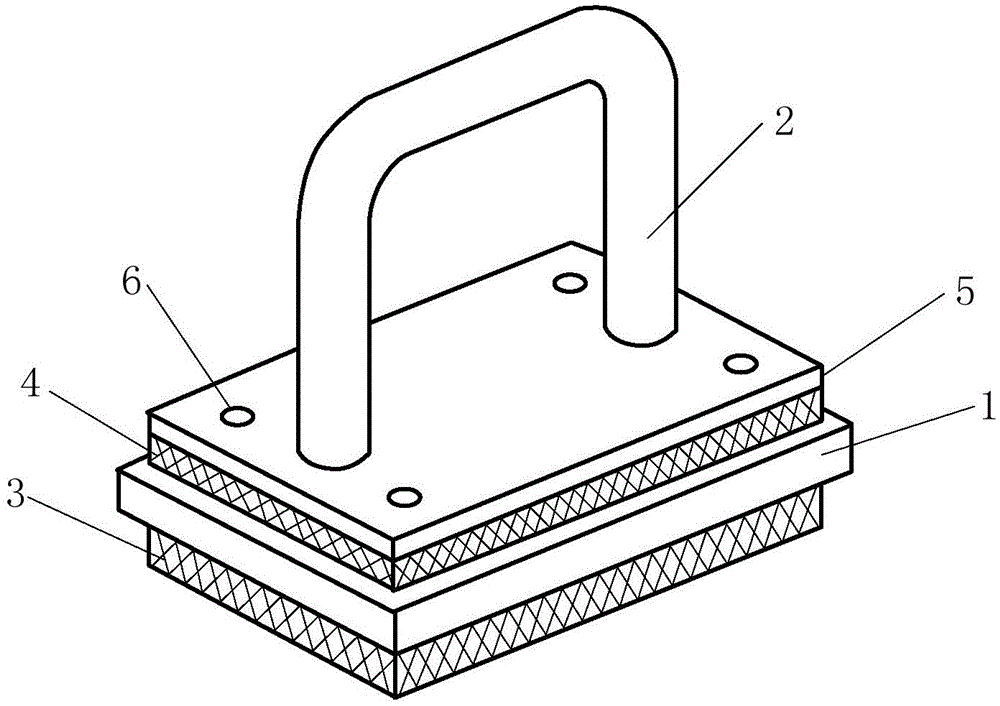

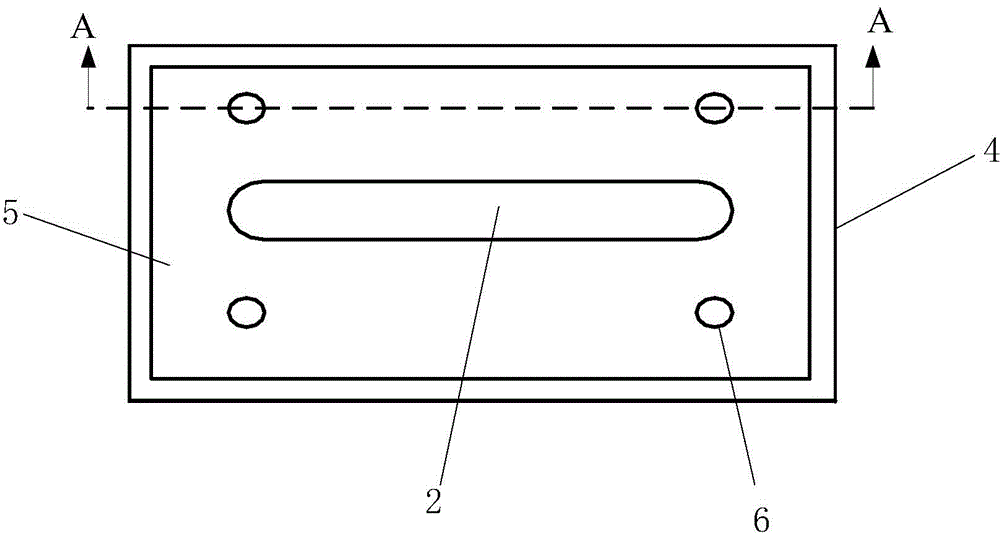

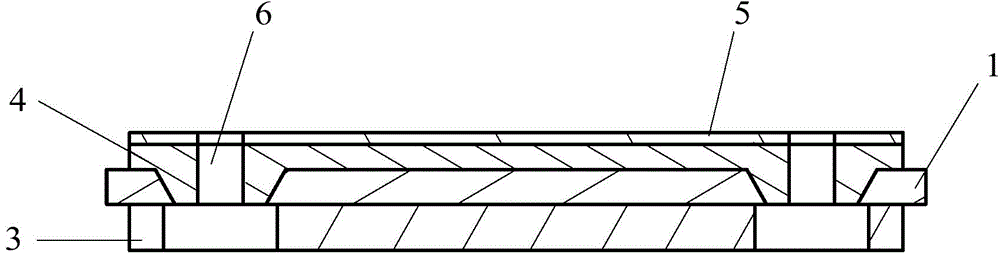

[0039] see figure 1 , the embodiment of the present invention provides a lock hook assembly, including: a base 1, a lock hook 2 and an elastic member, wherein the base 1 is fixedly connected with the vehicle body, the lock hook 2 is arranged on the base 1, and the lock hook 2 is connected to the back The door lock on the door is relatively arranged, and the elastic member is arranged on the side of the base 1 facing the door lock. figure 1 Among them, the elastic member is arranged above the base 1 . During the running of the car, the vibration of the chassis of the car and the vibration of the engine caused by the bumps of the road surface will be transmitted to the lock hook assembly through the vehicle body, and then transmitted to the back door through the lock hook assembly. Since the lock hook assembly is provided with an elastic piece, the elastic piece will absorb part of the vibration transmitted from the vehicle body, so that the vibration transmitted to the back door

Embodiment 2

[0047] Embodiment 2 of the present invention provides a locking mechanism, including: a door lock, and a lock hook assembly matched with the door lock as provided in Embodiment 1. Since the lock hook assembly is provided with an elastic piece, the elastic piece will absorb part of the vibration transmitted from the vehicle body, so that the vibration transmitted to the back door via the lock hook assembly is reduced, so that the vibration in the car due to the vibration of the back door can be reduced. Rumble is reduced, so there is no need for a shock absorber on the tailgate. Since the lock hook assembly is installed on the vehicle body, it will not increase the weight of the back door, so compared with the shock absorber installed on the back door in the prior art, the lock hook assembly provided by the embodiment of the present invention can reduce the weight of the back door The roar in the car caused by the door vibration reduces the weight of the back door at the same time

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap