Deoxidizing device of heat supply system

A heat supply system and deaerator technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high deoxygenation cost, oxygen corrosion of steel equipment, operation Complicated problems, to achieve good oxygen removal effect, strong applicability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

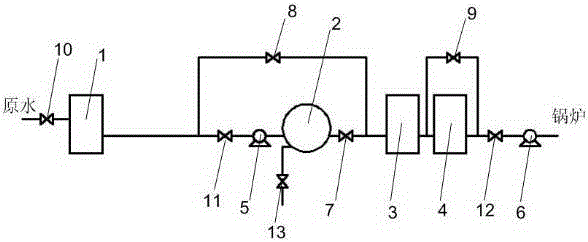

[0025] Such as figure 1 As shown, a deaeration device in a heating system includes a main valve 10 that controls the delivery of raw water to the boiler, and the pipeline between the raw water and the boiler is sequentially provided with a water softener 1, a No. 1 transfer pump 5, and a deaerator 2 , Deoxygenation water tank 3, iron and manganese removal filter 4, No. II transfer pump 6, No. I transfer pump 5, deaerator 2 The series pipeline formed by deaerator 2 is connected in parallel with deaeration valve 8, and the two ends of iron and manganese removal filter 4 are connected with The iron removal valves 9 are connected in parallel, the water inlets of No. I transfer pump 5 and No. II transfer pump 6 are respectively provided with No. I pump valve 11 and No. II pump valve 12, and the water outlet of deaerator 2 is provided with a check The valve 7 and the blo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap