Anti-explosion LNG thermal insulation tank

A technology for thermal insulation tanks and cold tanks, which is applied in the method of container discharge, container filling method, gas/liquid distribution and storage, etc., can solve the problems of storage tank explosion, adverse personal and property safety, easy to cause explosion, etc., to avoid injury. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

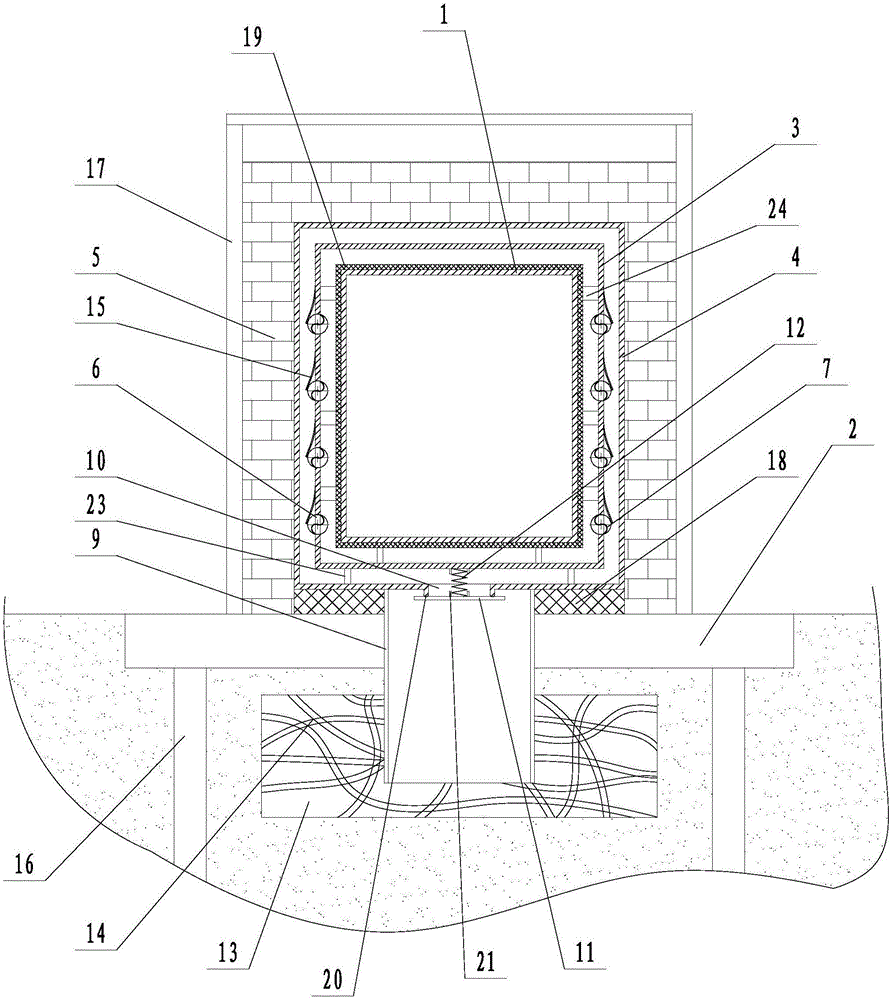

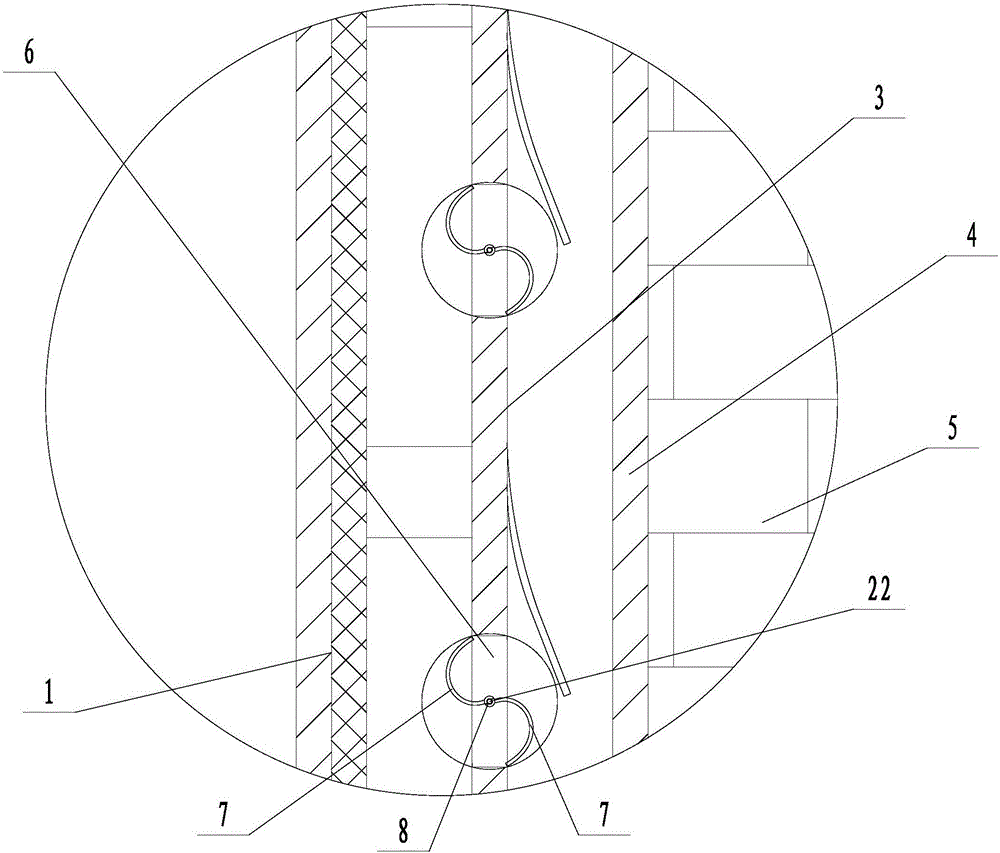

[0017] Embodiment: a kind of explosion-proof LNG insulation tank (see attached figure 1 , attached figure 2 ), including a cold storage tank 1, an installation platform 2, a buffer cylinder 3 and a closed cylinder 4 are arranged on the outside of the cold storage tank in turn, and a protective wall 5 is arranged outside the closed cylinder, and the protective wall is arranged on the installation platform. The cold storage tank body and the There is a gap between the buffer cylinders and between the buffer cylinder and the closed cylinder. The lower end of the cold insulation tank is connected to the bottom of the buffer cylinder through the connecting column 23, and the lower end of the buffer cylinder is connected to the bottom of the closed cylinder through the connecting column. A plurality of connection blocks 24 are connected between the outer wall of the cold storage tank and the inner wall of the buffer cylinder. A number of air holes 6 are arranged on the side wall of t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap