High-temperature cabinet

A technology for high-temperature boxes and boxes, which is applied to heating or cooling equipment, laboratory appliances, chemical instruments and methods, etc., can solve the problems of large power consumption and low heat energy utilization rate of high-temperature boxes, and achieve high heat energy utilization rate, The effect of high heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Now do further detailed explanation in conjunction with accompanying drawing.

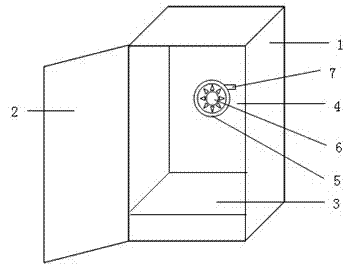

[0010] Such as figure 1 As shown, a high-temperature box includes a box body 1, a box door 2, a box cavity 3 and an air circulation heating device 4, and the air circulation heating device includes a motor 5, a fan 6, and an electric heating element 7, and the air circulation heating The device 4 is electrically connected to the control power supply. The electric heating element 7 is a circular plate metal substrate, and the side of the metal substrate corresponding to the fan 6 is covered with an electrothermal film, and the electrothermal film includes a stainless steel thick film layer.

[0011] The above descriptions are only illustrative specific implementations of the present invention, and are not intended to limit the scope of the present invention. Any equivalent changes and modifications made by those skilled in the art without departing from the concept and principle of the present

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap