Sandpaper polishing machine for ceramic tile

A technology for ceramic tiles and grinding machines, which is applied to belt grinders, grinding machines, grinding/polishing equipment, etc., which can solve the problems of easy pricking, rough surface feel, and sand hanging, etc., to achieve improved versatility, fine and natural texture, Produce stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

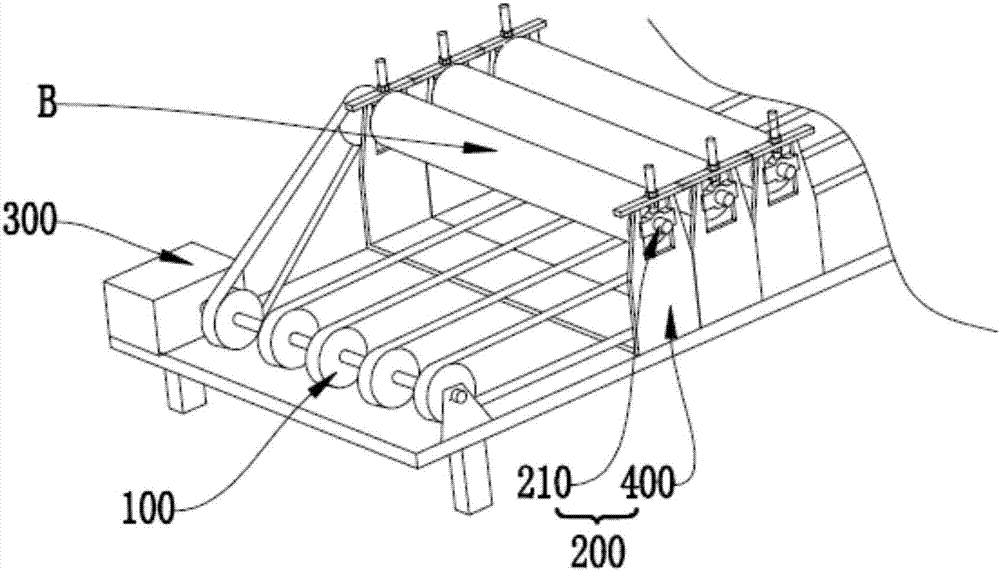

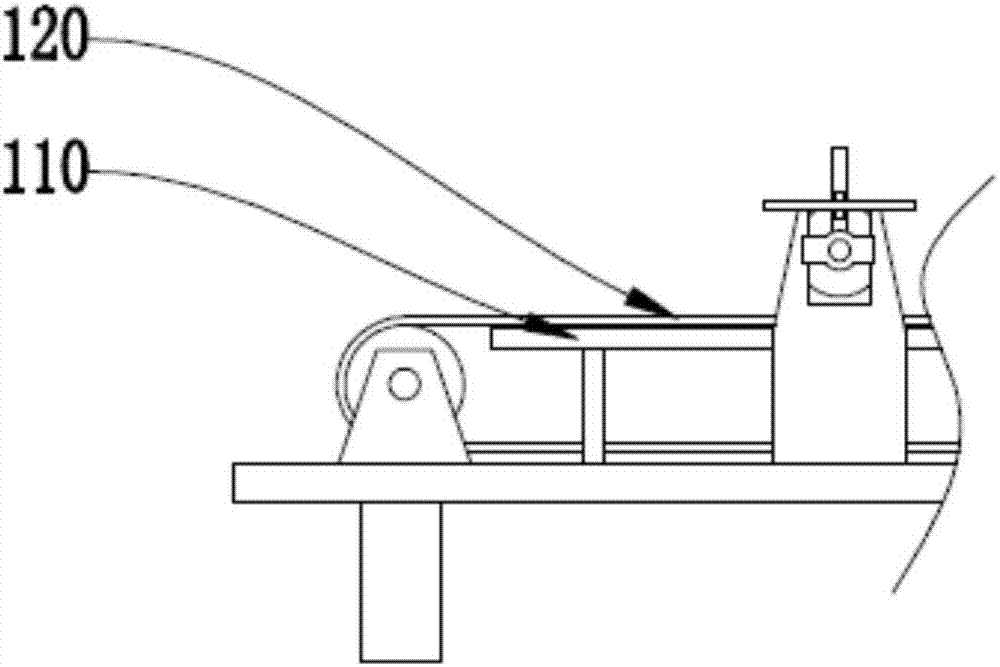

[0034] Such as Figure 1-5 As shown, a sandpaper grinding machine for ceramic tiles includes a grinding device 200, the grinding device 200 includes a roller frame 400 and a rotating roller 210, and also includes a thousand-leaf sandpaper roller B;

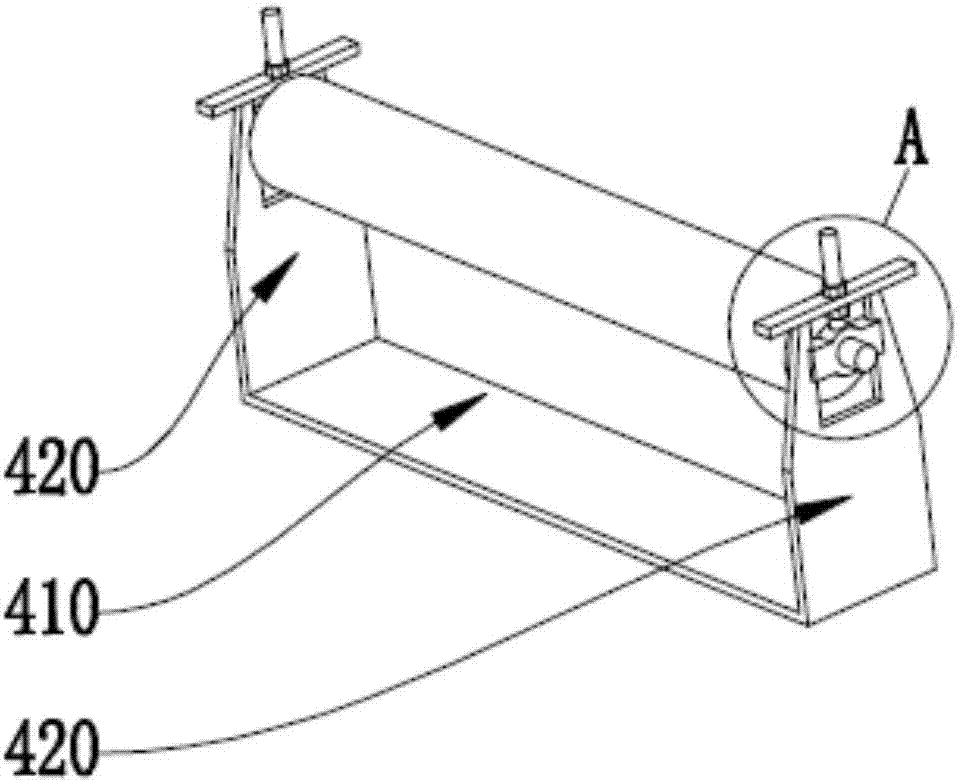

[0035] The Chiba sandpaper roller B is set and fixed on the rotating roller 210. The Chiba sandpaper roller B includes a sandpaper sheet / cloth B1 and a roller B2. One end of the sandpaper sheet / cloth B1 is fixed on the roller Roll surface of B2;

[0036] The roller frame 400 includes an adjustable side plate 420, the rotating roller 210 is horizontally arranged between the two adjustable side plates 420, and the two ends of the rotating roller 210 are respectively rotated and installed on the adjustable side plates on both sides. 420;

[0037] A dri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap