Preparation method of nano-magnesium hydroxide

A nano-magnesium hydroxide and sodium hydroxide technology, which is applied in nanotechnology, calcium/strontium/barium oxide/hydroxide, etc., can solve the problem of large particle size of nano-magnesium hydroxide, long filtration time, long process flow, etc. problem, to achieve the effect of good product performance, uniform distribution, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

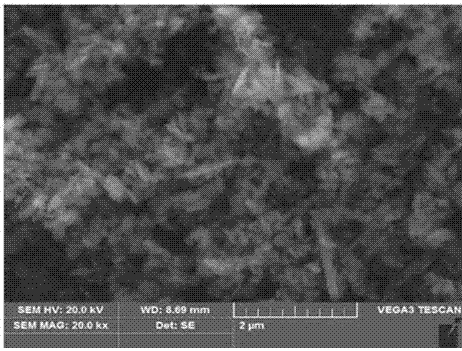

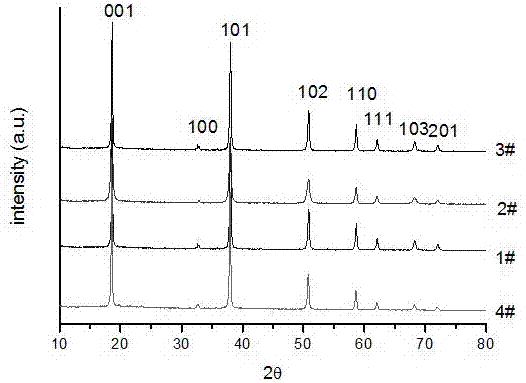

Image

Examples

Embodiment 1

[0029] 1) Take by weighing 50.8g of magnesium chloride hexahydrate, and use a 500mL volumetric flask to prepare a solution of 0.5mol / L;

[0030] 2) Weigh 0.18 g of polyethylene glycol 6000 and dissolve it in 20 mL of water to prepare a polyethylene glycol 6000 aqueous solution with a concentration of 9 g / L.

[0031] 3) Weigh 20 g of sodium hydroxide and prepare a 1.0 mol / L solution with a 500 mL volumetric flask.

[0032] 4) Add 10 mL of ammonia water with a concentration of 14 mol / L to 40 mL of sodium hydroxide with a concentration of 1.0 mol / L, and ultrasonically disperse for 1 hour to obtain a mixed alkali.

[0033] 5) Under an ultrasonic field, add 15 mL of an aqueous solution of polyethylene glycol 6000 with a concentration of 9 g / L to the mixed alkali dropwise at a speed of 4 mL / min. After the dropwise addition, continue ultrasonic dispersion for 0.5h.

[0034] 6) Under the ultrasonic field, add 150 mL of magnesium chloride aqueous solution with a concentrat

Embodiment 2

[0038] 1) Take by weighing 50.8g of magnesium chloride hexahydrate, and use a 500mL volumetric flask to prepare a solution of 0.5mol / L;

[0039] 2) Weigh 0.18 g of polyethylene glycol 6000 and dissolve it in 20 mL of water to prepare a polyethylene glycol 6000 aqueous solution with a concentration of 4.5 g / L.

[0040] 3) Weigh 20 g of sodium hydroxide and prepare a 1.0 mol / L solution with a 500 mL volumetric flask.

[0041] 4) Add 10 mL of ammonia water with a concentration of 14 mol / L to 10 mL of sodium hydroxide with a concentration of 1.0 mol / L, and ultrasonically disperse for 0.75 h to obtain a mixed base.

[0042] 5) Under an ultrasonic field, add 15 mL of an aqueous solution of polyethylene glycol 6000 with a concentration of 4.5 g / L to the mixed alkali dropwise at a speed of 3 mL / min. After the dropwise addition, continue to ultrasonically disperse for 0.75h.

[0043] 6) Under the ultrasonic field, add 150 mL of magnesium chloride aqueous solution with a co

Embodiment 3

[0047] 1) Take by weighing 50.8g of magnesium chloride hexahydrate, and use a 500mL volumetric flask to prepare a solution of 0.5mol / L;

[0048] 2) Weigh 0.18g of polyethylene glycol 6000 and dissolve it in 20mL of water to prepare an aqueous solution of polyethylene glycol 6000 with a concentration of 18g / L.

[0049] 3) Weigh 20 g of sodium hydroxide and prepare a 1.0 mol / L solution with a 500 mL volumetric flask.

[0050] 4) Add 10 mL of ammonia water with a concentration of 14 mol / L to 25 mL of sodium hydroxide with a concentration of 1.0 mol / L, and ultrasonically disperse for 0.5 h to obtain a mixed base.

[0051] 5) Under an ultrasonic field, 15 mL of an aqueous solution of polyethylene glycol 6000 with a concentration of 18 g / L was added dropwise to the mixed alkali at a speed of 5 mL / min. After the dropwise addition, continue to ultrasonically disperse for 1 h.

[0052] 6) Under an ultrasonic field, add 150 mL of an aqueous solution of magnesium chloride wi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap