Seed-production corn male parent cutting and laying machine

A technology for making seed corn and placing machine, which is applied in the field of agricultural machinery, can solve the problems of increased seed production cost, low operation efficiency, reduced market competitiveness of corn seeds, etc., and achieves the effect of reducing production cost and improving operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

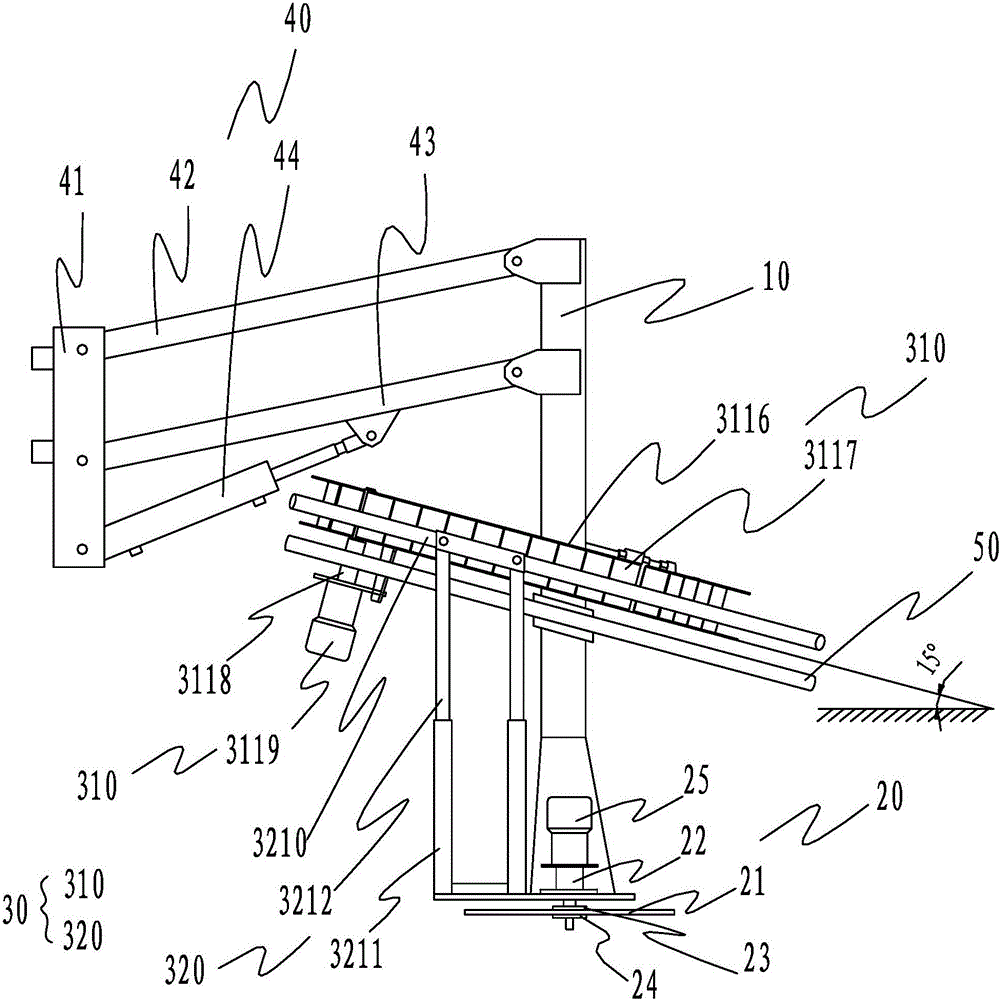

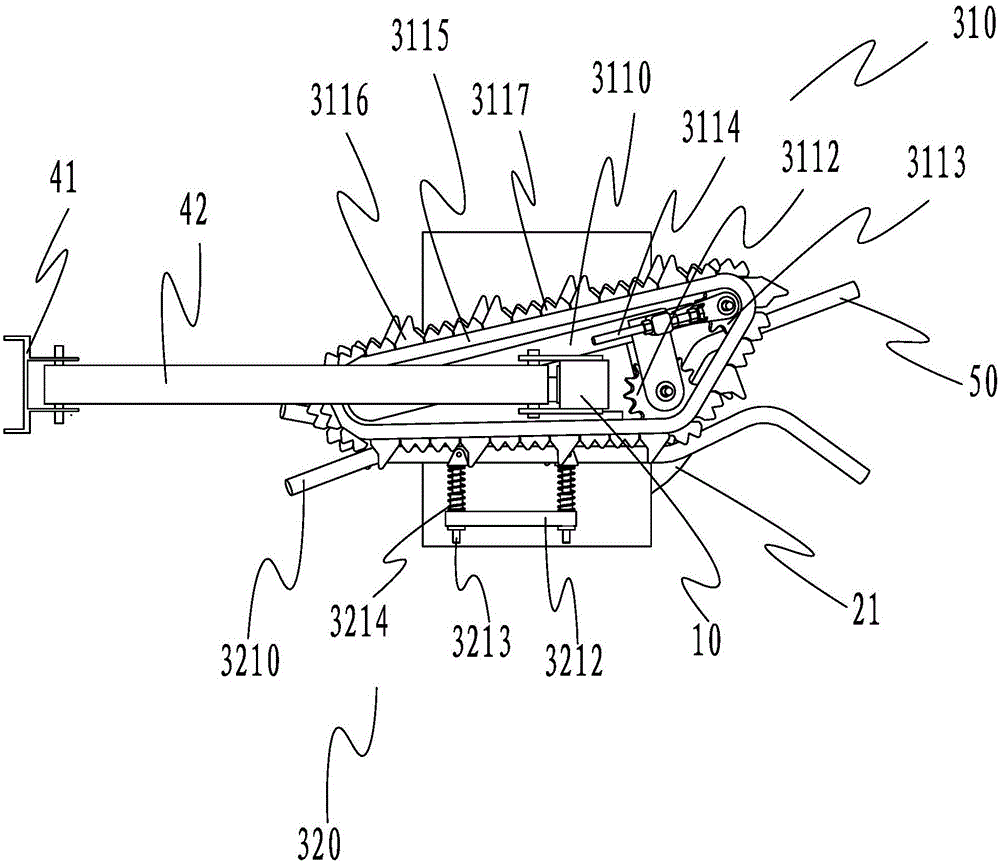

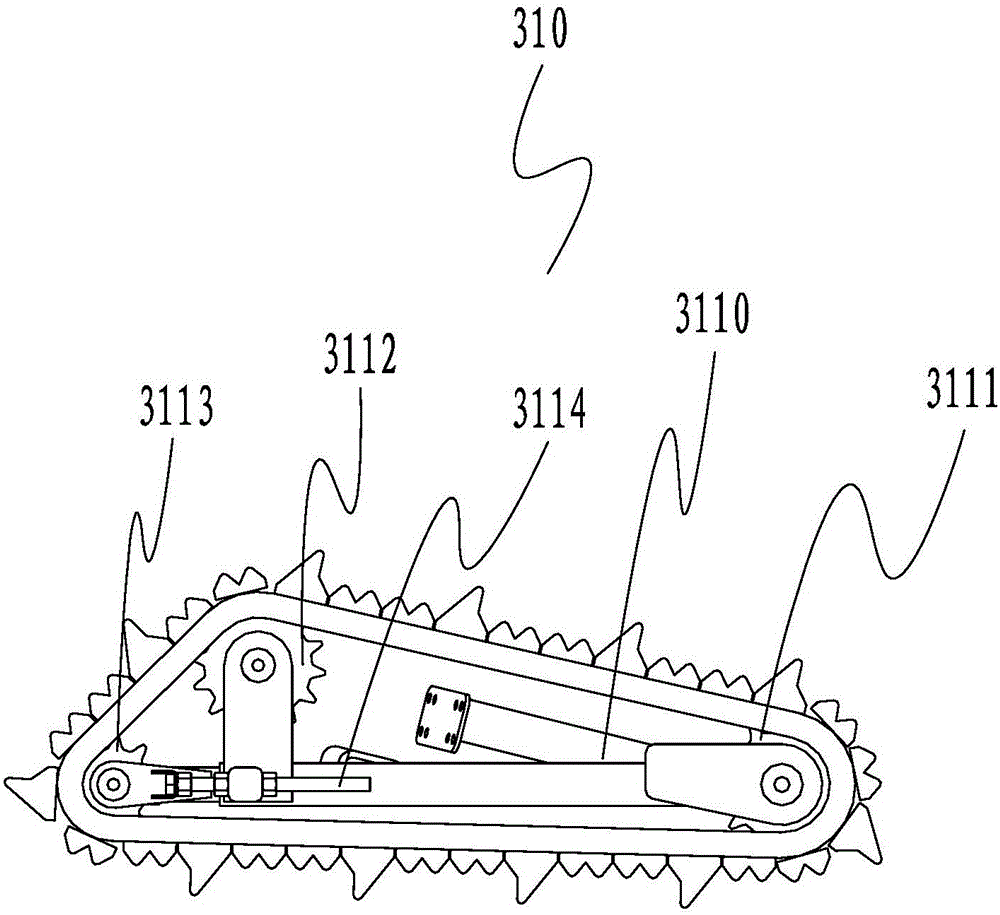

[0075] see figure 1 and figure 2 , figure 1 It is a structural schematic diagram of an embodiment of the present invention, figure 2 for figure 1 top view. The maize male parent excision and laying machine for seed production of the present invention includes: a frame 10 , a cutting mechanism 20 , a clamping and conveying mechanism 30 and a straw 50 . Wherein, the cutting mechanism 20 is arranged on the bottom of the frame 10, and is used to cut the male parent plant of corn for seed production. The bottom of the frame 10; the blade 21 is preferably fixed on the support seat 22 by the upper clamping plate 23 and the lower clamping plate 24 of the blade, and is used for cutting the male parent plant of the seed production corn; and the driving motor 25 is installed on the The upper end of the support base 22 is also connec

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap