Hydraulic liftable device of traction bed

A lifting device and traction bed technology, applied in the field of traction beds, can solve problems such as unfavorable installation and disassembly, inability to ensure the stability of lifting, and insufficient comfort in use, and achieve convenient disassembly and assembly, user-friendly use, comfortable lifting and humanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

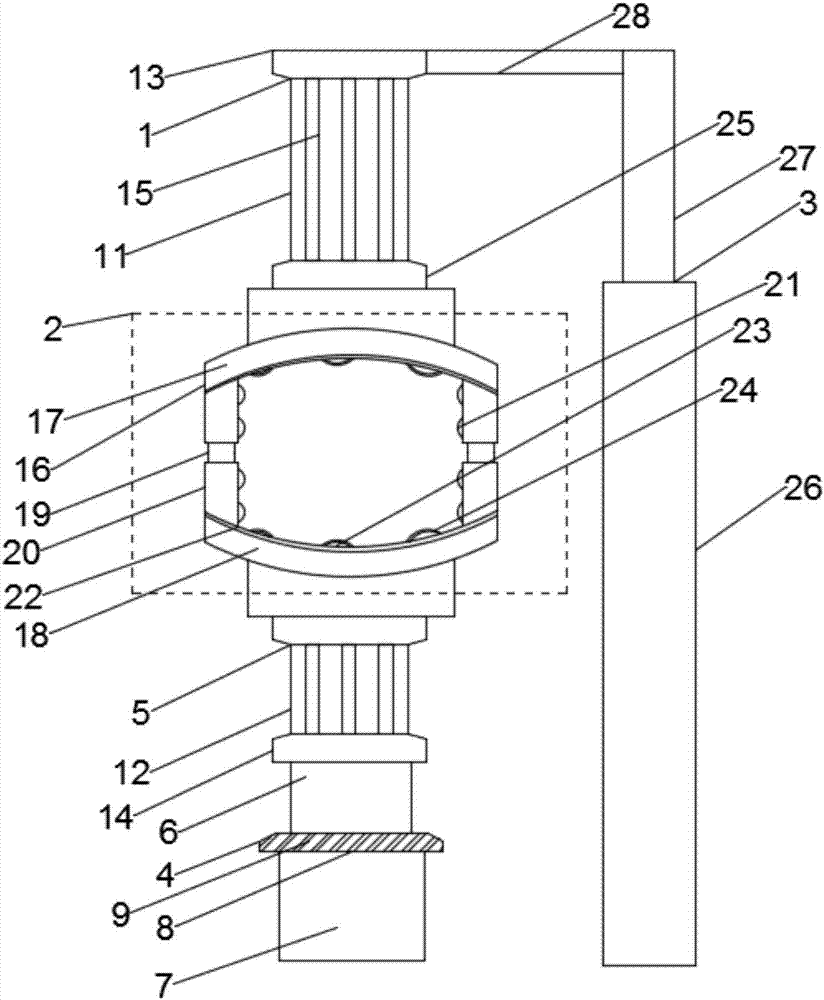

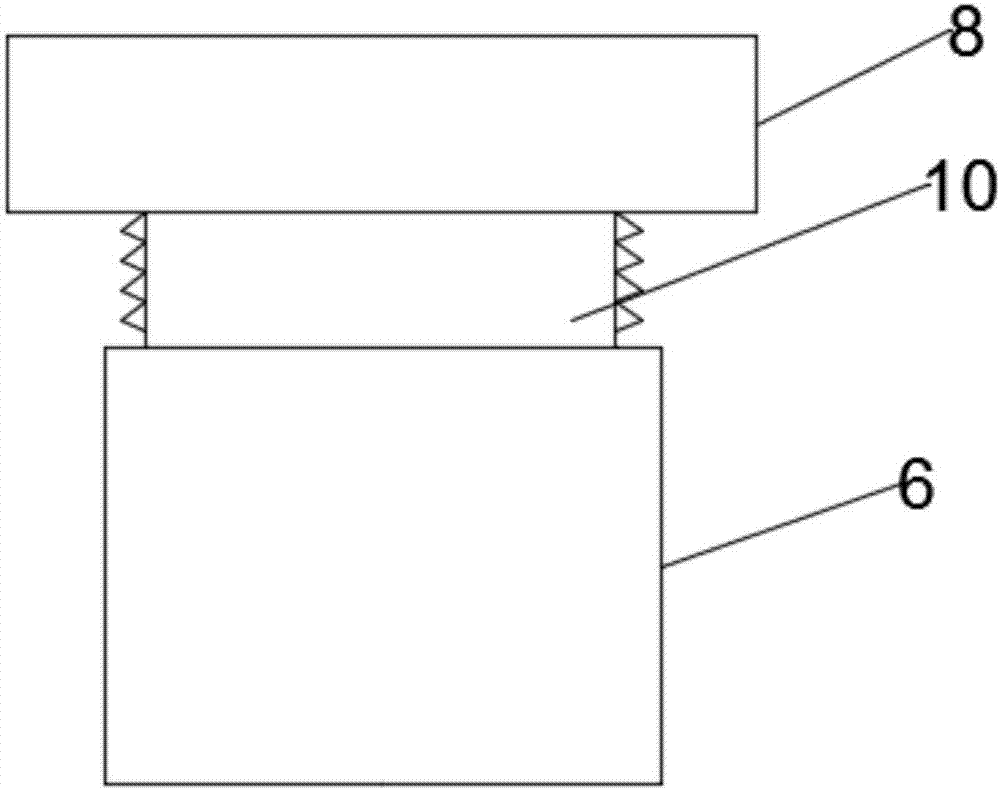

[0019] see figure 1 , figure 2 , the present invention provides a technical solution: a hydraulic liftable device for a traction bed, including an adjustment device 1, a mounting device 2 and a support rod 3, the adjustment device 1 includes an adjustment rod 4 and a buffer frame 5, and the adjustment rod 4 includes a fixed rod 6 and a hydraulic rod 7, the hydraulic rod 7 and the fixed rod 6 are connected together through a connecting seat 8, the buffer frame 5 includes an upper buffer rod 11 and a lower buffer rod 12, and the upper buffer rod 11 and the support rod 3 are connected together, the top of the fixed rod 6 is equipped with a mounting seat 14, the lower buffer rod 12 and the mounting seat 14 are connected together, the upper buffer rod 11 and the lower buffer rod 12 adopt the same structure, Both the upper buffer rod 11 and the lower buffer rod 12 are composed of several spring rods 15, which are arranged in a ring between the spring rods 15, and the installation dev

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap