Novel double-layer mechanical lifting garage

A mechanical, double-layer technology, applied in building types, buildings where cars are parked, buildings, etc., can solve problems such as inconvenience, and achieve the effect of low manufacturing cost and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

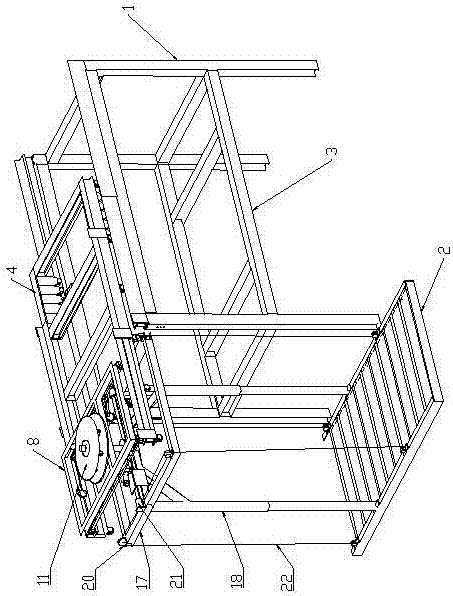

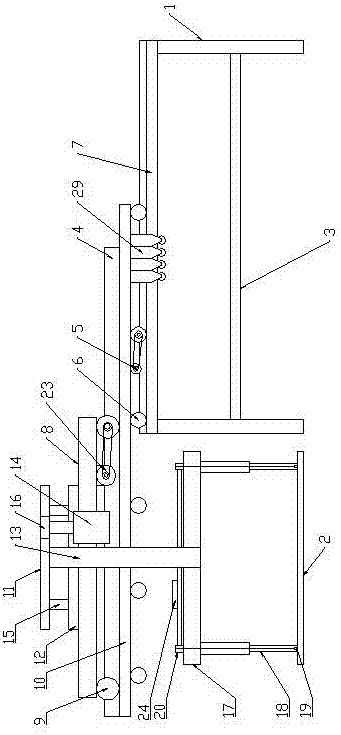

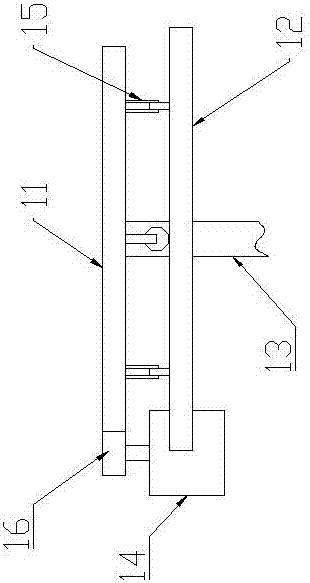

[0019] Such as Figure 1 to Figure 6 As shown, a novel double-deck mechanical lifting garage includes a main body support 1, a first horizontal linear motion device, a second horizontal linear motion device, a rotating mechanism, a vertical lifting mechanism and a vehicle-carrying plate 2, and the main body support 1 The waist is provided with a support frame 3, and the support frame 3 divides the main body support 1 into two parking spaces up and down. A horizontal linear motion device is arranged on the upper end of the main body bracket 1 and moves left and right on the upper end of the main body bracket 1. The second horizontal linear motion device is arranged on the upper end surface of the first horizontal linear motion device and moves left and right on the first horizontal linear motion device. The rotation mechanism It is arranged on the second horizontal linear motion device, the vertical lifting mechanism is arranged at the lower end of the rotating mechanism, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap