Polyvinyl alcohol aldehyde acetal group solid lubricant and preparation method thereof

A polyvinyl acetal-based, polyvinyl acetal-based resin technology, applied in the field of polyvinyl acetal-based solid lubricants and their preparation, can solve problems such as increased management difficulty, reduced lubrication effect, and polluted working environment , to achieve the effect of simple process, low shear strength and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

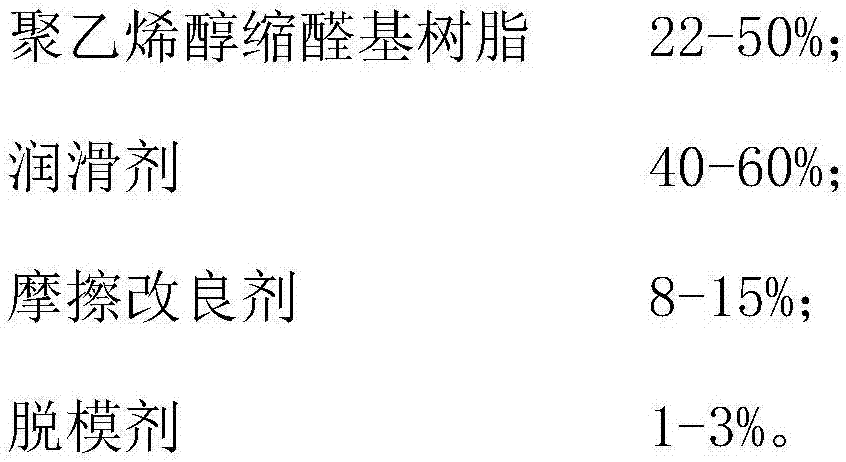

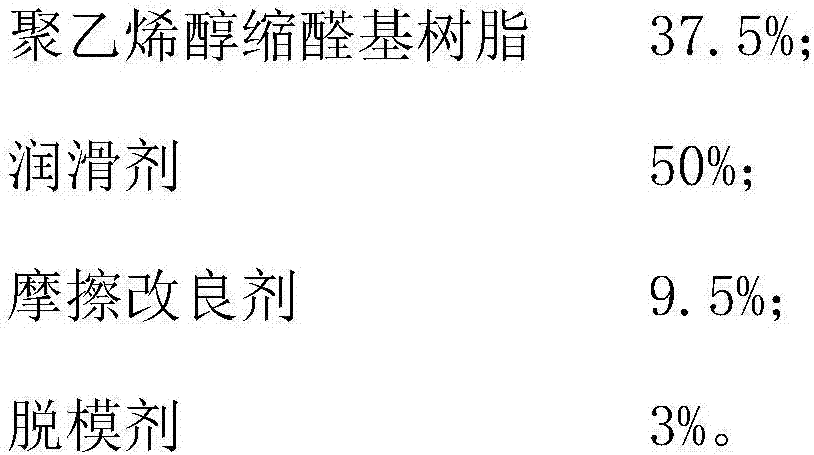

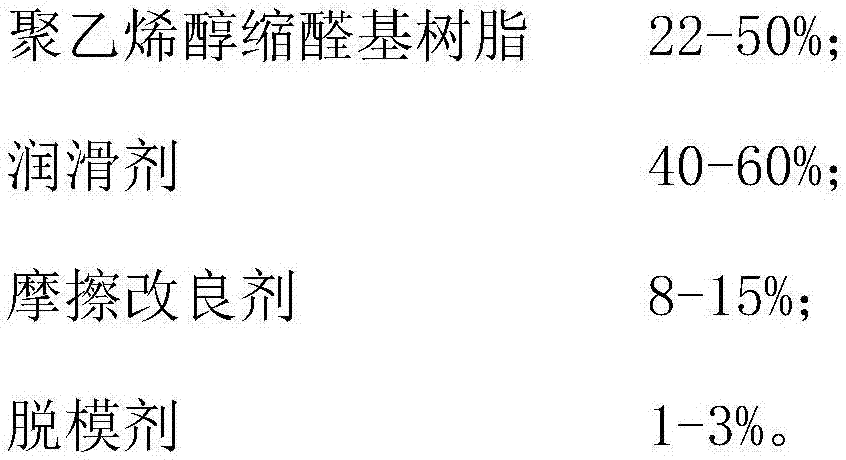

[0025] A kind of polyvinyl acetal based solid lubricant, its formula dosage sees the following table 1, and its preparation method comprises the steps:

[0026] 1) Stir the polyvinyl butyral, graphite, talcum powder and polyethylene wax to obtain a mixed raw material;

[0027] 2) Vacuum pumping process: Add the mixed raw materials into the mold, put the mold into a vacuum drying oven after closing the mold, keep the temperature at 85°C, keep the pressure at 0.01MPa for 10 minutes, and pump out the air in the material;

[0028] 3) Hot pressing process: put the mold treated in step 2) into a flat vulcanizing machine for hot pressing, the hot pressing temperature is 250°C, the pressure is 30MPa, the holding time is 2h, then cooling, demoulding, and the polymer Vinyl acetal based solid lubricant.

[0029] The consumption of each raw material component in the embodiment of table 1

[0030] components

[0031] The operating temperature range of the polyvinyl acetal-based so

Embodiment 2

[0033] A kind of polyvinyl acetal based solid lubricant, its formula dosage sees the following table 1, and its preparation method comprises the steps:

[0034] 1) Stir the polyvinyl butyral, graphite, talcum powder and polyethylene wax to obtain a mixed raw material;

[0035] 2) Vacuum pumping process: Add the mixed raw materials into the mold, put the mold into a vacuum drying oven after closing the mold, keep the temperature at 70°C, keep the pressure at 0.01MPa for 10 minutes, and pump out the air in the material;

[0036] 3) Hot pressing process: put the mold treated in step 2) into a flat vulcanizing machine for hot pressing, the hot pressing temperature is 250°C, the pressure is 30MPa, the holding time is 2h, then cooling, demoulding, and the polymer Vinyl acetal based solid lubricants;

[0037] 4) The polyvinyl acetal-based solid lubricant obtained in step 3) is vacuum-impregnated with paraffin wax as the impregnating agent, and the process parameters are as follows: an

Embodiment 3

[0042] A kind of polyvinyl acetal based solid lubricant, its formula dosage sees the following table 1, and its preparation method comprises the steps:

[0043] 1) Stir the polyvinyl formal, graphite, talcum powder and polyethylene wax to obtain a mixed raw material;

[0044] 2) Vacuum pumping process: Add the mixed raw materials into the mold, put the mold into a vacuum drying oven after closing the mold, keep the temperature at 100°C, keep the pressure at 0.01MPa for 10 minutes, and pump out the air in the material;

[0045] 3) Hot pressing process: put the mold treated in step 2) into a flat vulcanizing machine for hot pressing, the hot pressing temperature is 200°C, the pressure is 30MPa, and the holding time is 2h, then cooling and demoulding, the poly Vinyl acetal based solid lubricants;

[0046] 4) The polyvinyl acetal-based solid lubricant obtained in step 3) is vacuum impregnated with asphalt as the impregnating agent, and the process parameters are as follows: impregna

PUM

| Property | Measurement | Unit |

|---|---|---|

| L | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap