Device and method for gluing grinding wheel and grinding wheel disc with double-faced tape

A technology of double-sided adhesive and grinding wheel disc, which is applied to the device for fixing the grinding wheel, the components of the grinding machine tool, and the metal processing equipment. Strong, easy to operate and safe, smooth bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

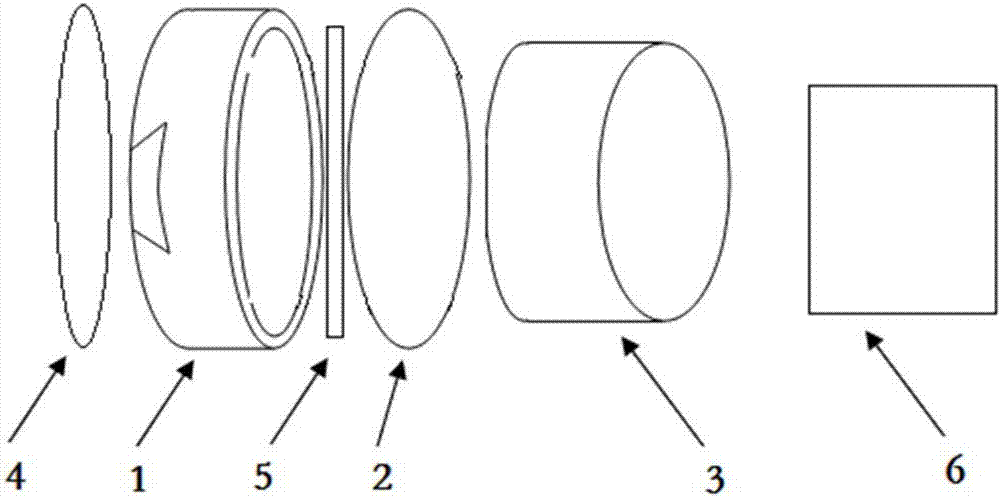

[0030] Such as figure 1 As shown, a device for bonding a grinding wheel and a grinding wheel disc with double-sided adhesive wherein the device of the present invention includes: a sanding mechanism 4 for cleaning the grinding wheel disc 1; a waterproof double-sided adhesive bonding mechanism for bonding the grinding wheel 3 to the cleaning wheel The bonded grinding wheel disc 1 is bonded; the pressurizing mechanism 6 is used to pressurize the bonded grinding wheel 3 and the grinding wheel disc 1 to stabilize the bonding. The waterproof double-sided adhesive 2 used in the waterproof double-sided adhesive bonding mechanism is a polyacrylate double-sided foam tape, and the mechanism also includes an adhesive 5 for stabilizing the waterproof double-sided adhesive.

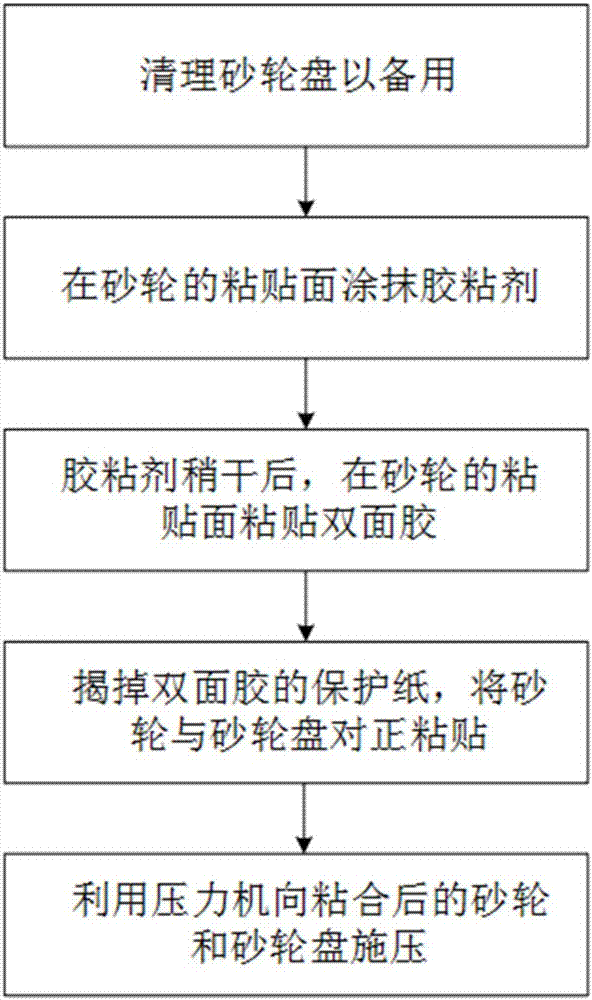

[0031] Such as figure 2 Shown, method of the present invention mainly comprises the following steps:

[0032] Step 1) Fix the grinding wheel first, cut off the remaining grinding wheel with a cutter, soak the grinding

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap