Oil injector with double air inlet channels

A fuel injector and double-injection technology, which is applied in the direction of fuel injection control, machine/engine, fuel injection device, etc., can solve the problems of unfavorable fuel consumption, reduction, engine power waste, etc., to achieve supply, fast response speed, Flexible and changeable fuel injection schedule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

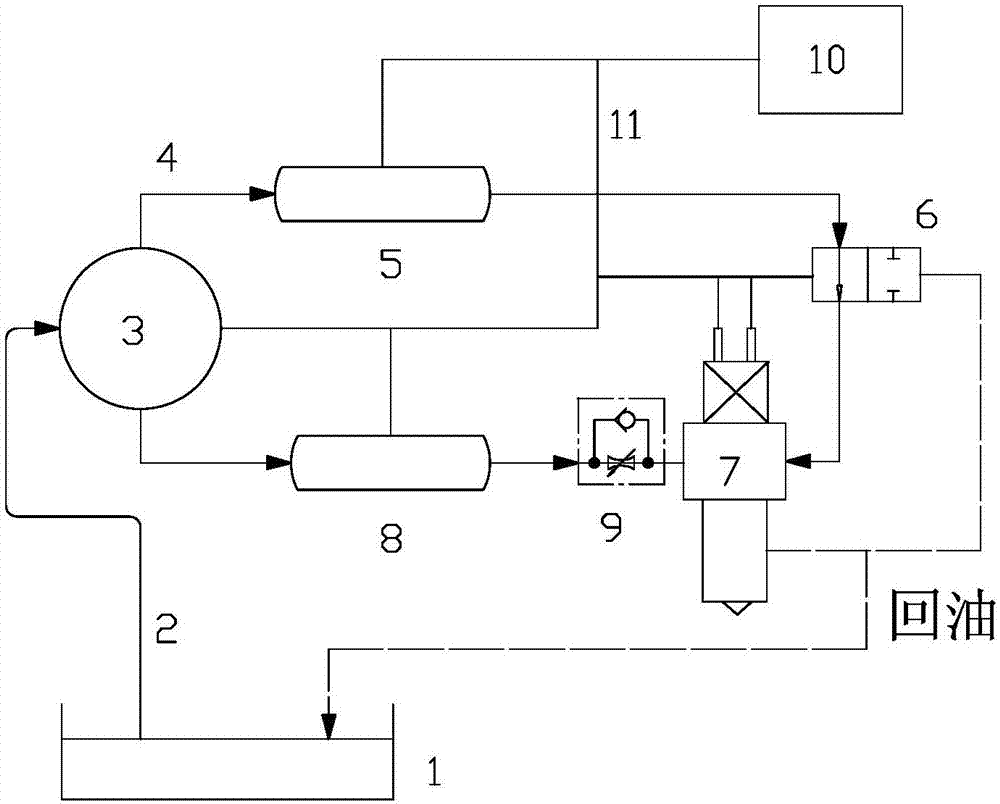

[0026] In order to be able to realize the flexible switching of the two injection pressures in a single injection cycle, such as figure 1 As shown, a fuel supply system for a diesel engine includes a fuel tank 1, a low-pressure fuel pipe 2, a high-pressure fuel pump 3, a high-pressure fuel pipe 4, a high-pressure common rail pipe 5, a middle and low-pressure common rail pipe 8, a solenoid switch valve 6, and a dual-inlet fuel injection port. Oiler 7, check valve with orifice 9, ECU (Electronic Control Unit) 10 and electronic control wiring harness 11;

[0027] Fuel tank 1 is connected to high pressure fuel pump 3 through low pressure fuel pipe 2; high pressure fuel pump 3 is connected to high pressure common rail pipe 5 and medium and low pressure common rail pipe 8 through high pressure fuel pipe 4; high pressure fuel pump 3 is an electronically controlled multi-cylind

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap