Copper alloy containing metal ceramic coating, and preparation method and application thereof

A cermet coating and copper alloy technology, which is applied to mechanical equipment, heating inorganic powder coating, hot gas variable capacity engine devices, etc., can solve the problems of strictly prohibited technology export, achieve simple preparation process, ensure stability, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

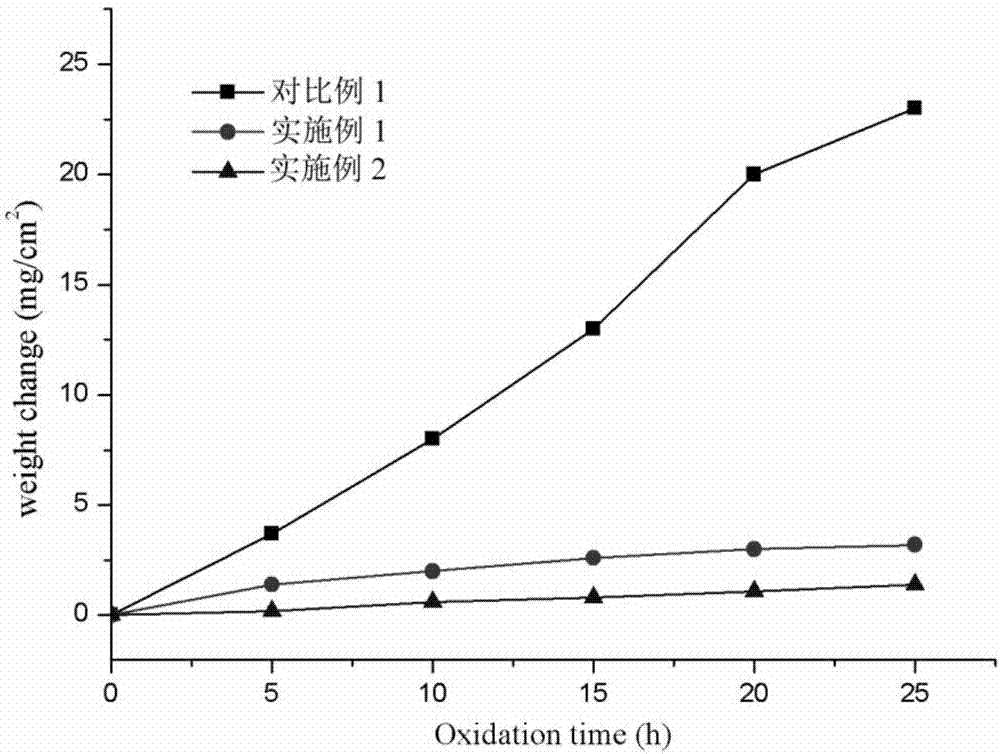

Embodiment 1

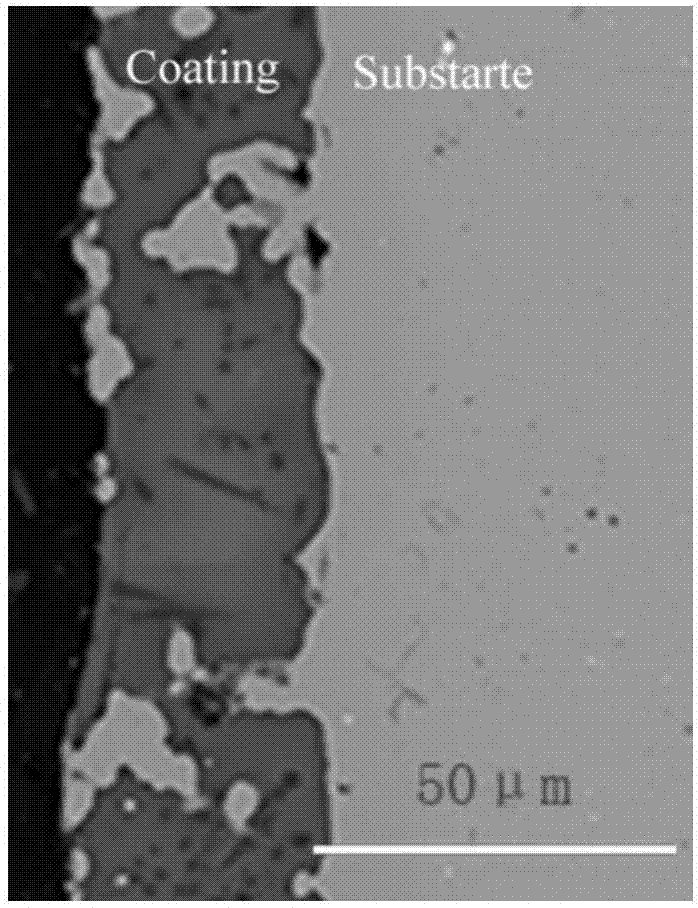

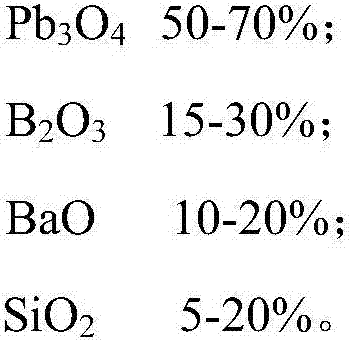

[0049] According to glass composition 65Pb 3 o 4 : 14B 2 o 3 : 16BaO: 5SiO 2 Weigh the oxides of each component, mix the weighed powders evenly, melt and keep it at 1200°C for 2.5 hours, then pour the melt into water to obtain block glass. Block glass is crushed, and ball milled in a zirconia ball mill jar for 30 hours to obtain ceramic frit (the particle size of the ceramic frit is 0.1-40 microns);

[0050] The ceramic glass frit, metal nickel powder, and clay were mixed and ball-milled for 10 hours at a mass ratio of 1:1:0.2, and then deionized water was added to prepare a cermet water-based slurry, and the viscosity was adjusted to 10‐14s. The particle size of the nickel metal powder is 0.5-2 microns.

[0051] After degreasing the copper alloy parts of the engine, ultrasonically clean them with distilled water for 30 minutes and dry them.

[0052] The prepared water-based slurry was dispersed by ultrasonic vibration for 1 hour, and then the copper alloy parts were immers

Embodiment 2

[0056] According to glass composition 55Pb 3 o 4 : 16B 2 o 3 : 11BaO: 18SiO 2 Weigh the oxides of each component, mix the weighed powders evenly, melt and keep it at 1300°C for 3 hours, and then pour the melt into water to obtain block glass. Block glass is crushed, and ball milled in a zirconia ball mill jar for 40 hours to obtain ceramic frit (the particle size of the ceramic frit is 0.1-40 microns);

[0057] The ceramic glass frit, metallic nickel powder, and clay were mixed and ball-milled for 10 hours according to the mass ratio of 1:1.2:0.1, and then deionized water was added to prepare a cermet water-based slurry, and the viscosity was adjusted to 10‐14s. The particle size of the nickel metal powder is 0.5-2 microns.

[0058] After degreasing the copper alloy parts of the engine, ultrasonically clean them with distilled water for 30 minutes and dry them.

[0059] The prepared water-based slurry was dispersed by ultrasonic vibration for 1 hour, and then the copper all

Embodiment 3

[0064] According to glass composition 52Pb 3 o 4 : 28B 2 o 3 : 15BaO: 5SiO 2 Weigh the oxides of each component, mix the weighed powder evenly, melt and keep it at 1100°C for 2 hours, then pour the melt into water to obtain block glass. Block glass is crushed, and ball milled in a zirconia ball mill jar for 30 hours to obtain ceramic frit (the particle size of the ceramic frit is 0.1-40 microns);

[0065] The ceramic glass frit, metallic nickel powder, and clay were mixed and ball-milled for 10 hours at a mass ratio of 1:0.6:0.3, and then deionized water was added to prepare a cermet water-based slurry, and the viscosity was adjusted to 10‐14s. The particle size of the nickel metal powder is 0.5-2 microns.

[0066] After degreasing the copper alloy parts of the engine, ultrasonically clean them with distilled water for 30 minutes and dry them.

[0067] The prepared water-based slurry was dispersed by ultrasonic vibration for 1 hour, and then the copper alloy parts were imme

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap