Combined type bone-meat separating device

A combined technology of bone and meat separation, applied in the direction of solid separation, grading, and processed meat, can solve the problems of high processing cost, incomplete separation of flesh and blood, production cost control, etc., to achieve expanded production cost control and low processing difficulty , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

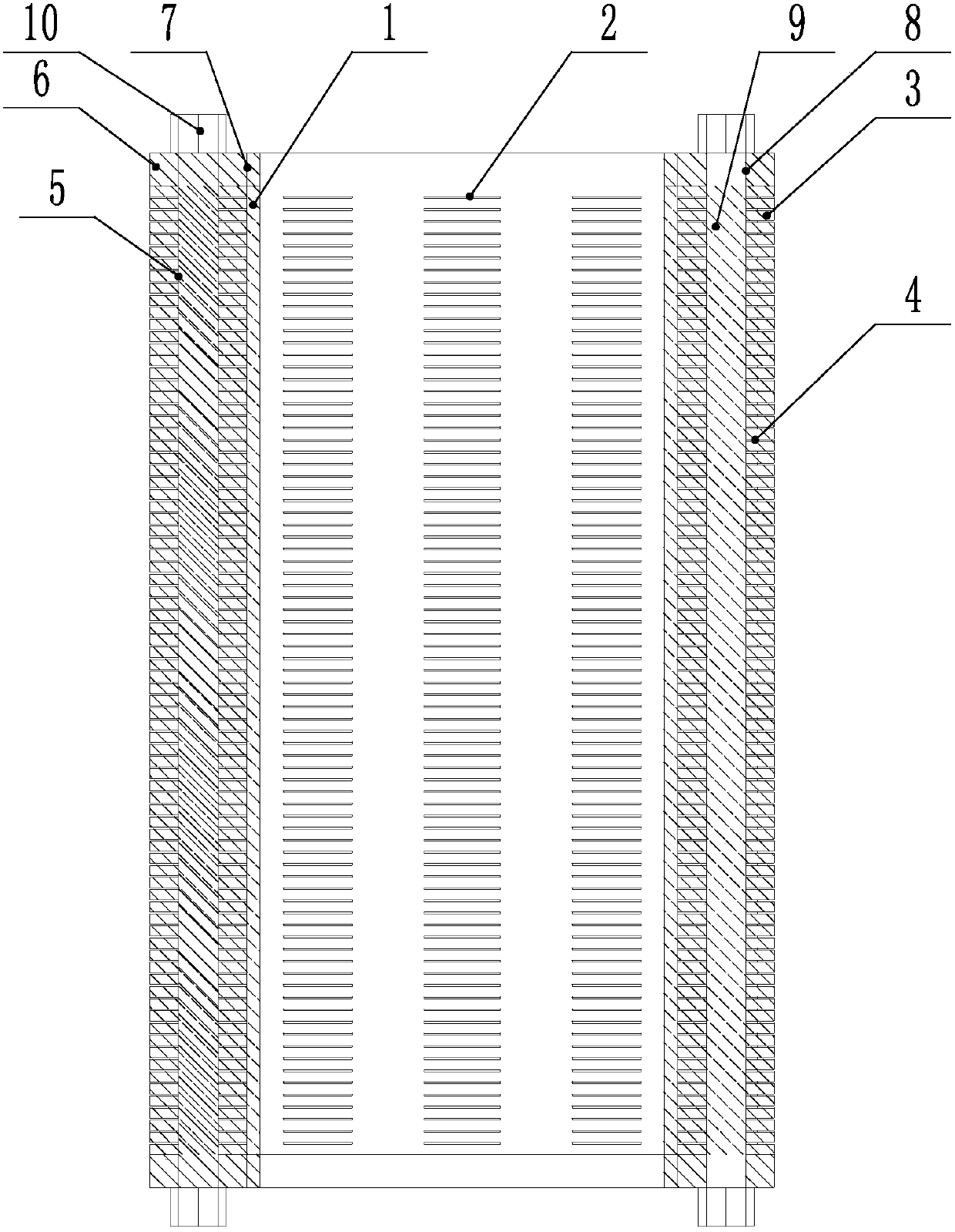

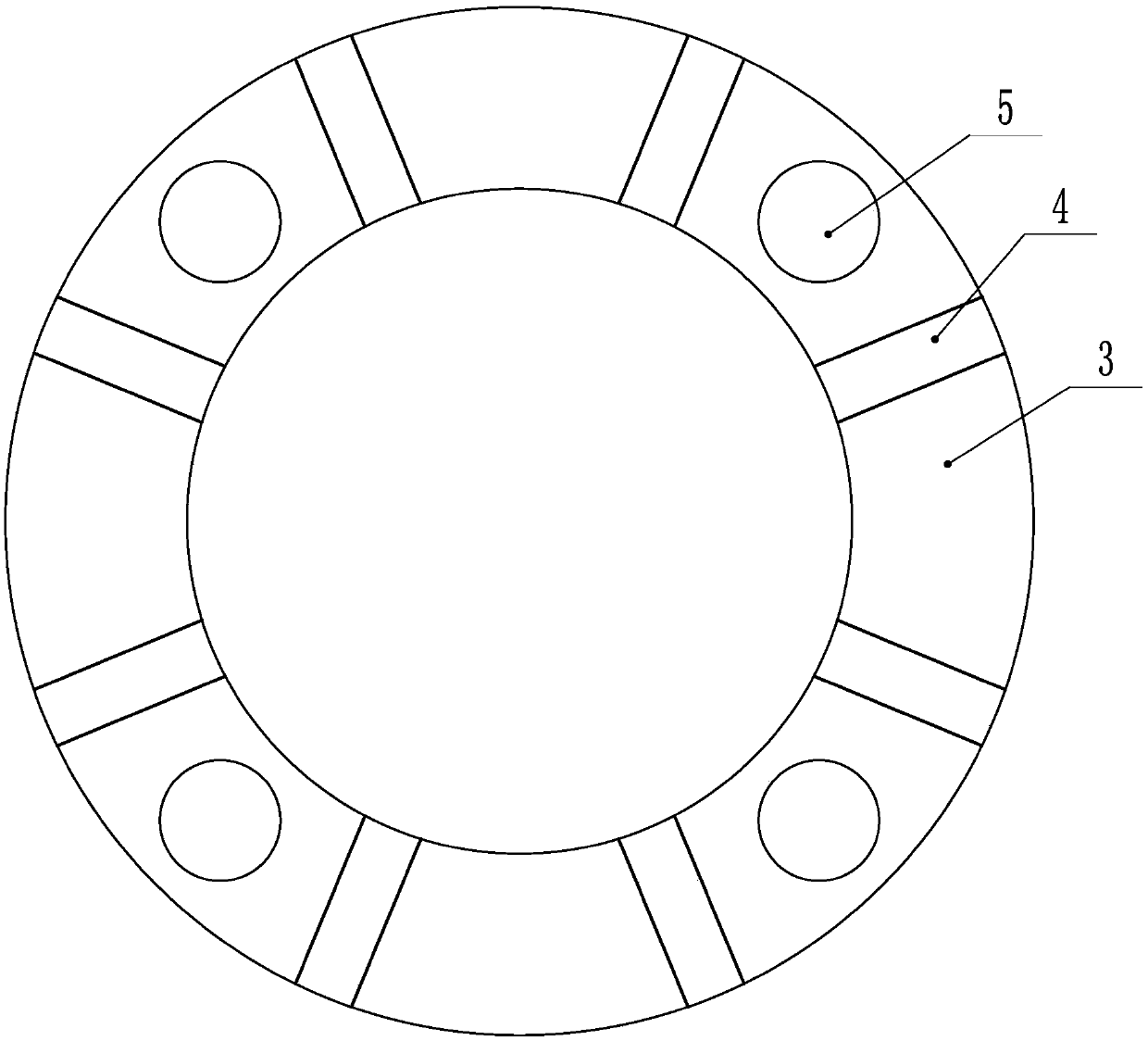

[0014] Such as figure 1 , 2 As shown, the present invention includes an inner cylinder 1, uniformly arranged filter holes 2 are arranged on the wall of the inner cylinder 1, a disc 3 is sleeved on the outside of the inner cylinder 1, a raised partition 4, and a gasket are provided on the disc 3 Screw holes 5 are provided around the inner cylinder 1. Flanges 6 are sleeved on the outer sides of the upper and lower ends of the inner cylinder 1. The contact surface of the flange 6 and the inner cylinder 1 is provided with a thread 7, and the flange 6 is provided with a fixing hole 8. The flange 6 is connected to the disc 3 by the screw 9 and the screw 9 is fixed with the flange 6 by the nut 10. The disc 3 is separated by the partition 4, and there is a gap between the discs 3, and the gap between the discs 3 and the filter Hole 2 corresponds to the shape of the filter channel. The gaps between the discs 3 are staggered with the filter holes 2 to increase the restriction of the passage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap