Automobile rear anti-collision beam optimization method based on CAE (Computer Aided Engineering) crash simulation technology

An optimization method and technology of rear anti-collision beam, applied in geometric CAD, design optimization/simulation, special data processing applications, etc., to achieve the effect of low development cost, meeting performance requirements, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

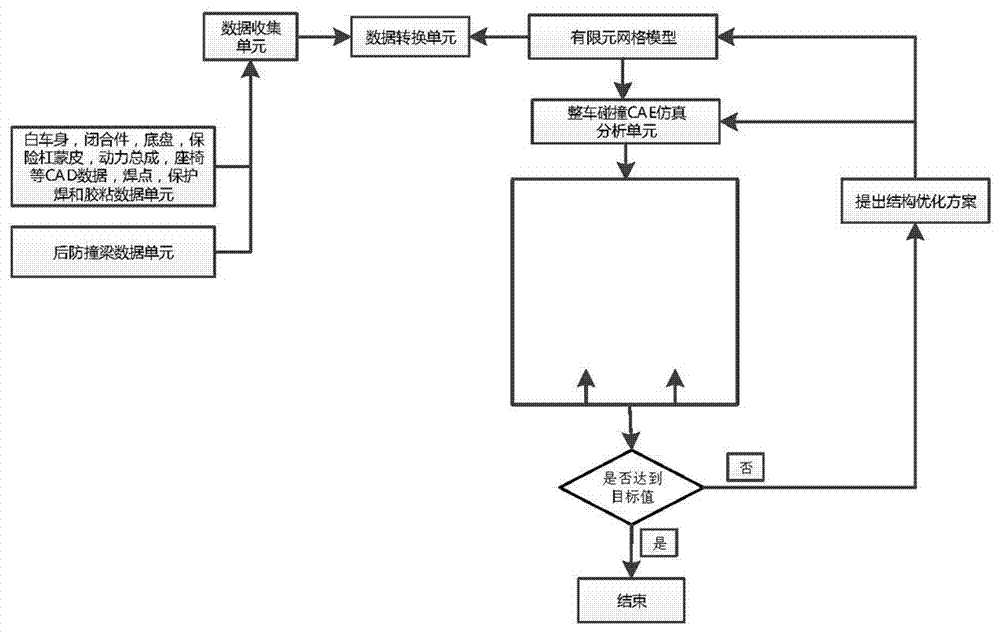

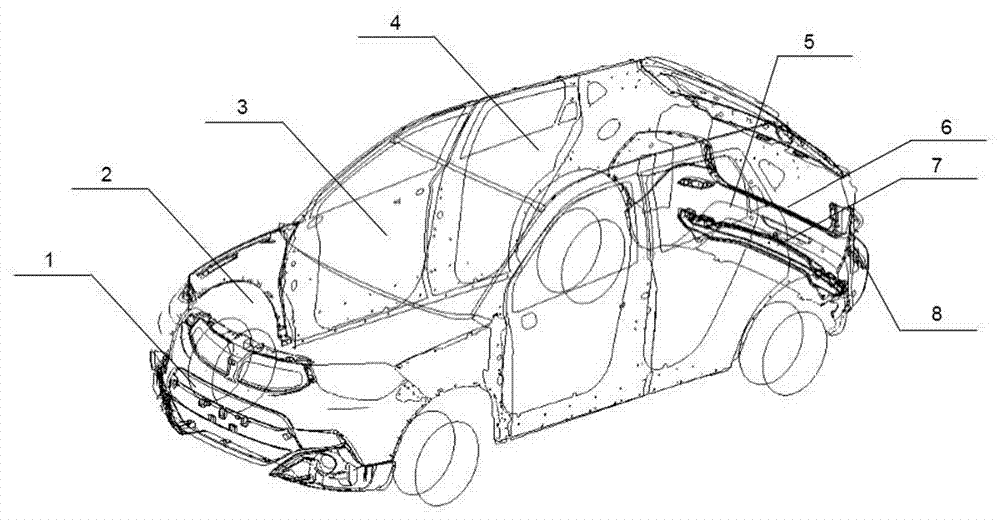

[0016] The invention provides a method for optimizing automobile rear anti-collision beams based on CAE collision simulation technology, which includes CAD data such as body-in-white, closures, chassis, bumper skins, powertrains, seats, solder joints, protective welding and glue For sticky data units, the optimization method includes the following steps:

[0017] (1) The above-mentioned units transfer data to the data collection unit, and the data collection unit transfers the data to the data conversion unit;

[0018] (2) The data conversion unit is the finite element pre-processing ANSA software that converts the data in the data collection unit into the connection format recognized by the software, in which the 3D point of the solder joint data is converted to spotweld, and the protective welding CAD line is converted to spotline. The CAD plane is converted to an adhesive face, the diameter of the solder joint, the interval of the protective welding and the width of the expansion g

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap