Reinforcing method of hollow brick masonry structure

A masonry structure and hollow brick technology, which is applied to building components, building structures, and processing of building materials, etc., can solve the problems of low seismic performance, poor integrity, and low bearing capacity, and achieve improved seismic performance, convenient construction, and reduced energy consumption. The effect of small casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

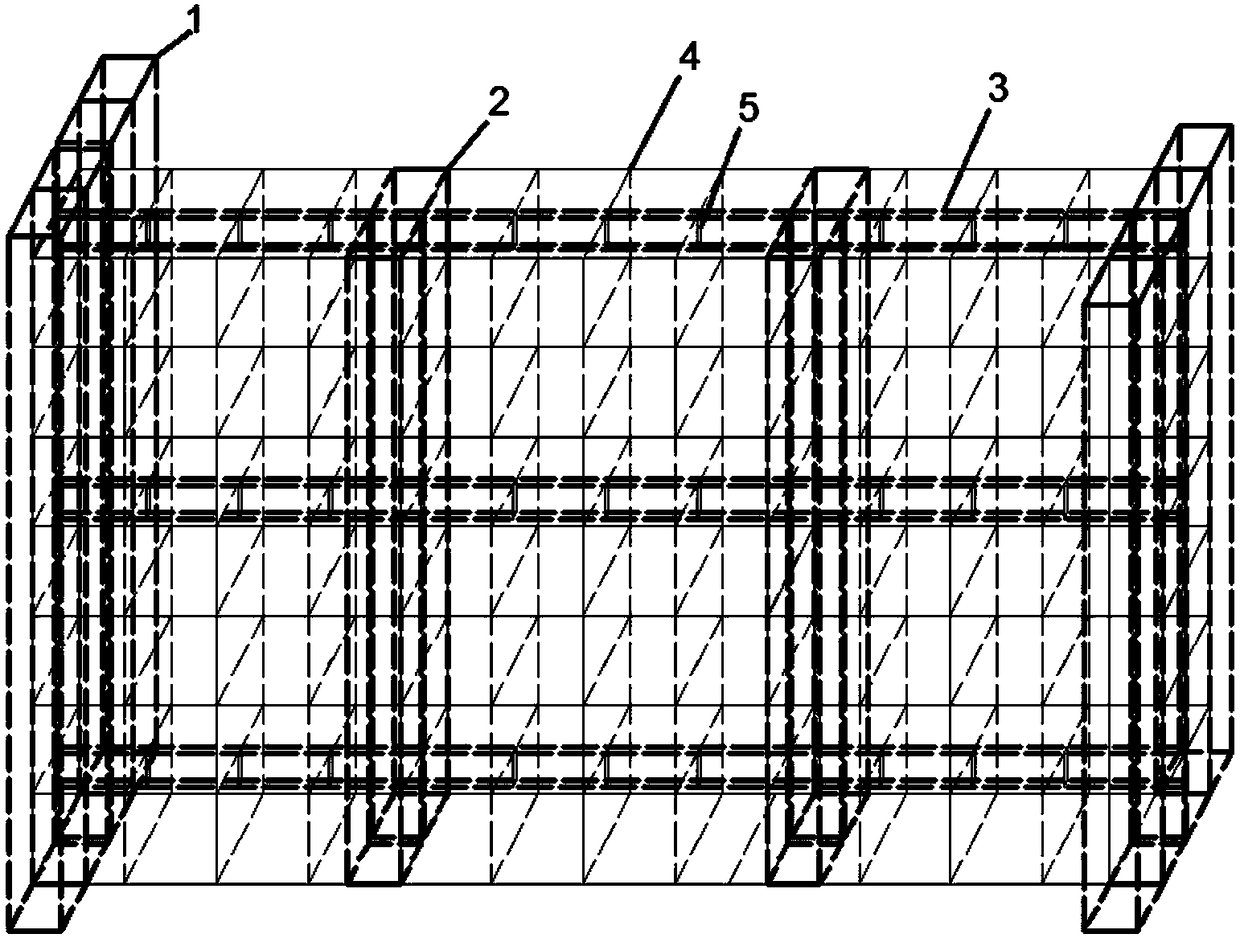

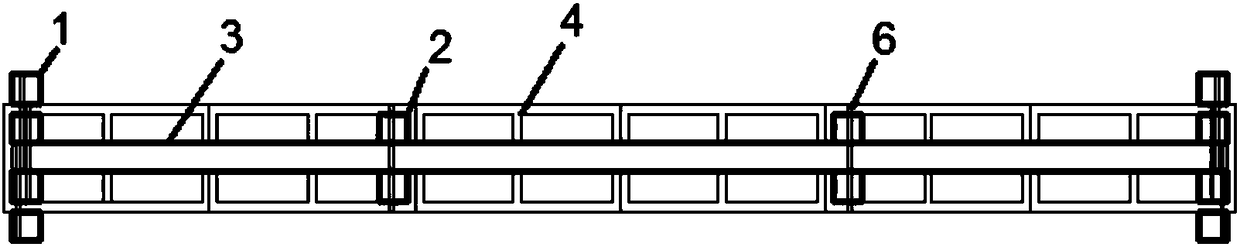

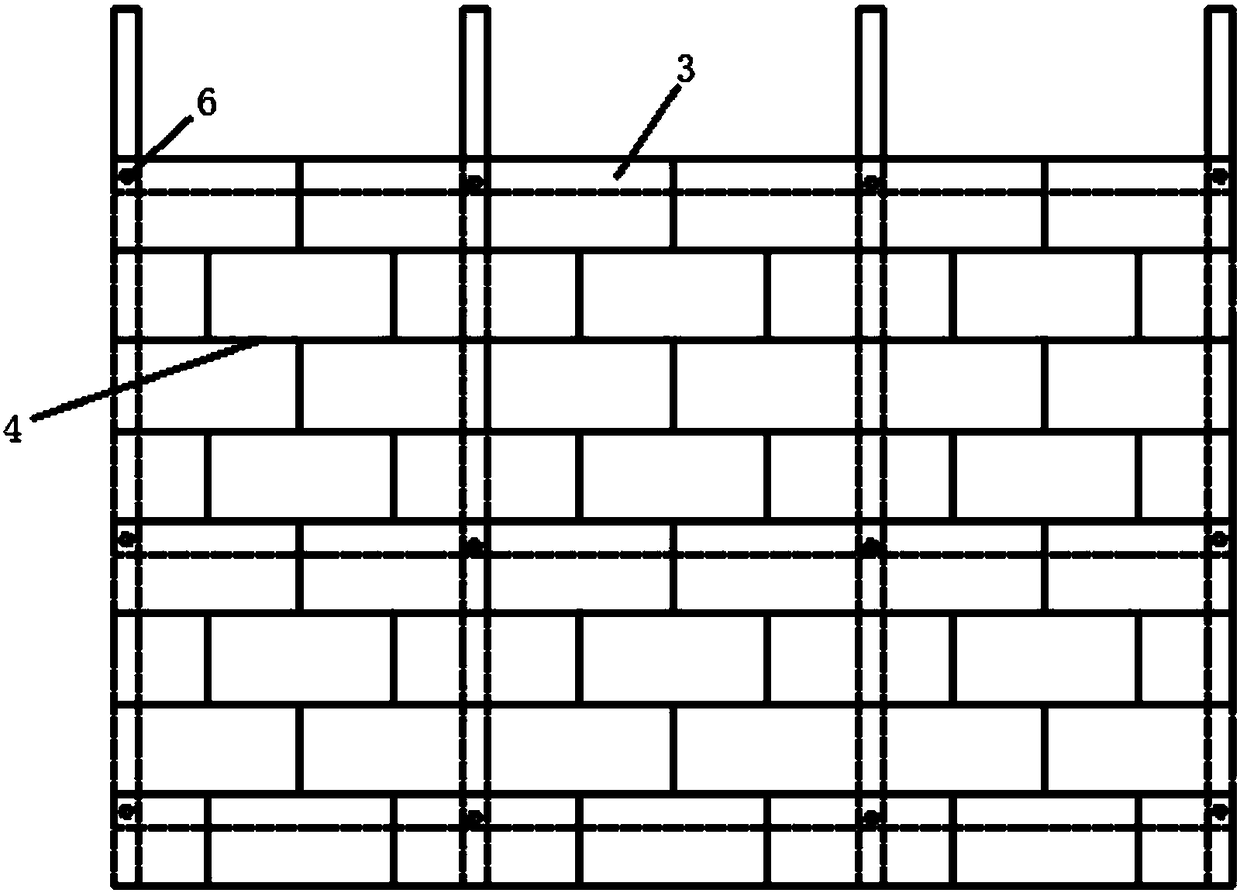

[0032] Figure 1-3 A schematic diagram of a hollow brick masonry structure reinforced by the present invention is shown.

[0033] The reinforcement method of the hollow brick masonry structure comprises the following steps:

[0034] S1, masonry bottom hollow blocks;

[0035] S2 Set up a groove 5 at the position where the wooden frame beam 3 is to be placed in the hollow brick masonry structure 4 on the ground floor. The groove 5 is opened on the upper part of the hollow brick and is located in the middle of the hollow brick masonry structure 4. Specifically, it should be opened before the hollow block is wet. Groove 5, otherwise it is easy to damage the hollow block;

[0036] S3. Place a wooden frame beam 3 in the hollow brick masonry structure 4 with the groove 5, wherein the outer sides of the blocks at both ends of the hollow brick masonry structure 4 are not provided with grooves 5, so as to ensure the hollow brick masonry structure 4 at the corner. carrying capacity. Whe

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Ultimate bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap