Aggregate sampling drill

An aggregate and drill bit technology is applied in the field of concrete production equipment, which can solve the problems of unqualified, low material reclaiming efficiency, and lowering concrete, etc., and achieve the effects of large effective capacity, convenient use and high sampling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the present invention, the technical solutions of the present invention are further described below with reference to the accompanying drawings and embodiments.

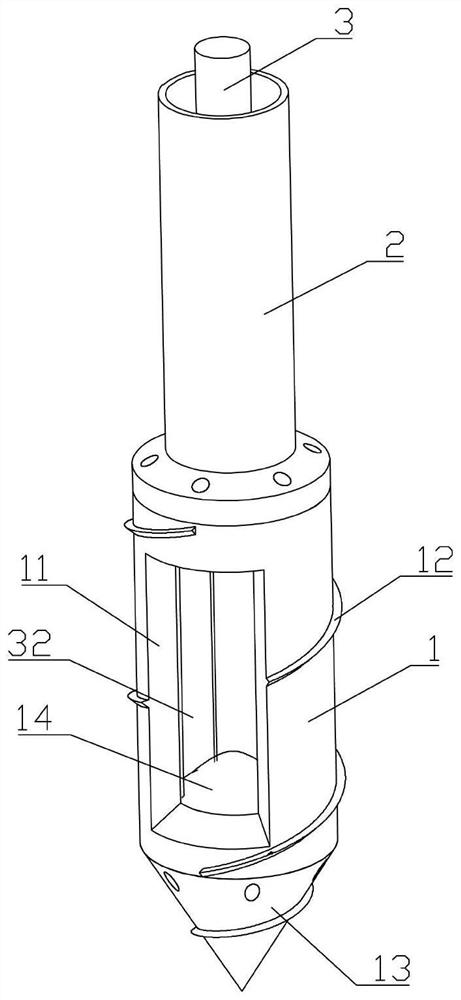

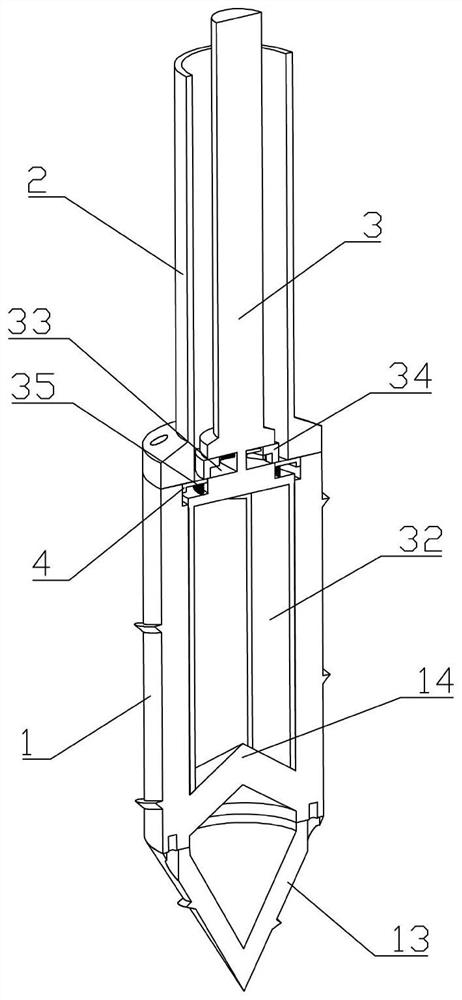

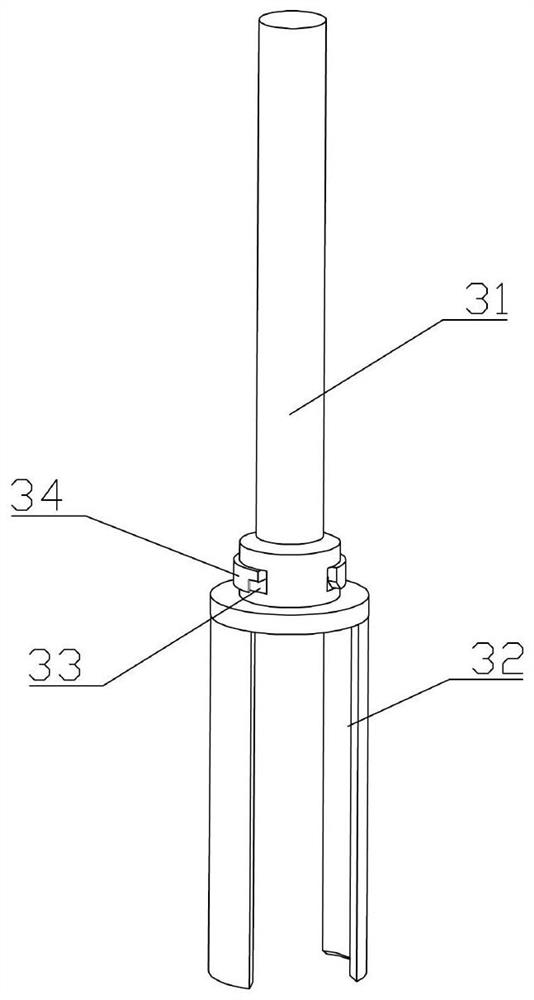

[0035] like Figures 1 to 3 As shown, an aggregate sampling drill includes a cylinder body 1 and a connection cylinder 2 that are fixedly connected. The cylinder body 1 is provided with a spiral convex strip 12. A drill bit 13 is fixedly installed at the bottom end of the body 1. The drill bit 13 is a hollow structure, which is beneficial to reduce the overall weight of the sampling drill. The cylinder body 1 is provided with a feeding port 11, and a closure member 3 is installed in the cylinder body 1. The closure member 3 includes The transmission rod 31 and the sealing plate 32 are fixedly connected. After the sealing plate 32 is opened, the aggregate can enter the cylinder 1 along the feeding port 11. After the sealing plate 32 closes the feedin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap