Humidity control device, temperature control system of humidity control device and photolithography cabinet

A temperature control system and humidity control technology, which is applied to the exposure device of photoengraving process, air conditioning system, opto-mechanical equipment, etc. rate, to ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

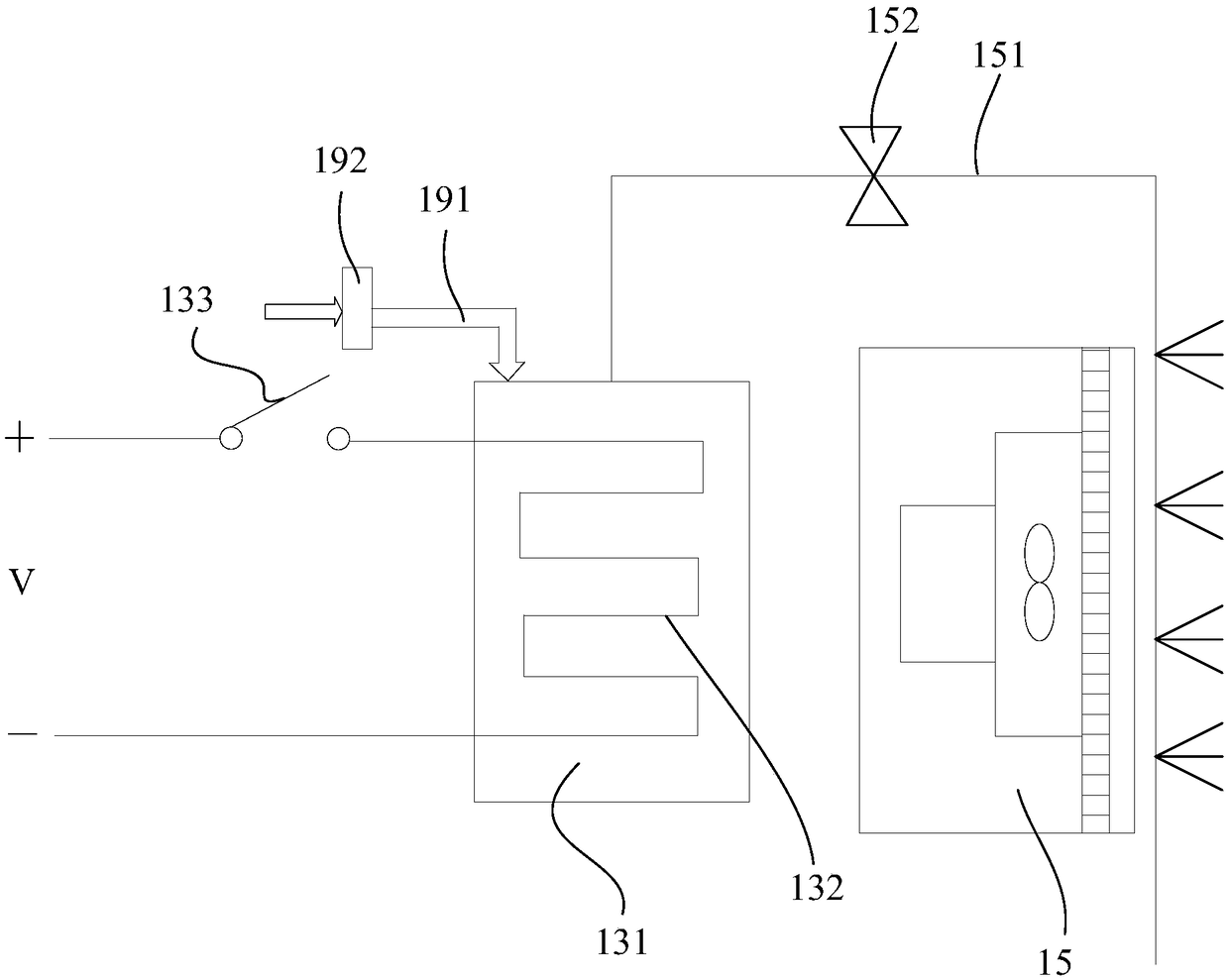

Embodiment Construction

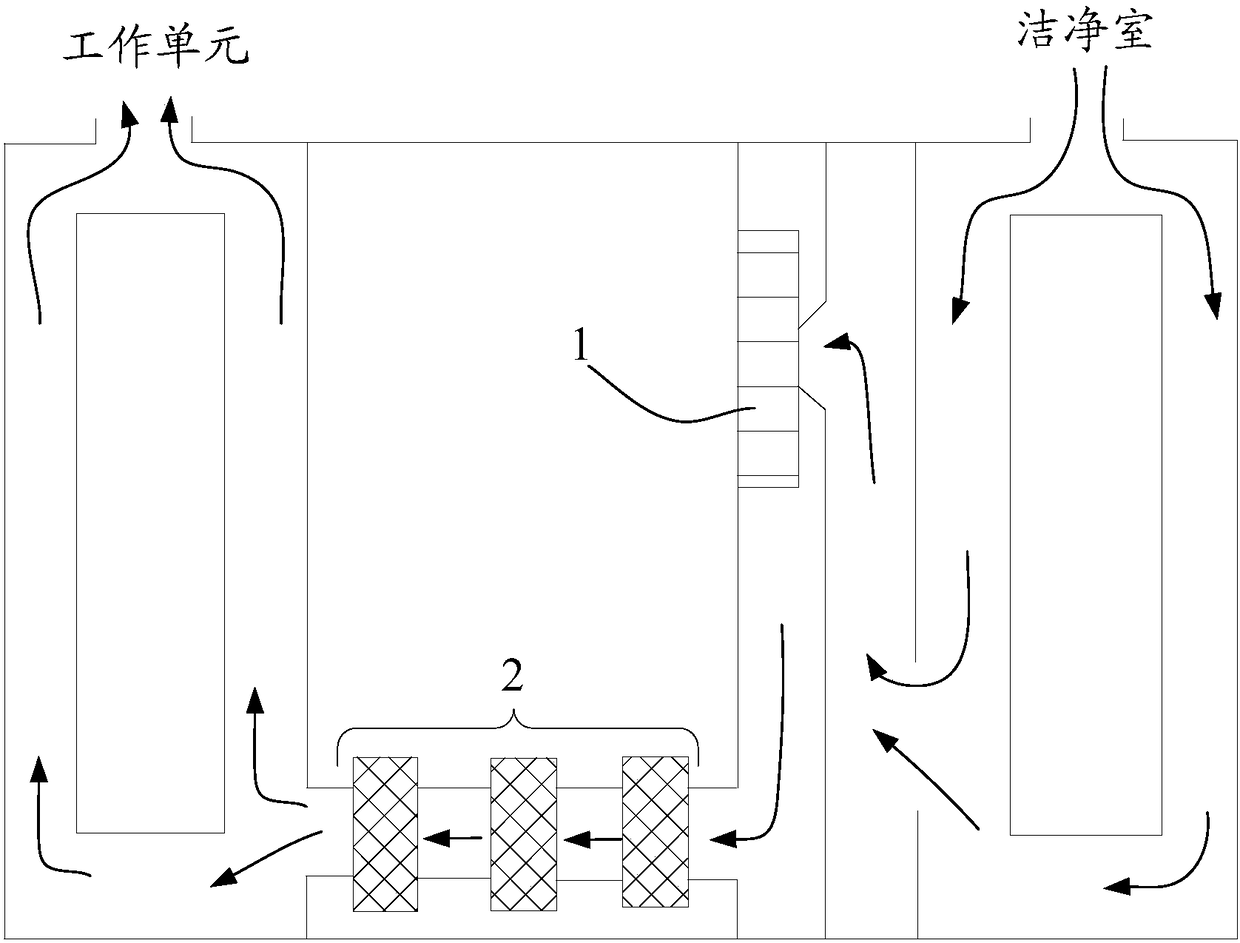

[0041] The humidity control device, its temperature control system, and the photolithography machine proposed by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. The advantages and features of the present invention will become clearer from the following description. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0042] As used in this specification, the singular forms "a", "an" and "the" include plural referents unless the content clearly dictates otherwise. As used in this specification, the term "or" is generally employed in its sense including "and / or" unless the content clearly dictates otherwise.

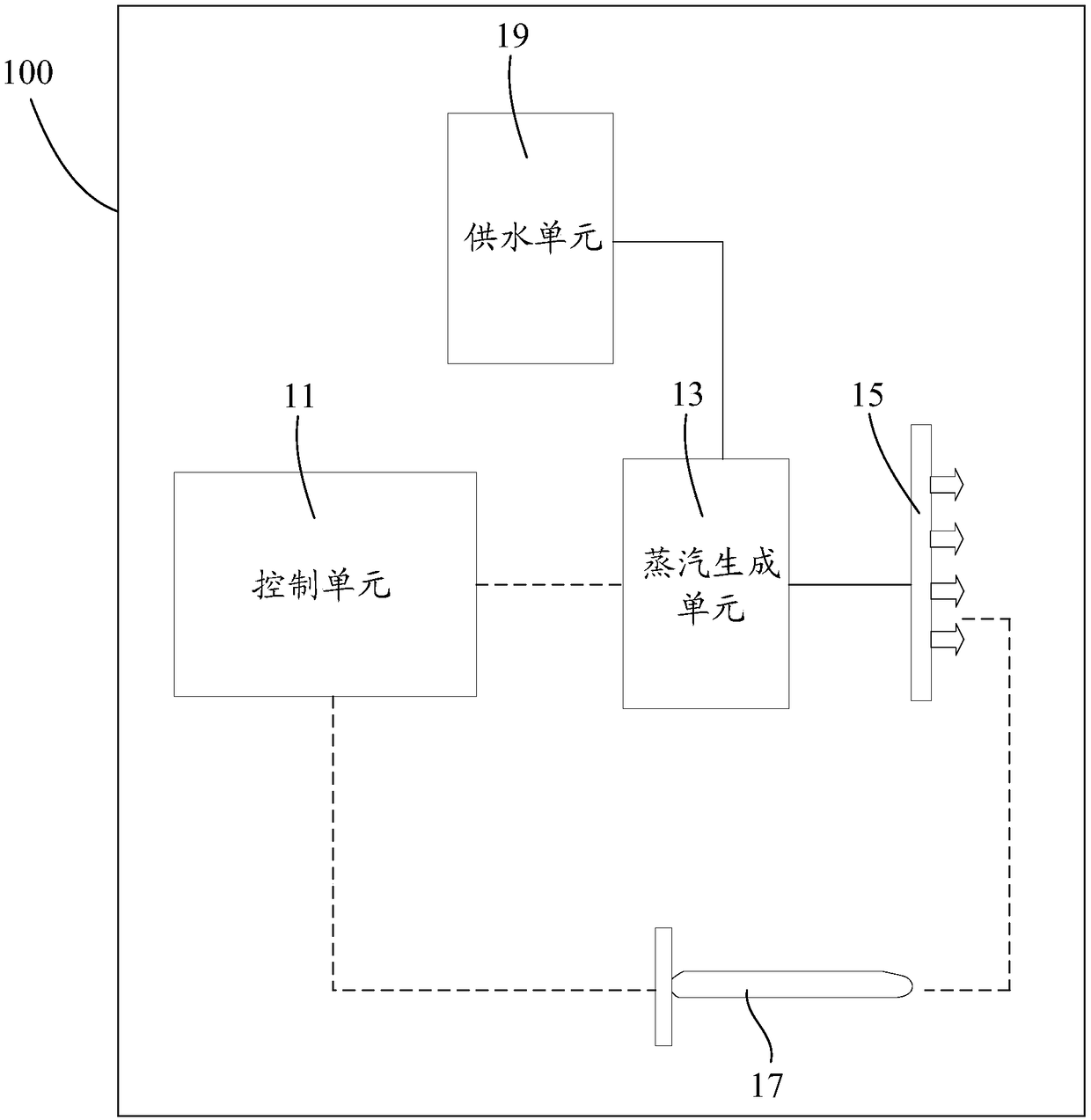

[0043] figure 2 The structural block diagram of the humidity control device provided for an embodiment of the present in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap