Clamping and hanging device for wing plate variable cross-section beam suspension

A technology of variable cross-section beams and wing plates, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as danger, precision-rolled threaded steel breakage, etc., and achieve convenient dismantling, local stress reduction, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

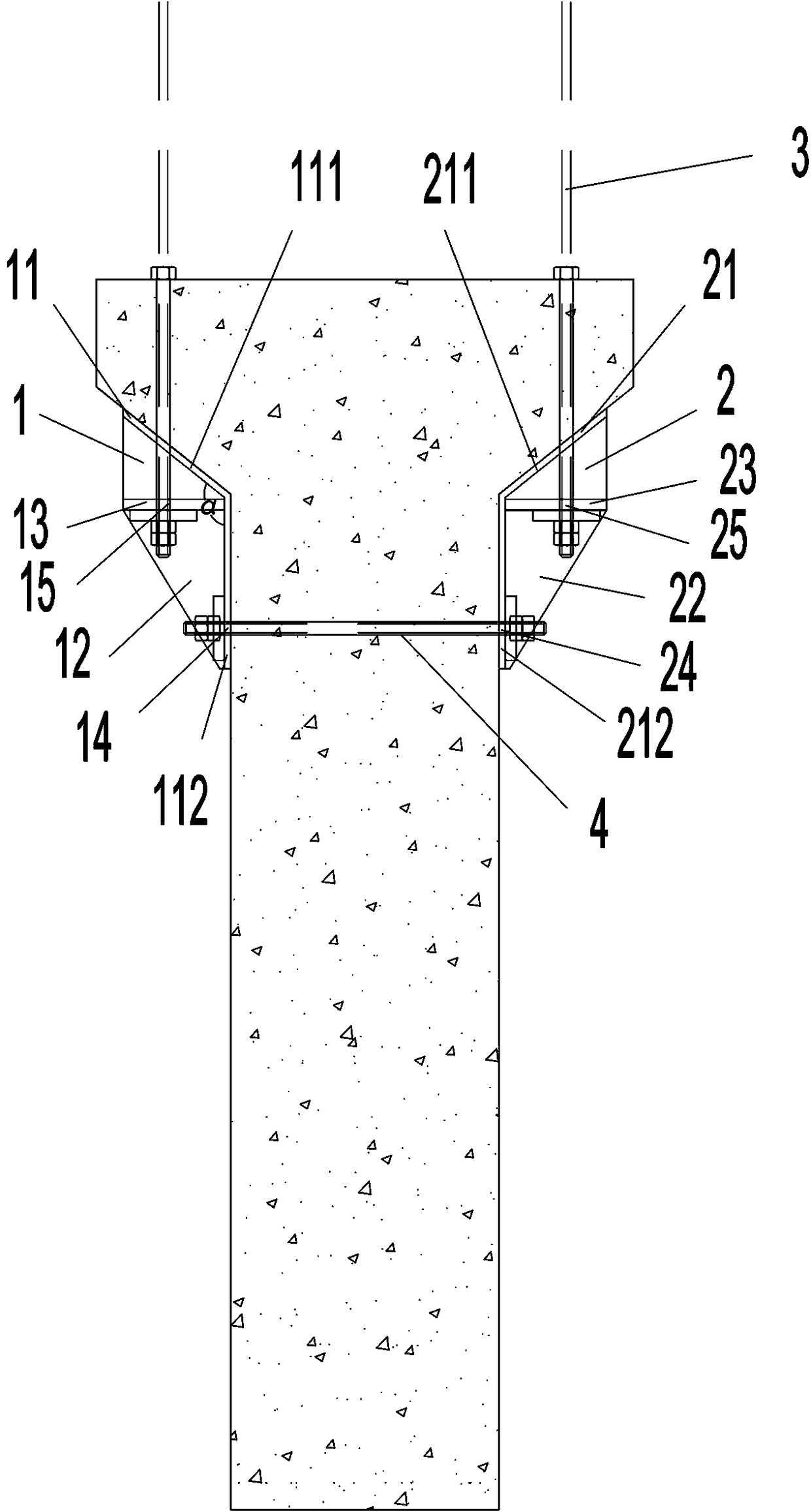

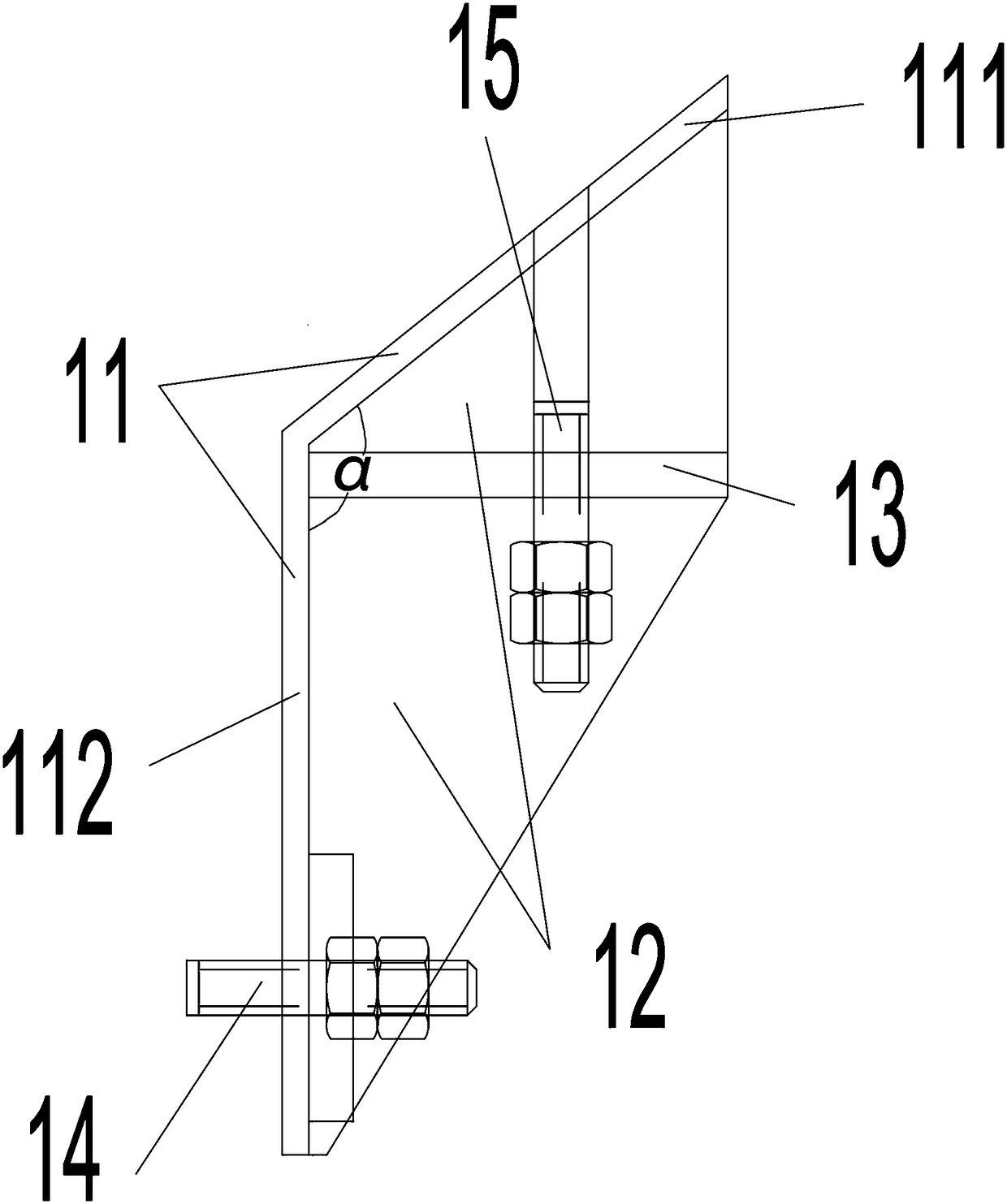

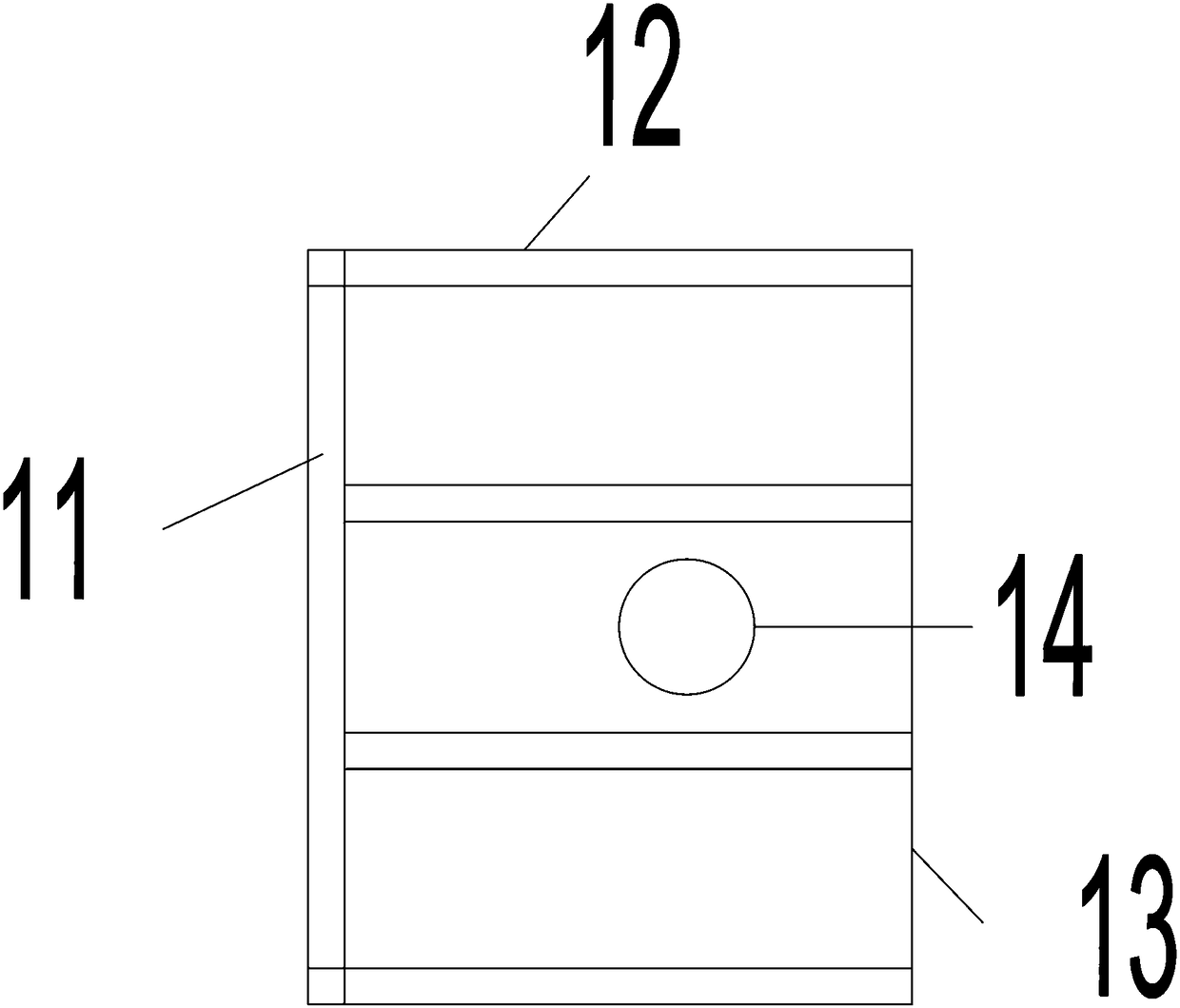

[0038] Such as figure 1 , 2 , 3 and 4, a clamping device for hanging a variable-section beam of a wing plate, is characterized in that: it includes a left clamping device 1 and a right clamping device 2 symmetrically placed on both sides of the turning point of the beam wing plate, and the left clamping device 2 The clamping and lifting device 1 includes a left sticking plate 11, a plurality of left ribs 12, a left support plate 13, a left reserved horizontal hole 14 and a left reserved vertical hole 15; the left sticking plate 11 includes at least two Composed of the first patch 111 and the second patch 112 at the corner, the angle α is greater than or equal to the turning angle of the beam wing, and the connection between the first patch 111 and the second patch 112 is fixed or integrated The left support plate 13 is molded, and the left support plate 13 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap