Storey-adding structure and method of steel structure building

A technology for adding layers of structures and steel structures, which is applied in building construction, construction, building maintenance, etc. It can solve problems such as long construction period, labor costs, crane shift costs, and component damage, so as to save machinery shift costs and speed up construction. The effect of high progress and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

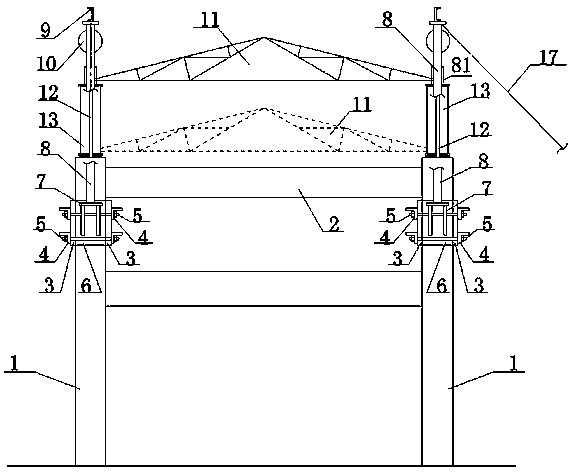

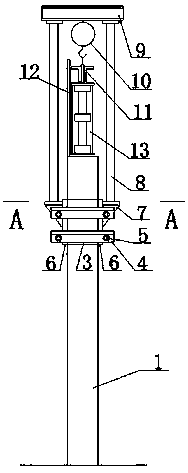

[0042] figure 1 It is a structural schematic diagram of the overall lifting process of the steel roof truss in this embodiment. In this embodiment, there are only horizontal pipe frame beams 12 at the top of the pipe frame column 1 and no longitudinal pipe frame beams 14 .

[0043] The steel structure building of this embodiment is a pipe gallery, and the layer-added structure of the pipe gallery includes pipe frame columns 1, support components, lifting columns 8, lifting beams 9, electric hoists 10, steel roof trusses 11, steel scale rods 12, and steel columns 13 .

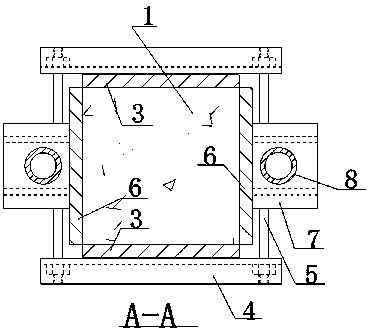

[0044] Such as Figure 1 to Figure 3As shown, the support components include front and rear hoops 3, side hoops 6, bolts 5, angle steel 4, and steel corbels 7. The two front and rear hoops 3 are respectively attached to the front and rear surfaces of the top of the pipe frame column 1. Two angle steels 4 are welded horizontally on the outer sides of the front and rear hoops 3, and the front and rear opposite pai

Embodiment 2

[0061] Figure 6 to Figure 8 It is a structural schematic diagram of the overall lifting process of the steel roof truss in this embodiment.

[0062] The difference from Embodiment 1 is that there is a longitudinal pipe frame beam 14 on the top of the pipe frame column 1 of this embodiment. In this embodiment, the steel plate 16 is used to support the lifting column 8 . The supporting parts of the lifting column 8 in this embodiment include anchor bolts 15 and steel plates 16. The top surfaces of the longitudinal pipe frame beams 14 close to the two sides of the pipe frame column 1 are planted with anchor bolts 15, and the steel plates 16 are fastened to the beam through the anchor bolts 15. 14 top surface, the lifting column 8 is welded on the steel plate 16.

[0063] When there are pre-embedded steel plates on the top surface of the original longitudinal pipe frame beam, the step of installing the steel plates 16 can be omitted, and the lifting column 8 is directly welded on

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap