Composite plastic woven bag capable of retaining freshness

A composite plastic, woven bag technology, applied in the direction of bags, sacks, climate sustainability, etc., can solve problems such as damage to food quality, and achieve the effect of preventing moisture resurgence, improving storage time, and facilitating long-term storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

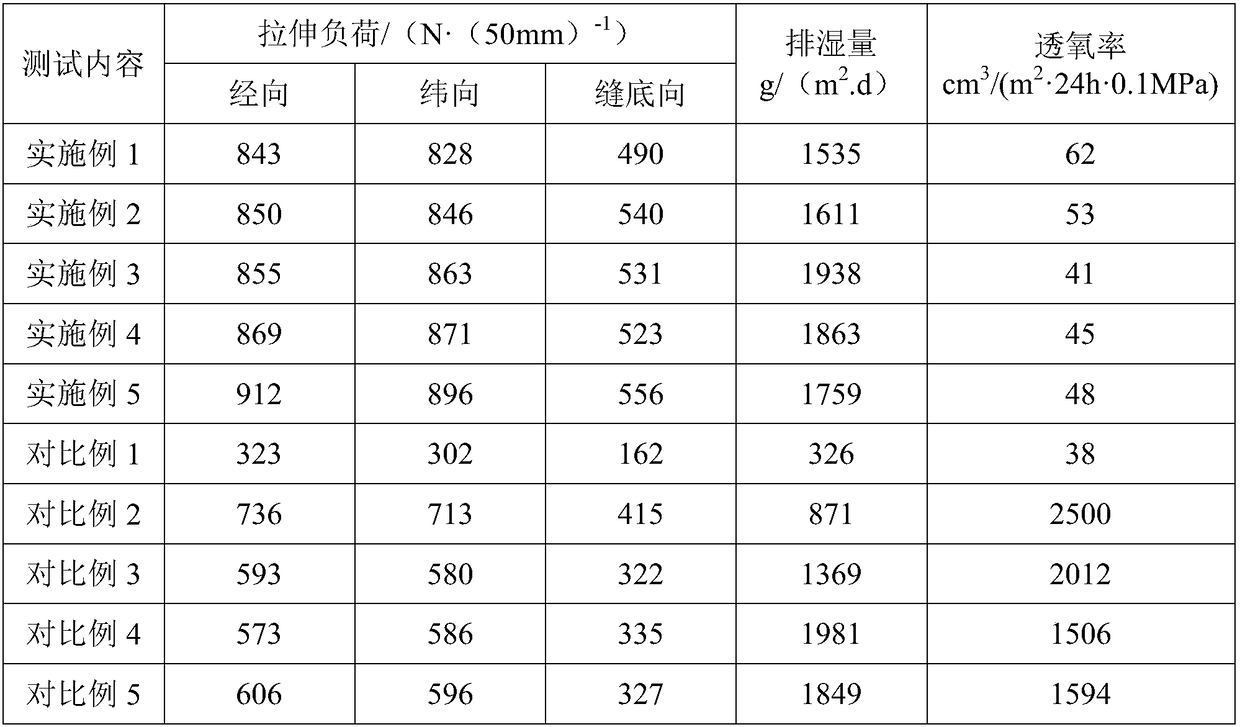

Examples

Embodiment 1

[0031] A fresh-keeping composite plastic woven bag comprises a water-absorbing layer, a braided layer and a protective layer from the inside to the outside;

[0032] The water-absorbing layer includes the following raw materials in weight percent: 55 parts of polyurethane pellets, 20 parts of polyethylene, 7 parts of loofah fiber, 0.5 part of coupling agent, 0.5 part of anti-aging agent, 0.5 part of antioxidant, chlorinated polyethylene 0.1 part; the loofah fiber is pretreated by mercerizing with dilute alkali solution. The thickness of the water-absorbing layer is 30 μm.

[0033] The braided layer includes the following raw materials in weight percentage: 60 parts of polypropylene pellets, 20 parts of polyethylene, 5 parts of coolmax fiber, 0.5 part of coupling agent, 0.5 part of anti-aging agent, 0.5 part of antioxidant, chlorinated polyethylene 0.1 part. The thickness of the braided layer is 0.1mm.

[0034] The protective layer includes the following raw materials in weight

Embodiment 2

[0036] A fresh-keeping composite plastic woven bag comprises a water-absorbing layer, a braided layer and a protective layer from the inside to the outside;

[0037] The water-absorbing layer includes the following raw materials in weight percent: 60 parts of polyurethane pellets, 22 parts of polyethylene, 9 parts of loofah fiber, 1 part of coupling agent, 0.8 part of anti-aging agent, 1 part of antioxidant, chlorinated polyethylene 0.2 part; the loofah fiber is pretreated by mercerizing with dilute alkali solution. The thickness of the water-absorbing layer is 45 μm.

[0038] The braided layer includes the following raw materials in weight percentage: 62 parts of polypropylene pellets, 22 parts of polyethylene, 7 parts of coolmax fiber, 1 part of coupling agent, 0.8 part of anti-aging agent, 1 part of antioxidant, chlorinated polyethylene 0.2 part; the thickness of the braided layer is 0.2mm.

[0039] The protective layer includes the following raw materials in weight percenta

Embodiment 3

[0041] A fresh-keeping composite plastic woven bag comprises a water-absorbing layer, a braided layer and a protective layer from the inside to the outside;

[0042] The water-absorbing layer includes the following raw materials in weight percent: 65 parts of polyurethane pellets, 25 parts of polyethylene, 10 parts of loofah fiber, 1.5 parts of coupling agent, 1.2 parts of anti-aging agent, 1.5 parts of antioxidant, chlorinated polyethylene 0.3 part; the loofah fiber is pretreated by mercerizing with dilute alkali solution. The thickness of the water-absorbing layer is 60 μm.

[0043] The braided layer includes the following raw materials in weight percentage: 65 parts of polypropylene pellets, 25 parts of polyethylene, 8 parts of coolmax fiber, 1.5 parts of coupling agent, 1.2 parts of anti-aging agent, 1.5 parts of antioxidant, chlorinated polyethylene 0.3 parts; the thickness of the braided layer is 0.25mm.

[0044] The protective layer includes the following raw materials i

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap