Water meter shell body forging and pressing die

A water meter and shell technology, which is applied in forging presses, forging presses, forging/pressing/hammer devices, etc., can solve the problem that the water outlet of the water meter shell cannot be formed by punching through holes at one time, the design of the mold opening structure is difficult, and the mold structure design is difficult. Difficulty and other problems, to achieve the effect of solving the problem of mold opening and taking parts, ingenious mold structure design, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

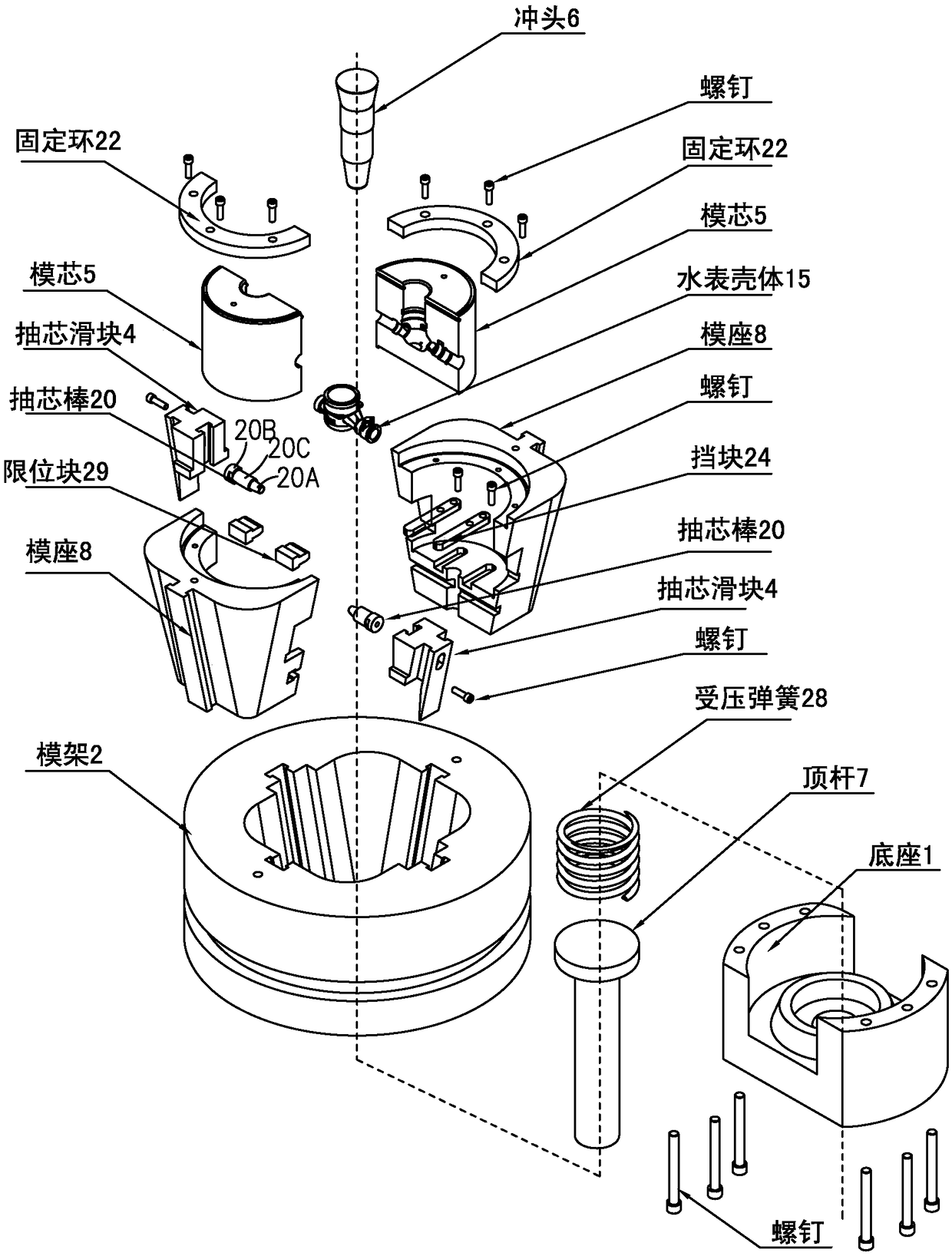

[0028] the following to Figure 1 to Figure 9 As shown, the specific implementation manner of the preferred embodiment of the present invention is described.

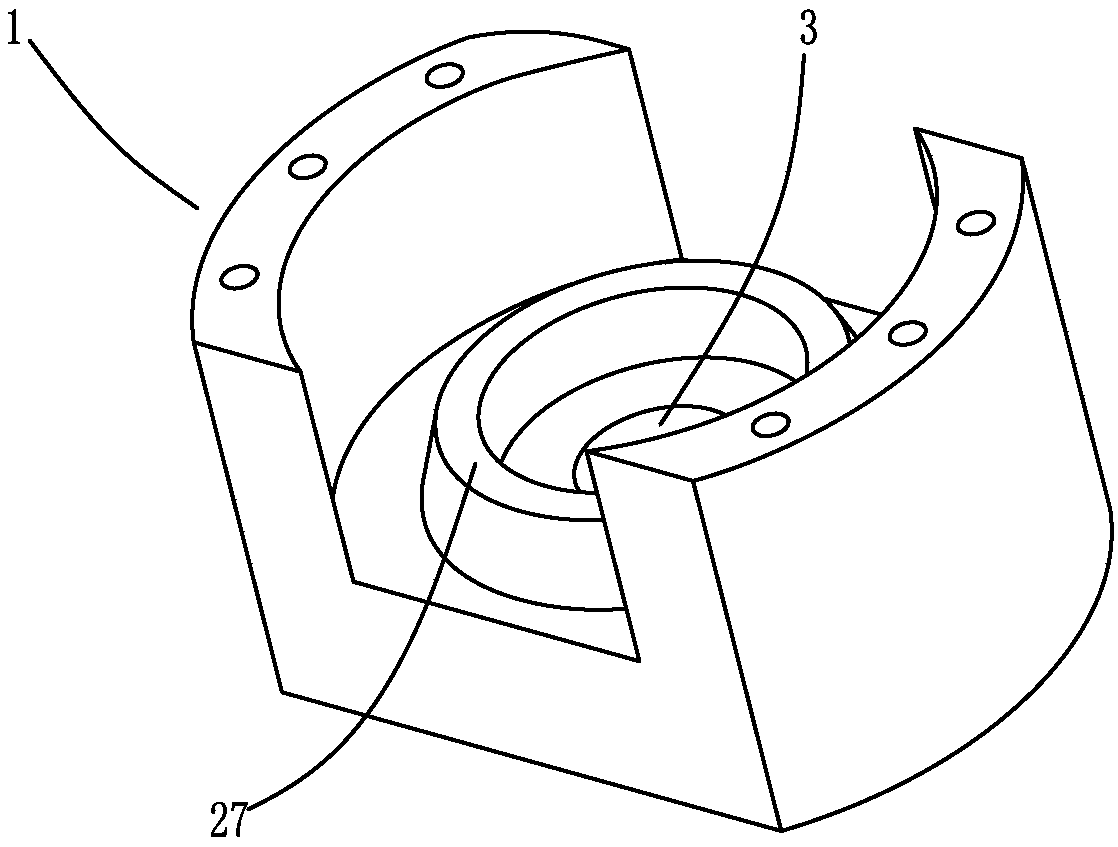

[0029] A water meter casing 15 forging mold, used for one-time forging and forming of the water meter casing 15; figure 1 As shown, the forging die includes a base 1, a disc-shaped mold base 2 fixedly installed on the base 1, and a bottom hole 3 is opened in the middle of the base 1; it also includes a mold base 8 and core-pulling sliders 4 on both sides, and a mold core 5. Punch 6 and ejector pin 7.

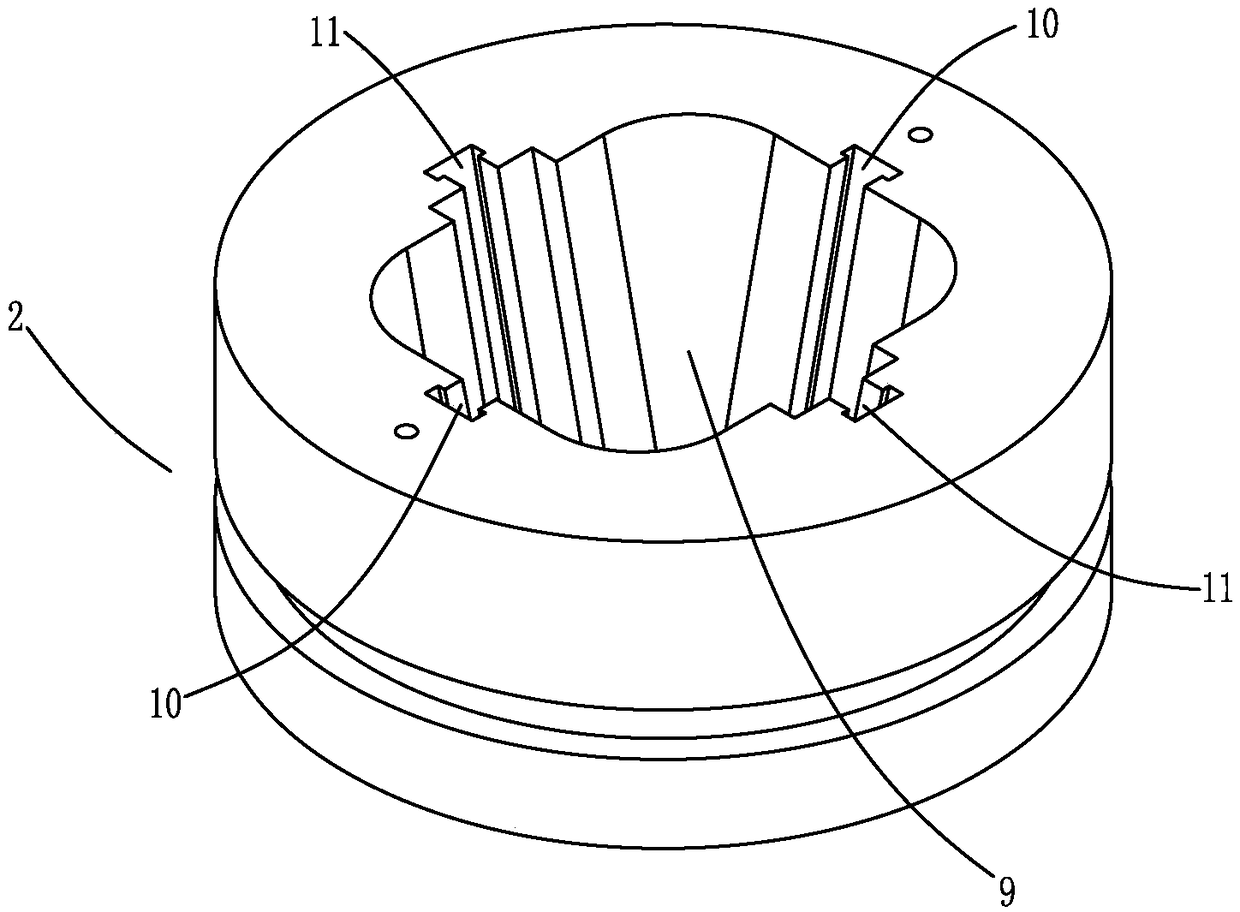

[0030] Such as figure 1 , figure 2 As shown, the center of the mold base 2 is provided with a through-cavity 9 for accommodating the mold base 8. The mold base 2 runs through the cavity 9 and the mold base 8 matched with it forms a rectangle with four-corner arc transitions on the horizontal plane. Its side wall is an inclined wall, and the relatively inclined walls around the cavity 9 of the formwork 2 are respectively

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap