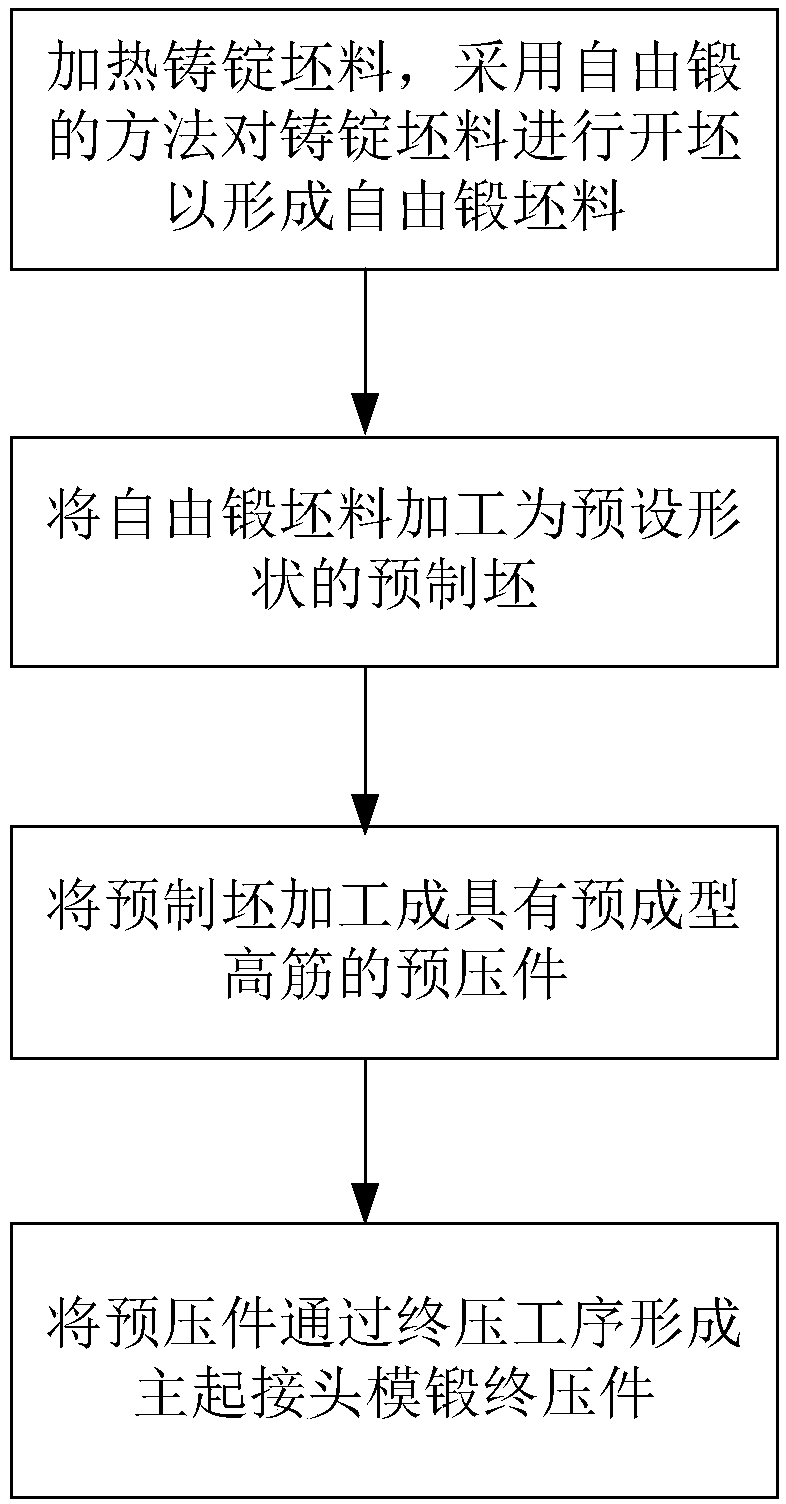

Die forging process method of main starting connector of airplane

A process method and die forging technology, applied in the direction of manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of unsatisfactory filling, flow through, and folding at high ribs, achieve uniform deformation structure, and avoid filling. The effect of dissatisfaction and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In view of this, the core of the present invention is to provide a die forging process for the main lifting joint of the aircraft, which can effectively avoid the phenomenon of insufficient filling, folding, and flow-through at the high ribs of the main starting joint, thereby obtaining high dimensional accuracy and uniform deformation structure die forgings.

[0027] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The die forging process method for the main lifting joint of the aircraft disclosed in the embodiment of the present invention includes: 1) heating the ingot blank 1, and adopting the free forging method to open the rotary blank 1 to form the free forging blank 2; 2) forming the free forging blank 2; The blank 2 is processed into a preform 3 of a predetermined shap

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap