A shock absorber for automobile seats

A technology of shock absorbing device and car seat, which is applied in the direction of seat suspension device, etc., can solve the problems that the shock absorbing device is not suitable for large-scale popularization and application, the shock absorbing effect is general, and the structure is complicated, and the shock absorbing effect is obvious, Guaranteed shock absorption effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

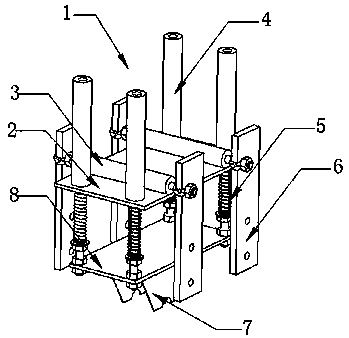

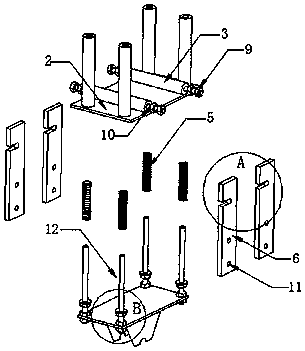

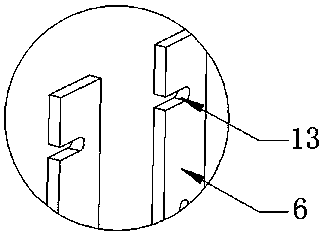

[0020] Such as Figure 1 to Figure 5 As shown, the shock absorbing device 1 includes a support plate 2 arranged horizontally, a support column 4 is provided above the four corners of the support plate 2, and two fixed cylinders 3 are arranged on the inner side of the support column 4. Both ends of the cylinder 3 are provided with a screw rod 10, and one end of each screw rod 10 is clamped with a baffle plate 6, and the upper part of each baffle plate 6 is provided with a bayonet 13, and the side of the baffle plate 6 is provided with several Round hole 11, a base device 12 is installed below the support plate 2, a base plate 8 is installed on the bo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap