New multi-kettle switching-type waste heat mutually-utilizing waste, sludge and fecal material pyrolysis equipment

A switchable, waste heat technology, applied in lighting and heating equipment, combustion methods, combustion types, etc., can solve the problems of difficult pyrolysis of garbage, sludge, difficulty of pyrolysis or incineration, and little use of heat energy, etc., to achieve full utilization Thermal energy, saving space and investment, novel structure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0016] The present invention will be further described in conjunction with the following examples.

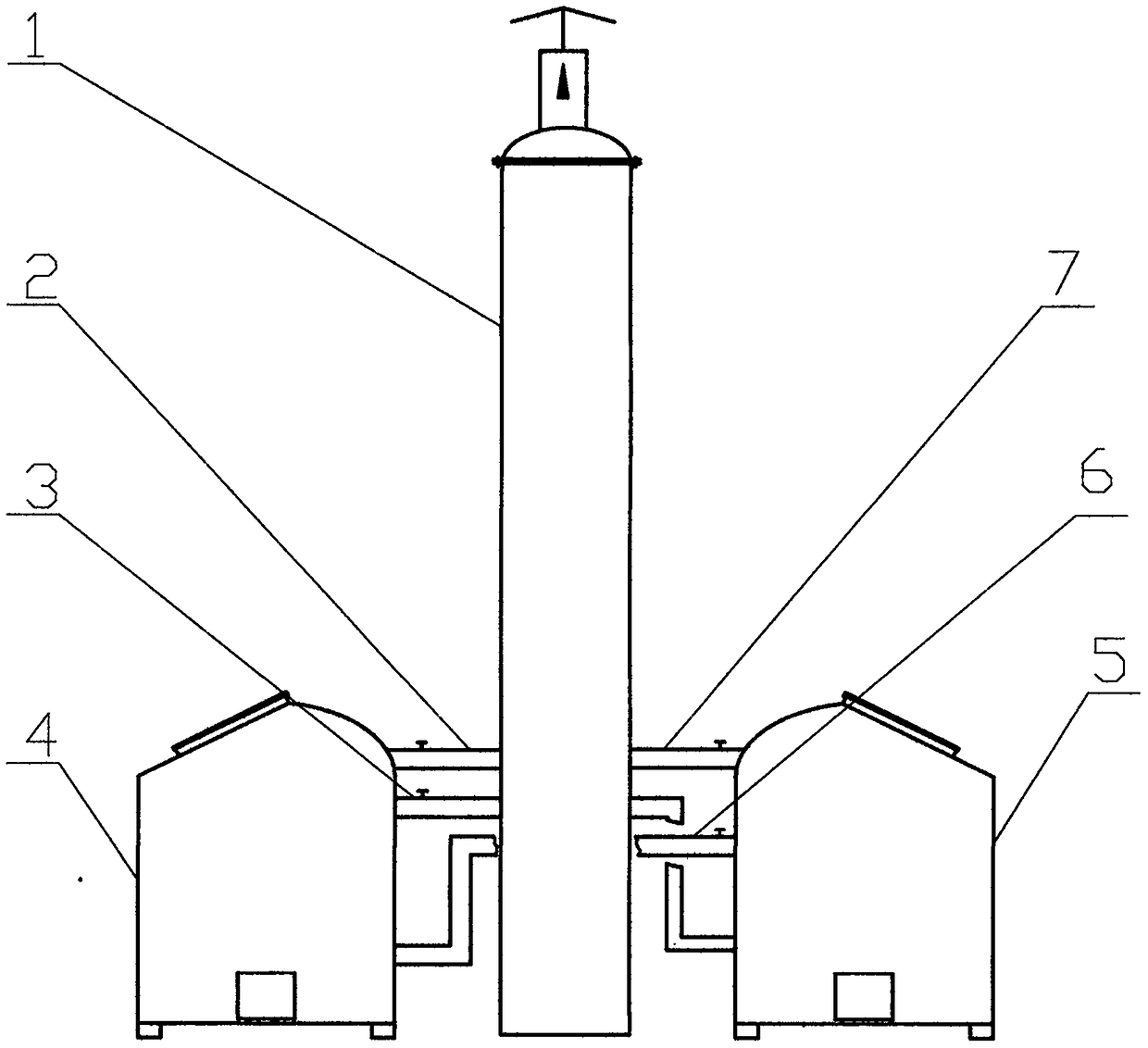

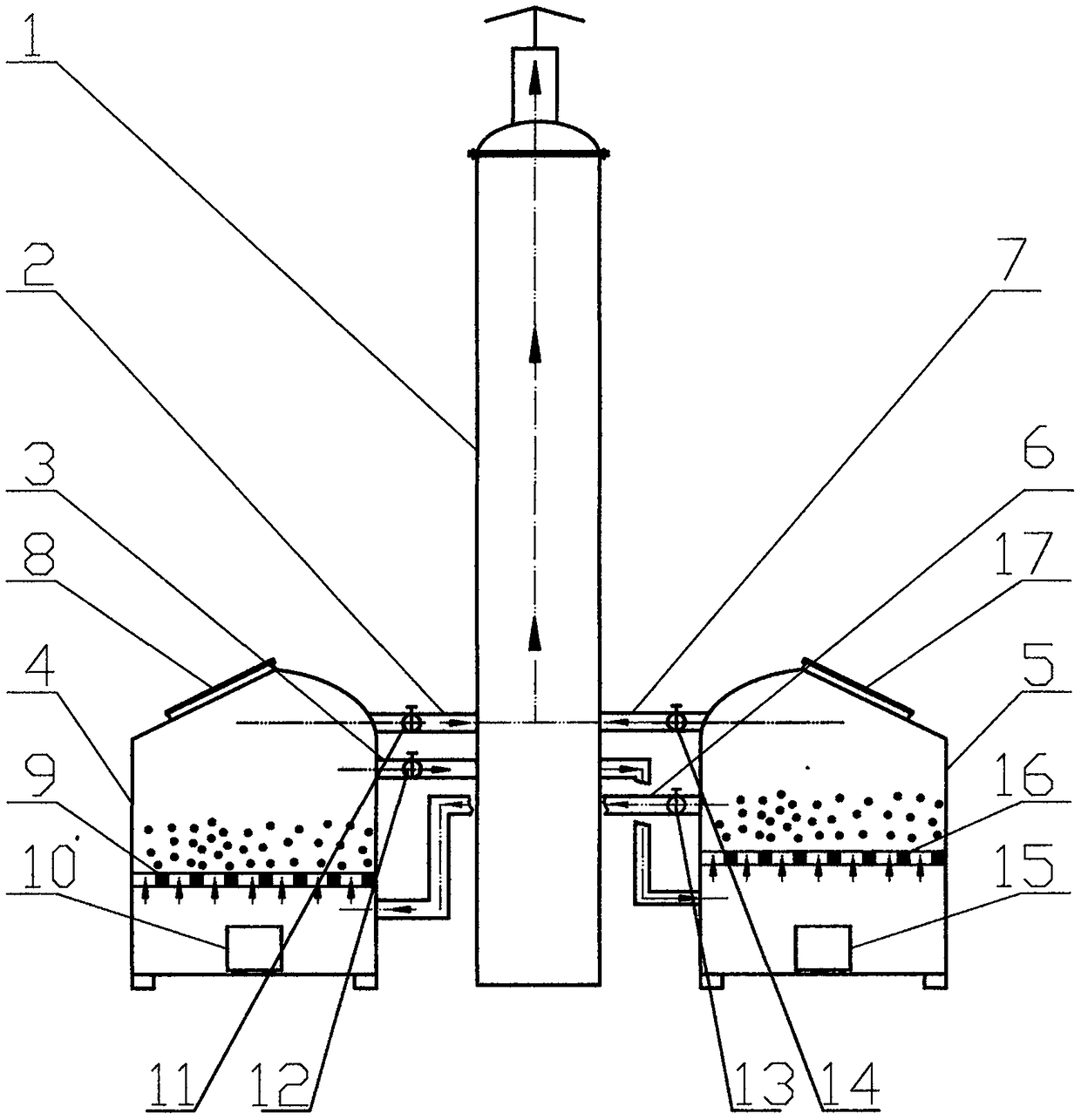

[0017] A new equipment for pyrolyzing garbage, sludge and manure by using multi-kettle switching waste heat, consisting of tail gas purification tower 1, left connecting pipe 2, left high temperature gas pipe 3, left pyrolysis furnace 4, right pyrolysis furnace 5, and right high temperature gas pipe 6. The right connecting pipe 7 is composed of, in which the left side of the tail gas purification tower 1 is connected and communicated with the left pyrolysis furnace 4 through the left connecting pipe 2 and the left pyrolysis furnace 4 is connected and communicated through the left high temperature gas pipe 3; the tail gas purification tower 1 The right side is connected and communicated with the right pyrolysis furnace 5 through the right connecting pipe 7, and is connected and communicated with the right pyrolysis furnace 5 through the right high-temperature gas pipe 6.

[0018] The le

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap