Rubberized textile material for a belt ply, associated rubber mixture and belt

A technology of rubber mixture and textile materials, which is applied in the direction of textiles and papermaking, applications, clothing belts, etc., can solve the problems of poor strength and hardness, achieve the effects of simplifying the assembly process, saving glued materials, and improving machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

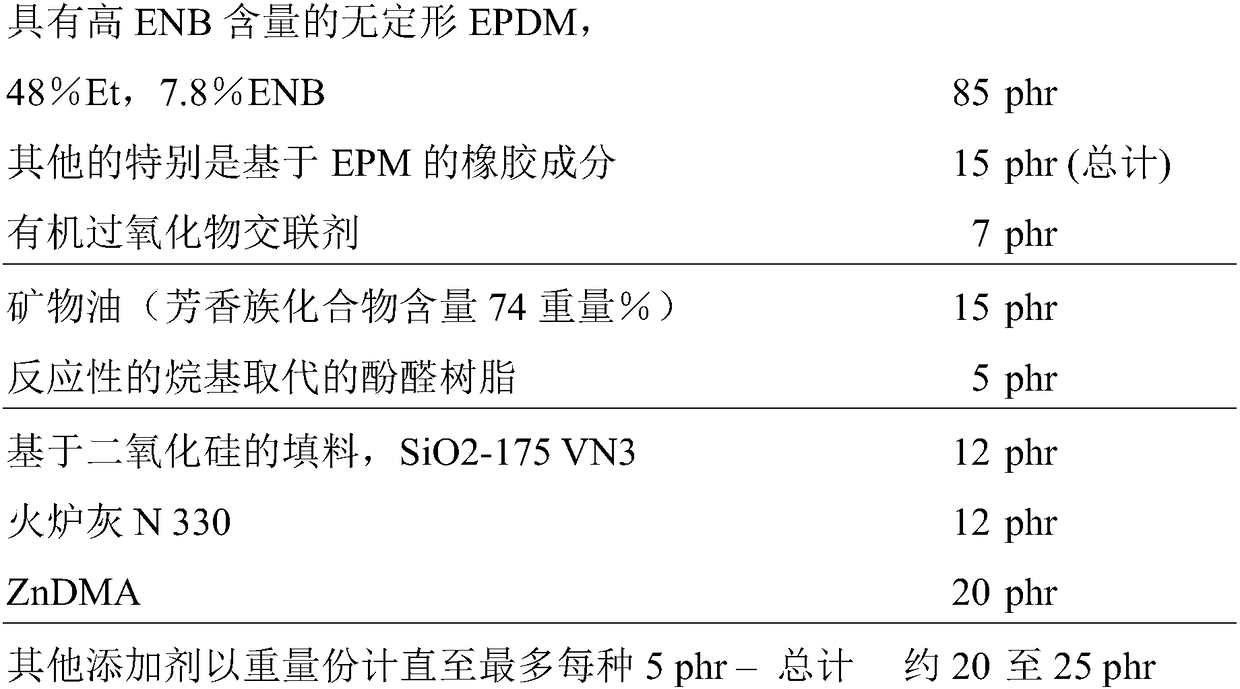

[0056] Example 1-Rubber mixture according to the invention:

[0057]

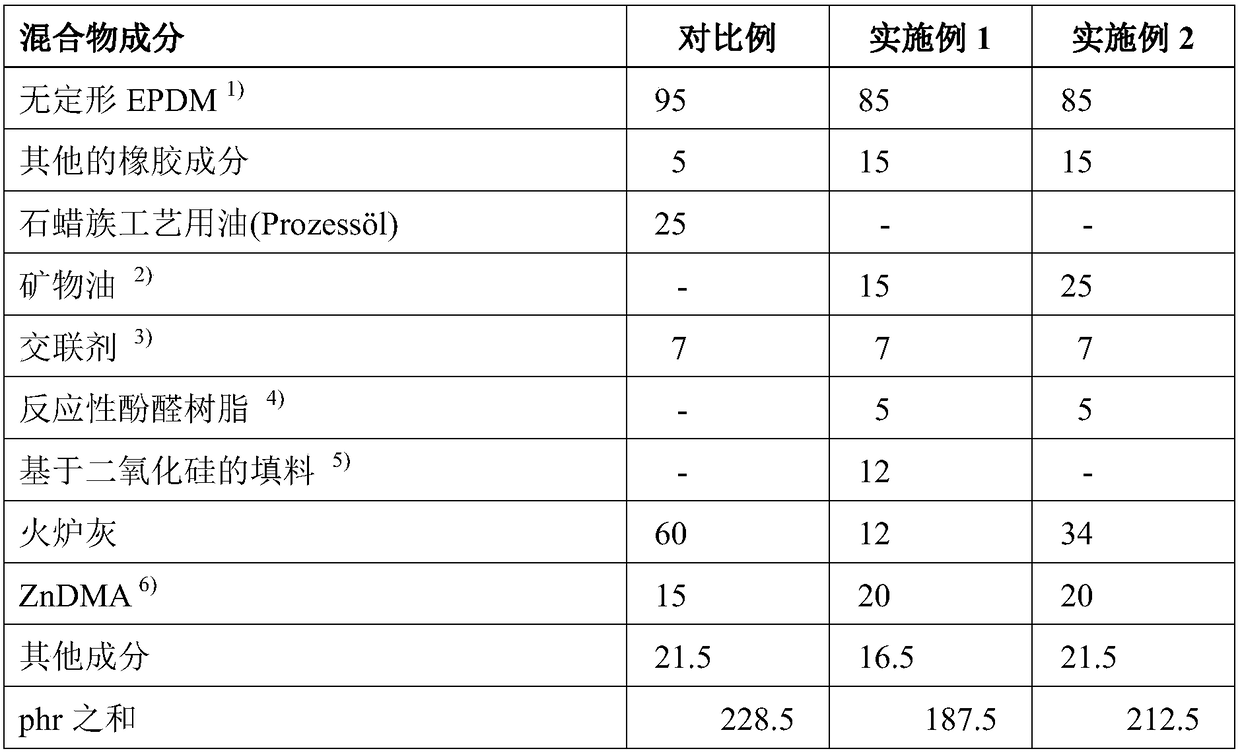

[0058] The first embodiment of the rubber mixture according to the present invention is used to coat textiles, so that the rubberized textile material thus obtained is used to prepare a belt with a rubberized textile layer, as shown in the following table with the rubber mixture according to the present invention. The second embodiment and the comparative example of the traditional glue mixture are compared.

[0059] Table 1 (numerical data in phr)

[0060]

[0061] 1) Amorphous EPDM with high ENG content, 48% Et, 7.8% ENB

[0062] 2) Mineral oil with 74% aromatic compound content

[0063] 3) Organic peroxide crosslinking agent

[0064] 4) Reactive alkyl substituted phenolic resin

[0065] 5) SiO2-175VN3

[0066] 6) Dynalink 634

[0067] Compared with the conventional (commercially available) EPDM rubber compound described in the "comparative example", the rubber compound according to the present invention can make the ass

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap