Application of ferrous-iron feeding liquid in aspect of promoting fermentation of bacterial groups for organic waste treatment

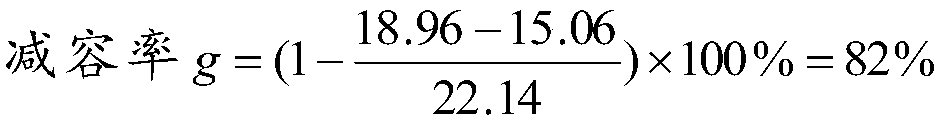

A technology for supplying liquid and ferrous iron, which is applied to fertilizers made of biological waste, applications, organic fertilizers, etc., can solve the problems of difficulty in organic waste, efficient disposal of waste, and inability to eliminate the odor of organic waste, etc. Achieve the effect of shortening the fermentation period, degrading organic phosphorus well, and improving the volume reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

[0022] The preparation of embodiment 1 ferrous iron supply liquid

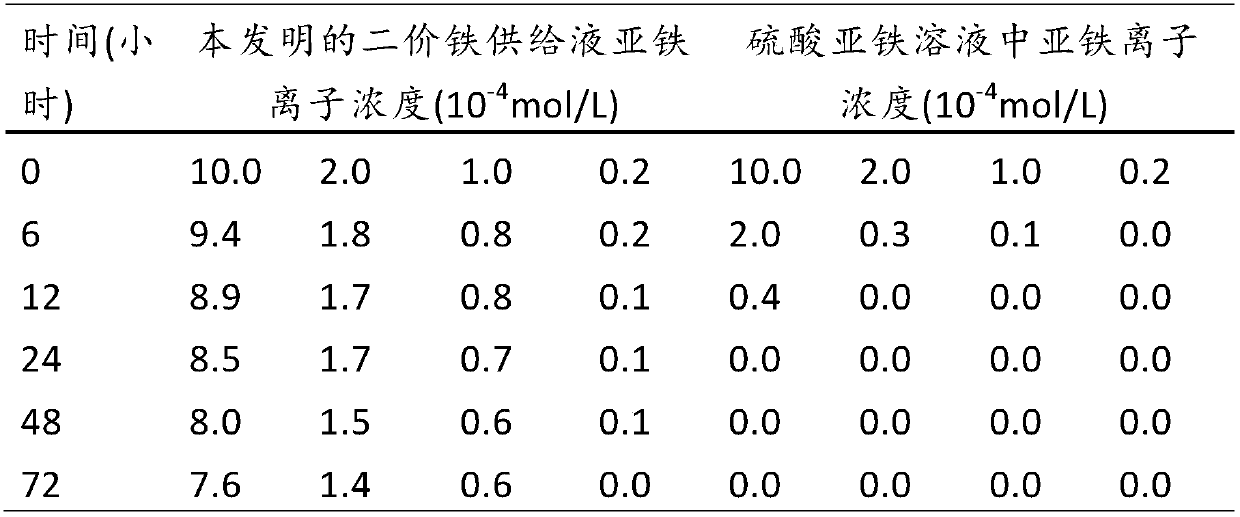

[0023] Put citric acid monohydrate powder (2.5mol) with a purity of ≥99% into a reactor with 10L of water, heat up to 60°C, and slowly add a total of 3mol of carbonic acid with a purity of ≥97% in 10 batches under stirring. Sodium, stir for 6 minutes after each batch is added and heat up to 80°C, use nitrogen to isolate the air, add 1 mol of ferrous sulfate heptahydrate with a purity of ≥95% at one time, finally heat up to 92°C, and keep stirring at 92°C to react 2 hours. Cool down to room temperature in the absence of air. Finally, a ferrous iron supply liquid is obtained.

[0024] After inspection, in the ferrous iron supply liquid of the present embodiment, the total concentration of ferrous ions (ferrous iron) in the mixed solution is 0.095mol / L, and the moles of ferrous sodium citrate, ferrous sulfate, and ferrous citrate The mass ratio is 1:0.28:0.23.

Embodiment 2 2

[0025] Embodiment 2 Preparation of ferrous iron supply liquid

[0026] Put citric acid monohydrate powder (2.5mol) with a purity of ≥99% into a reactor with 10L of water, heat up to 50°C, and slowly add a total of 3mol of carbonic acid with a purity of ≥97% in 8 batches under stirring. Sodium, after each batch is added, stir for 8 minutes and heat up to 70°C, use nitrogen to isolate the air, add 1 mol of ferrous sulfate heptahydrate with a purity of ≥95% at one time, finally heat up to 88°C, and keep stirring at 88°C for 5 Hour. Cool down to room temperature in the absence of air. Finally, a ferrous iron supply liquid is obtained.

[0027] After inspection, in the ferrous iron supply liquid of the present embodiment, the total concentration of ferrous ions (ferrous iron) in the mixed solution is 0.095mol / L, and the moles of ferrous sodium citrate, ferrous sulfate, and ferrous citrate The mass ratio is 1:0.38:0.17.

Embodiment 3 2

[0028] Embodiment 3 Preparation of ferrous iron supply liquid

[0029] Put citric acid monohydrate powder (2.5mol) with a purity of ≥99% into a reaction kettle with 10L of water, raise the temperature to 55°C, and slowly add a total of 3mol of sodium carbonate with a purity of ≥97% in 12 batches under stirring After each batch is added, stir for 4 minutes and raise the temperature to 75°C, use nitrogen to isolate the air, add 1 mol of ferrous sulfate heptahydrate with a purity of ≥95% at one time, and finally raise the temperature to 90°C, and keep stirring at 90°C for 2 Hour. Cool down to room temperature in the absence of air. Finally, a ferrous iron supply liquid is obtained.

[0030]After inspection, in the ferrous iron supply liquid of the present embodiment, the total concentration of ferrous ions (ferrous iron) in the mixed solution is 0.095mol / L, and the moles of ferrous sodium citrate, ferrous sulfate, and ferrous citrate The mass ratio is: 1:0.35:0.2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap