Glass tube forming numerical-control shaping machine with flowmeter

A glass tube and flowmeter technology, which is applied in the field of glass tube forming numerical control shaping machines, can solve the problems of inability to realize tubular glass forming and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

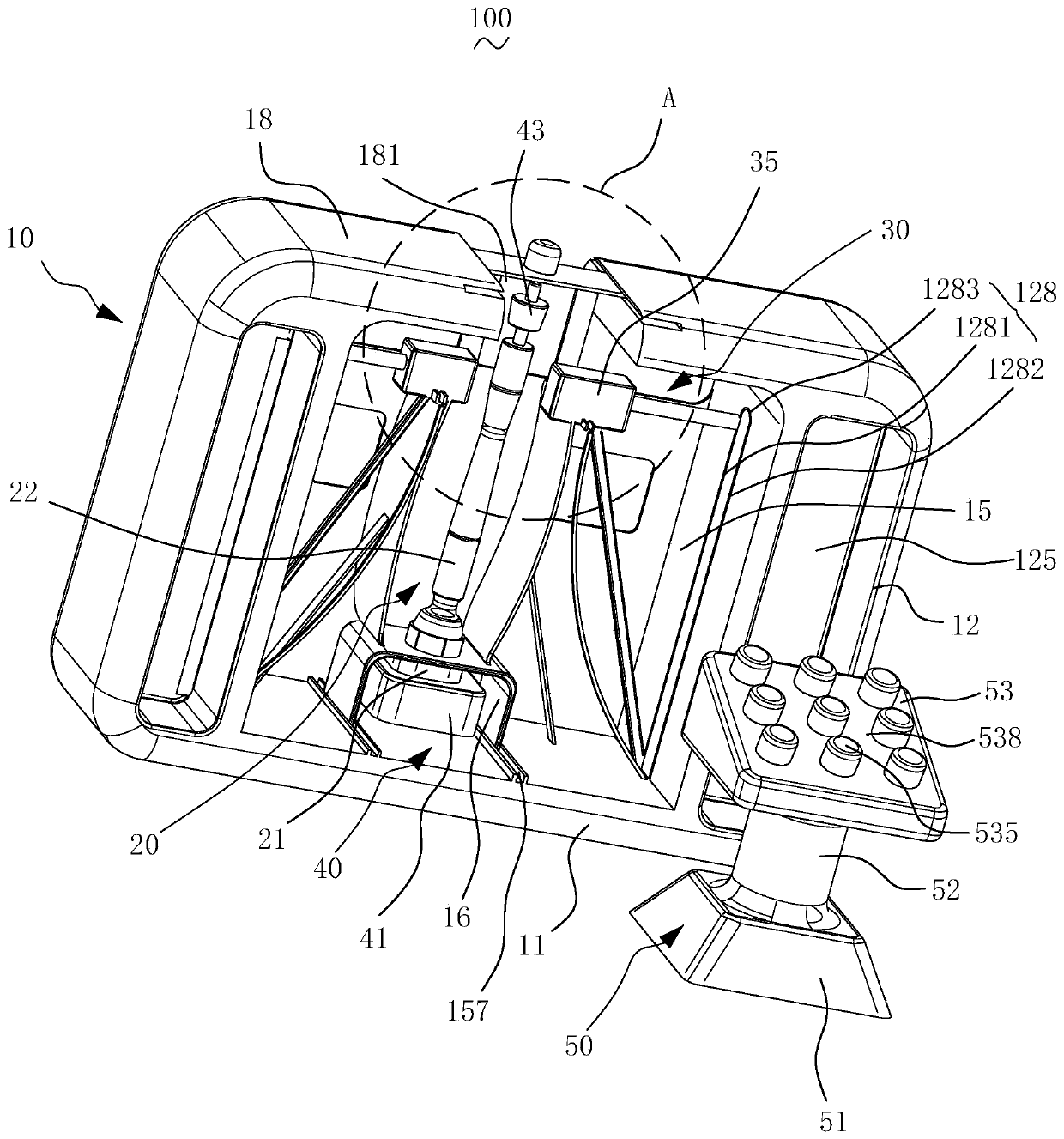

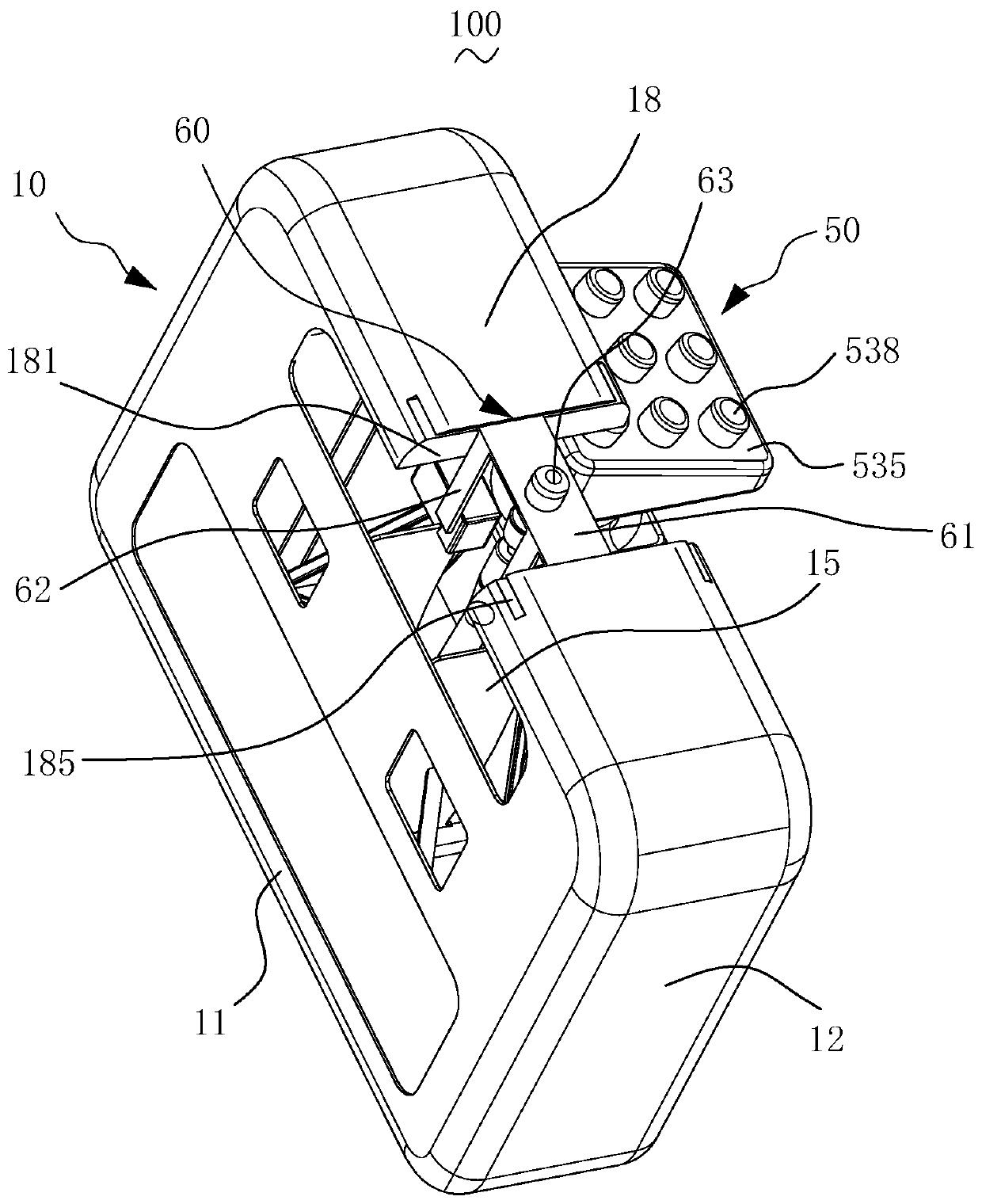

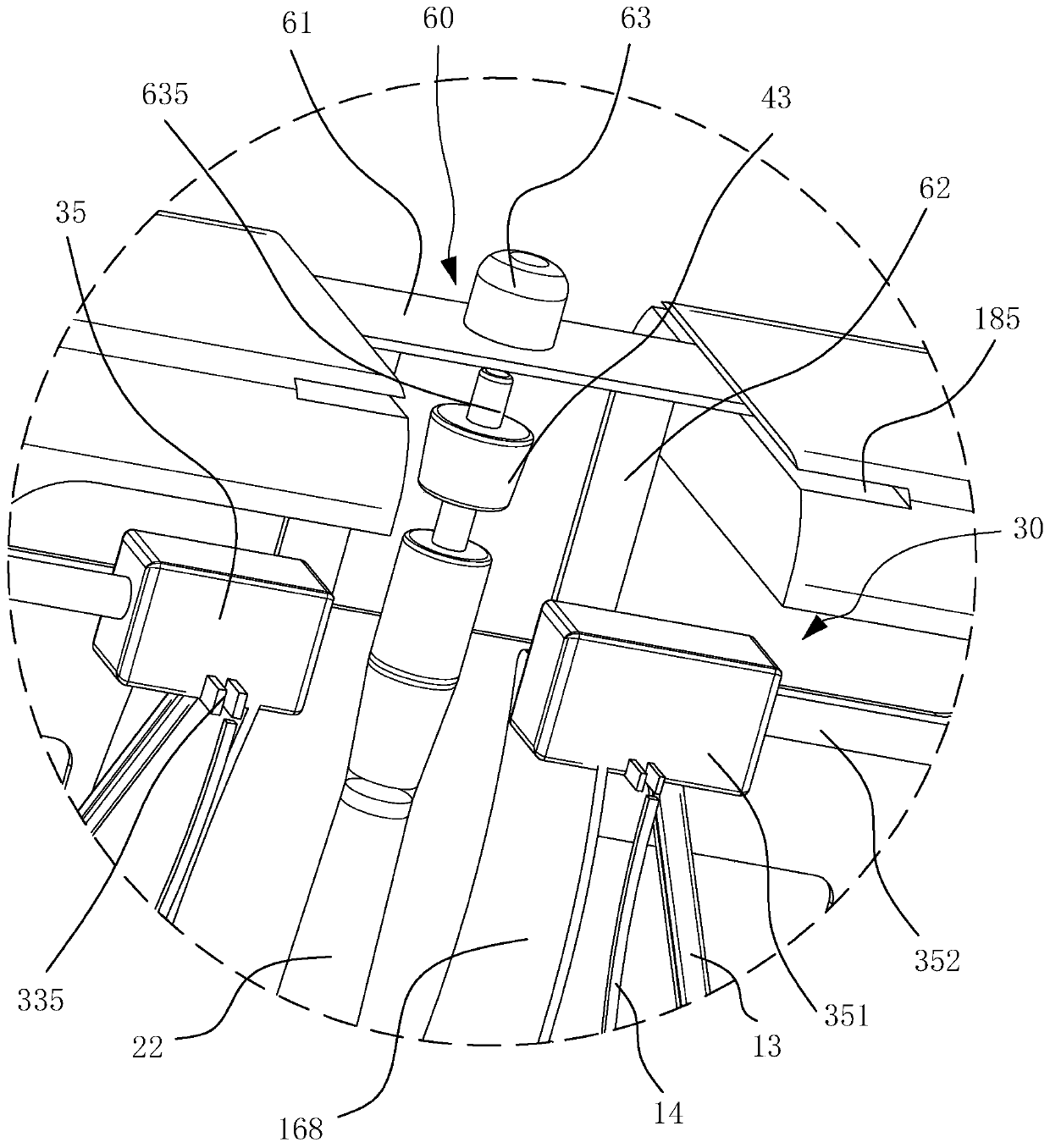

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] see figure 1 and figure 2 , a glass tube forming numerically controlled shaping machine 100 with a flowmeter, comprising a numerically controlled machine 10, a forming assembly 20, a heating assembly 30, a vacuum assembly 40, and a console 50, wherein a forming space 15 is formed in the numerically controlled machine 10, The molding assembly 20 includes a rotating drive member 21 and a rotating mandrel 22, the rotating driving member 21 is arranged at the bottom of the molding space 15, and the rotating mandrel 22 is installed on the rotating driving member 21 for The glass tube is sleeved and installed, and the heating assembly 30 is movably installed on the side wall of the molding space 15 for heating the glass tube. The vacuum assembly 40 is arranged adjacent to the rotary drive member 21 for When vacuuming the inside of the glass tube, the console

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap