Cutter forging device of numerical control milling machine

A technology of CNC milling machine and console, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of temperature reduction, inconsistent overall progress, inconsistent flame temperature to the highest point and range, etc., to achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

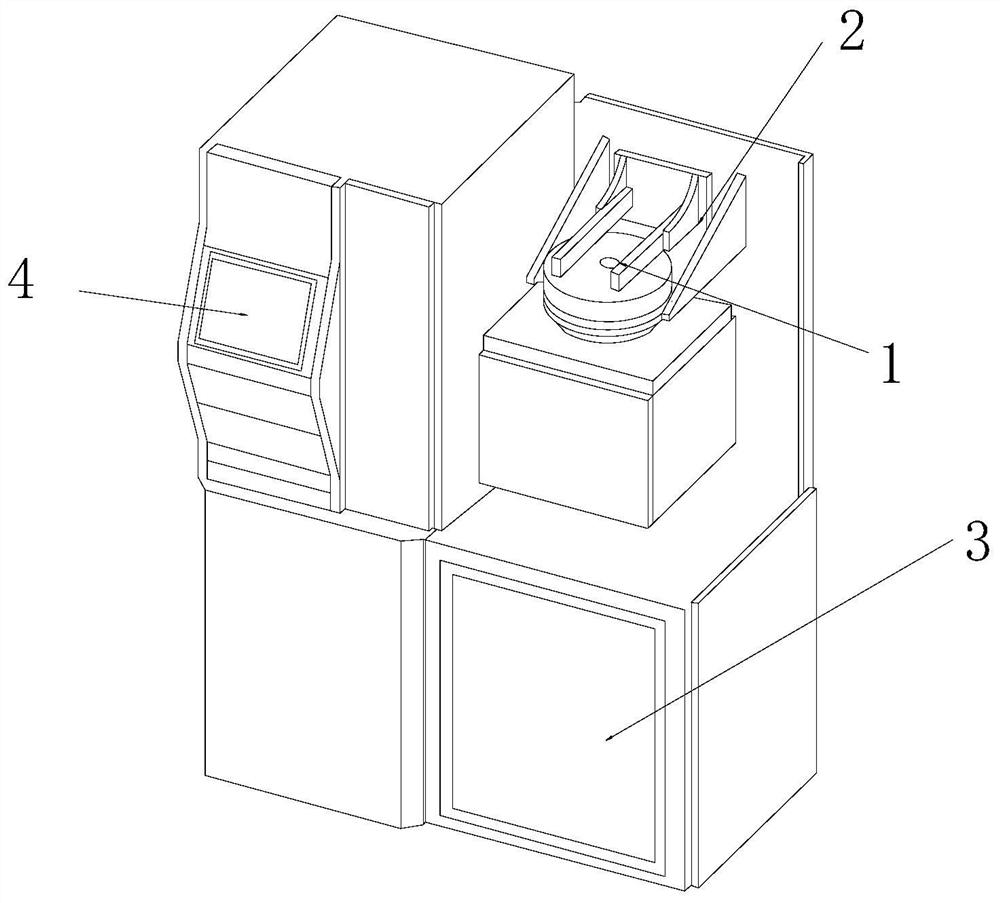

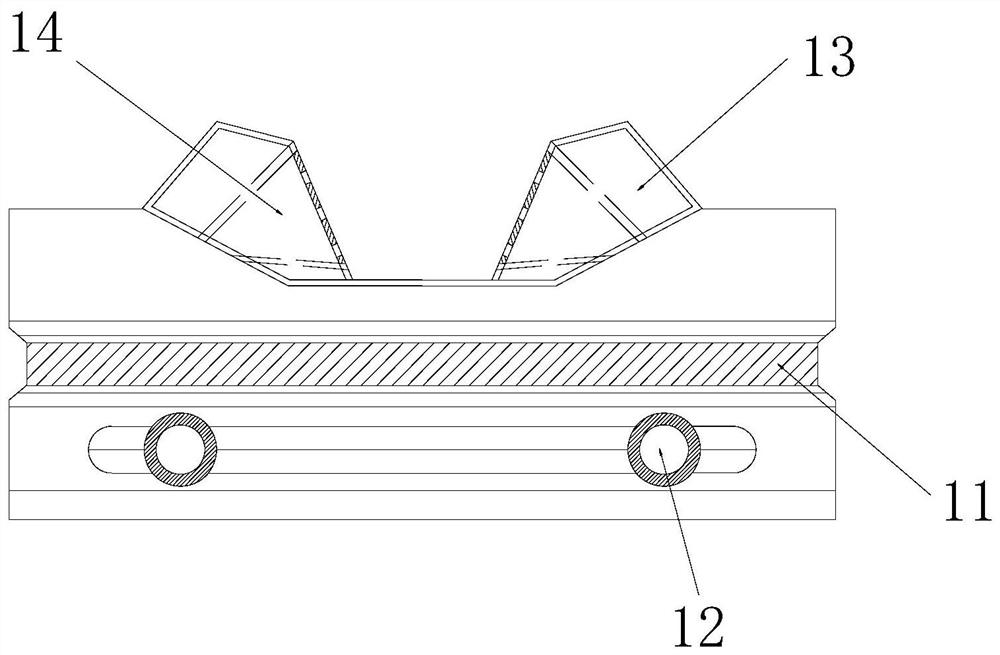

[0028] The present invention provides a knife punching device for a numerically controlled milling machine, the structure of which includes a fire plate 1, a clamper 2, a gas chamber 3, and a console 4. The fire plate 1 is inlaid directly below the clamper 2, The clamper 2 is located directly above the gas cabin 3, and the gas cabin 3 is embedded and installed under the right side of the console 4; The flame port 14, the adjustment mechanism 11 is inlaid directly above the heat dissipation port 12, the heat dissipation port 12 is symmetrically installed on the left and right sides of the lower end of the adjustment mechanism 11, and the fixed groove 13 is symmetrically embedded in the upper end of the fire tray 1 On the left and right sides, the flame port 14 is embedded in the inner end surface of the fixing groove 13 .

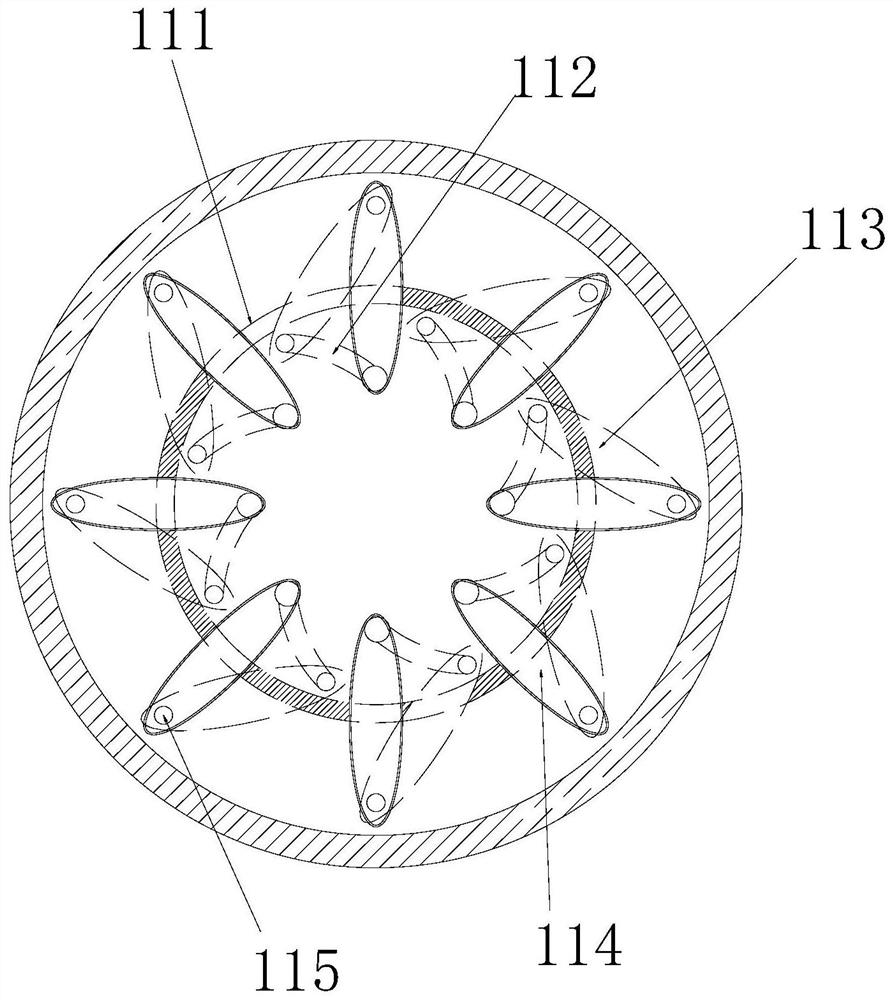

[0029] Wherein, the adjustment mechanism 11 includes a movable disk 111, a chute 112, an air-closin

Embodiment 2

[0034] as attached Figure 4 to attach Figure 8 As shown: the air-closing sheet 113 includes a connecting shaft 131, a folding layer 132, an air inlet 133, a sliding shaft 134, and a second flame outlet 135. The connecting shaft 131 is nested and connected to the movable shaft 115, and the folding layer 132 It is inlaid directly above the air inlet 133, the air inlet 133 is embedded and installed directly below the second flame outlet 135, the sliding shaft 134 is movably engaged with the inner end surface of the chute 112, and the second The flame outlet 135 is evenly inlaid on the inner surface of the upper end of the air-tight sheet 113. The folded layer 132 is made of multi-layer variable-direction interference plastic sheets, which can provide lateral movement capability when the air-tight sheet 113 swings, and ensure that the gas airtightness.

[0035]Wherein, the second flame outlet 135 includes an airtight ring 351, a cone-shaped valve 352, a second air inlet 353, and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap