Direct tensile strength test method of inorganic binding material stabilizing material

A technology of inorganic binder and testing method, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of deviation of design results, inability to directly use asphalt mixture and cement concrete, lack of other problems, and achieve weak deformation ability , Improve the mechanical performance test, the effect of high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

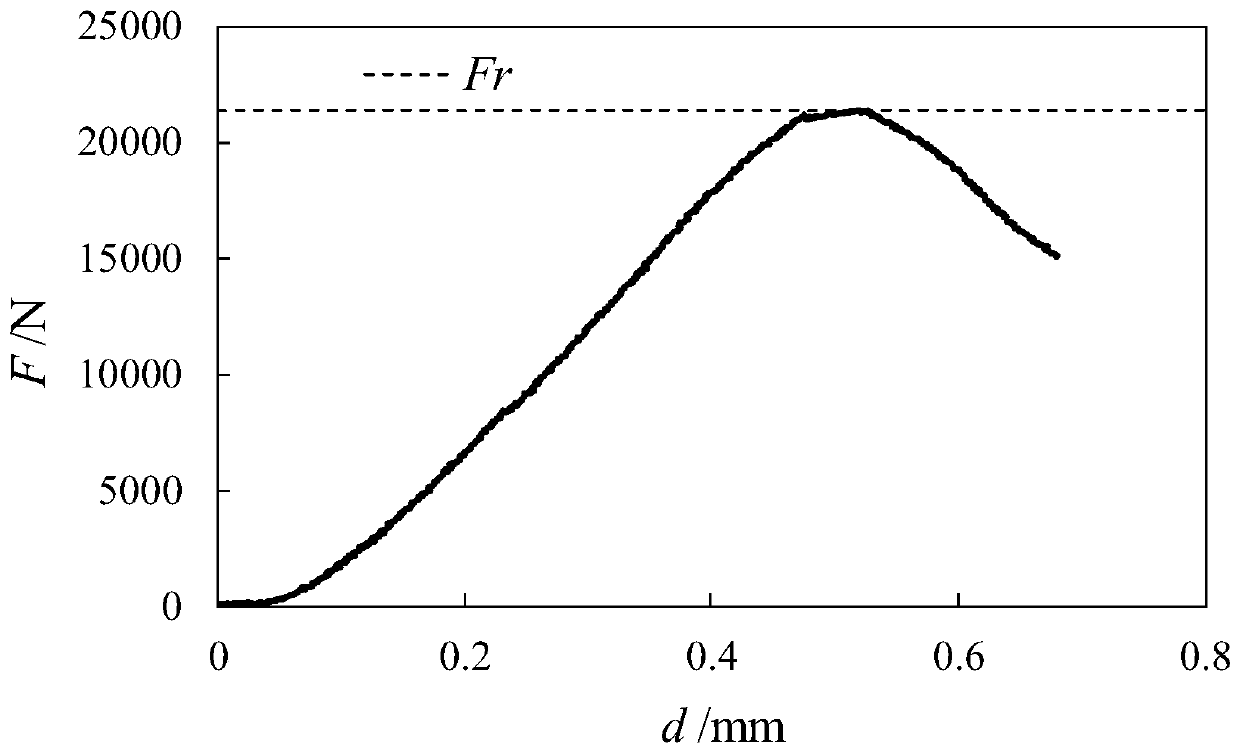

[0050] Taking cement-stabilized graded crushed stone as an example, the implementation of the direct tensile strength test method for inorganic binder-stabilized materials is described.

[0051] 1) Select the cement-stabilized graded crushed stone CBG25 graded in Table 1 to carry out heavy-duty compaction tests, and determine the optimum moisture content of 5.5% and cement dosage of 6%.

[0052] Table 1 Gradation composition of cement-stabilized graded crushed stone CBG25

[0053] Sieve hole(mm) 26.5 19 13.2 9.5 4.75 2.36 1.18 0.6 0.3 0.15 0.075 Passing rate(%) 99.9 83.4 68.1 57.9 40.2 24.9 16.6 10.7 6.9 5.5 4.1

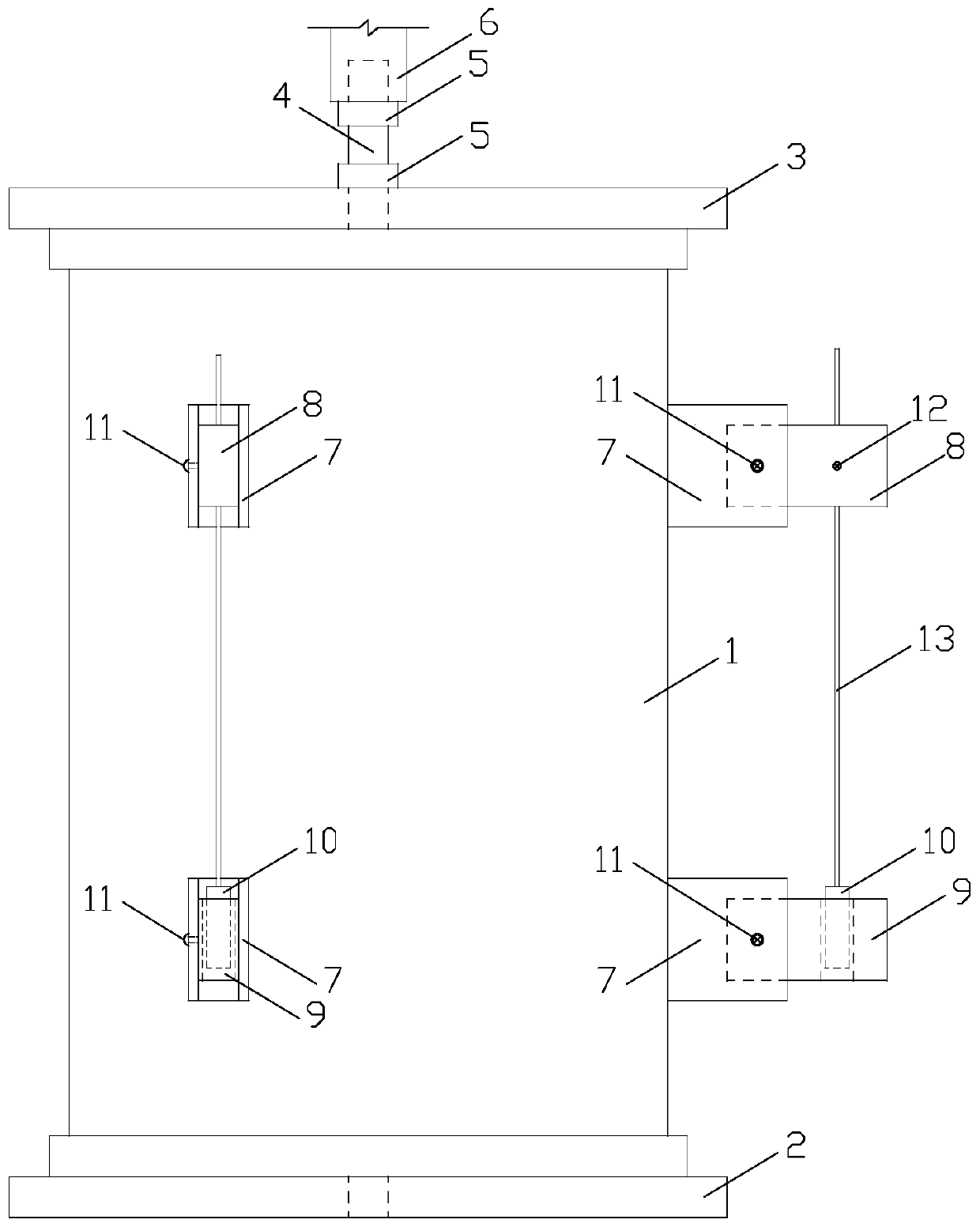

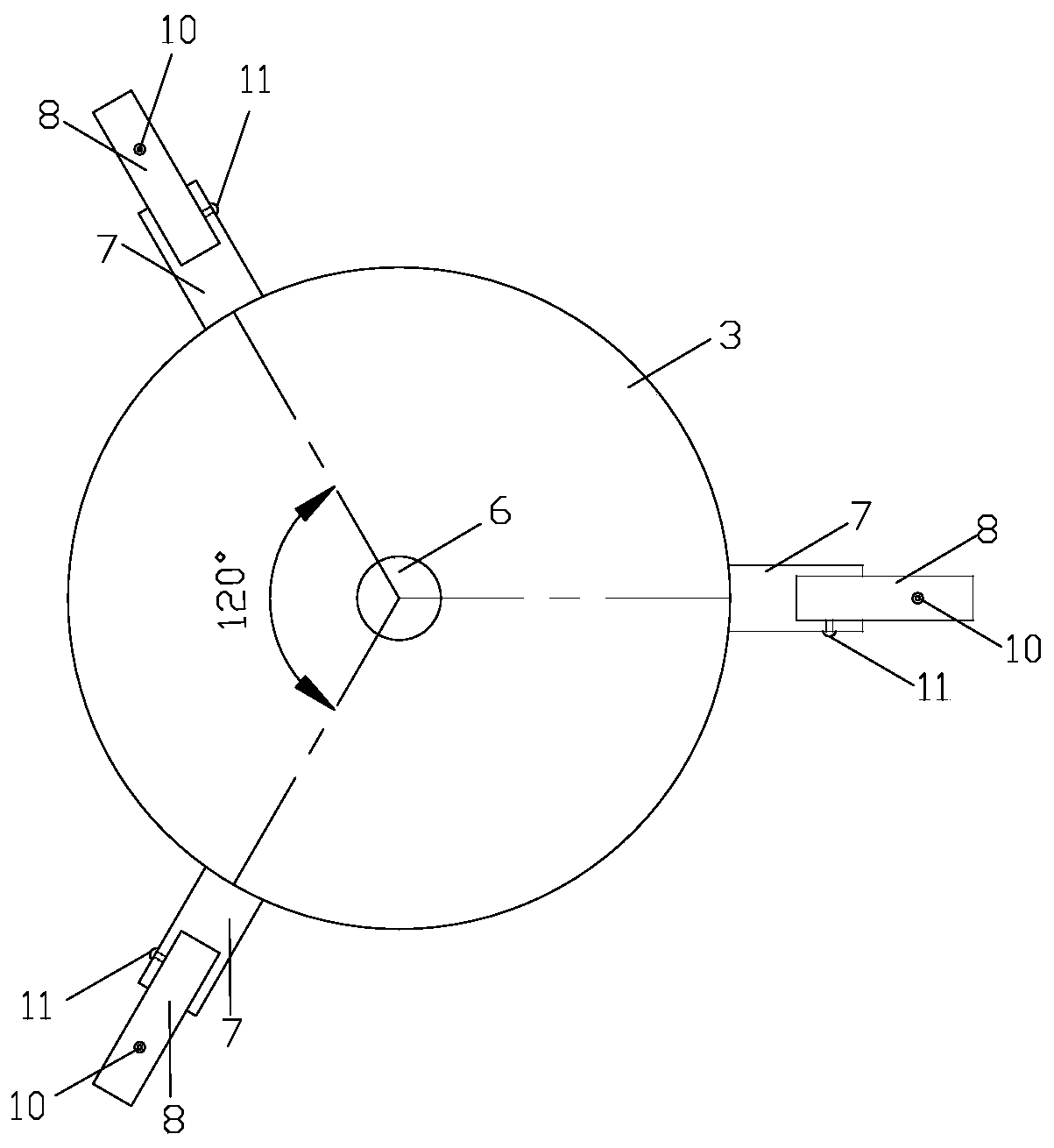

[0054]2) Since the CBG25 in step 1) is a coarse-grained material, according to the design result in step 1), 15 cylindrical specimens with a diameter×height of φ150mm×300mm were molded.

[0055] 3) Put the test pieces in step 2) in a standard health care room for health preservation, and the health preservation period is 90 days

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap