Tail gas treatment system in sulfuric acid preparation process

A preparation process and exhaust gas treatment technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of hidden dangers in safety and environmental protection, low driving rate and high cost, and achieve the promotion of reaction degree and reaction rate, and prevent air pollution. , the effect of promoting conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] Example 1

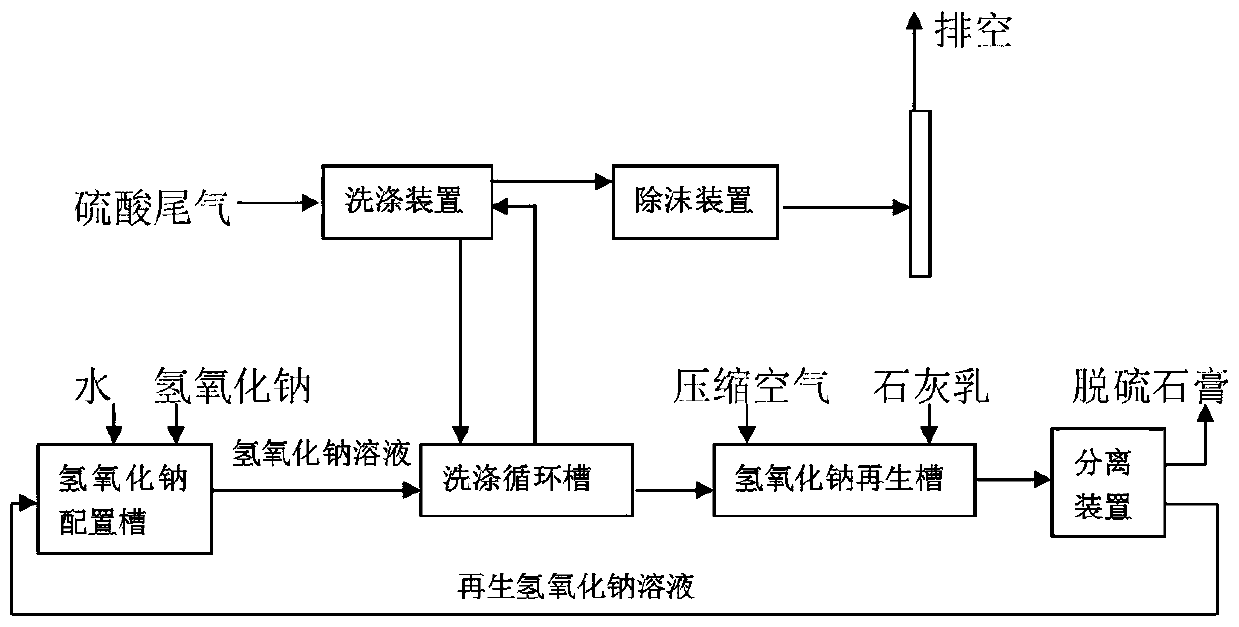

[0020] The sulfuric acid tail gas enters the double-spray washing pipe, sprays and washes with sodium hydroxide solution, and is emptied after being defoamed by the double-block demister.

[0021] Sodium hydroxide and water are configured into a 2-3% solution in the configuration tank and enter the washing circulation tank. The circulating liquid is pumped to the re-spray washing pipe for circular washing. The pH value of the circulation tank is controlled to be 8-10, and the slurry in the circulation tank is Transfer to the sodium hydroxide regeneration tank one after another, add lime milk and compressed air for regeneration, the recycled slurry after the reaction is separated, the desulfurized gypsum is taken out, and the regenerated sodium hydroxide solution is returned to the configuration tank.

Example Embodiment

[0022] Example 2

[0023] The flue gas produced by a company in Lufeng County, Chuxiong Prefecture, Yunnan Province:

[0024] 1. SO 2 Fan flow rate 2150m 3 ∕min, tail gas SO 2 Concentration: 300ppm, exhaust SO 2 Concentration: about 110mg / Nm 3 , absorbed SO 2 Content: 260ppm. The vapor density of sulfur dioxide is 2.26.

[0025] 2. According to the sulfur dioxide fan flow rate and SO 2 The concentration is calculated as SO per hour 2 Yes: 2150*260*60*2.26*10 -6 =75.8 kg.

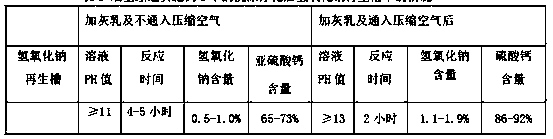

[0026] Above-mentioned flue dust is through the situation in the sodium hydroxide regeneration tank after washing and purifying in embodiment 1 as shown in table 1 below:

[0027] Table 1 Situation in the sodium hydroxide regeneration tank after the dust is washed and purified in Example 1

[0028]

[0029] It can be seen from the above table data that adding compressed air while adding milk of lime into the sodium hydroxide regeneration tank can promote the conversion of calcium sulfite to cal

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap