Fermentation medium and fermentation technology

A fermentation medium, fermentation culture technology, applied in fermentation, microorganism-based methods, microorganisms, etc., can solve the problem of less research on fermentation regulation, and achieve the effect of maintaining secondary metabolic activity, prolonging fermentation cycle, and improving biosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

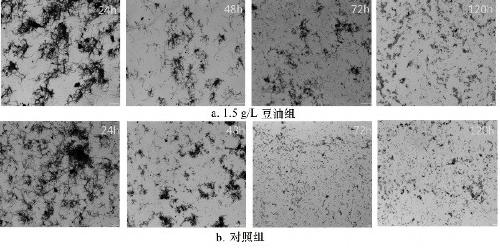

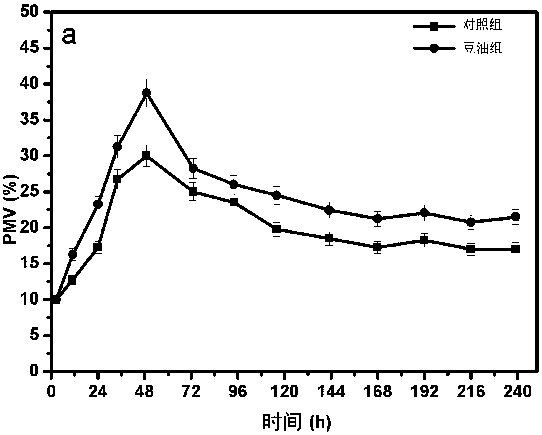

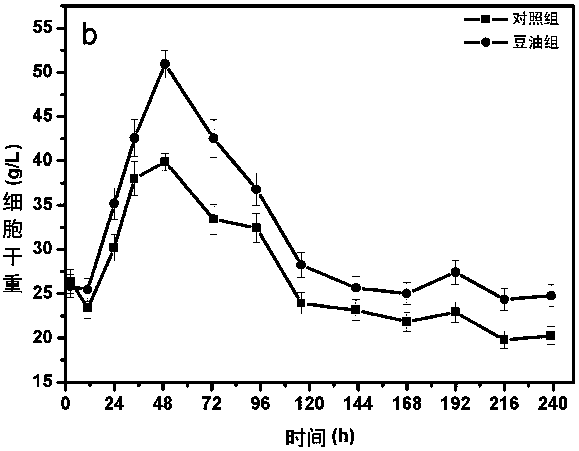

Image

Examples

Embodiment 1

[0040] A kind of fermentation medium, is used for fermenting nimoctine, comprises soybean oil in the described medium, and the pH value of described fermentation medium is 7.5;

[0041] Include carbon source, nitrogen source, auxiliary agent, defoamer in the described fermentation medium; Wherein, described carbon source comprises soybean oil, glucose, maltodextrin; Described nitrogen source comprises soybean meal, corn steep liquor; Said auxiliary Agents include magnesium sulfate, copper sulfate, cobalt chloride, zinc sulfate, manganese sulfate, sodium molybdate, calcium carbonate;

[0042] The fermentation medium includes ingredients in terms of concentration: soybean oil 5.0g / L, glucose 15g / L, maltodextrin 95g / L, soybean cake powder 20g / L, corn steep liquor 9g / L, magnesium sulfate 0.8g / L, sulfuric acid Copper 0.011g / L, cobalt chloride 0.001g / L, zinc sulfate 0.002g / L, manganese sulfate 0.001g / L, sodium molybdate 0.003g / L, calcium carbonate 5g / L; Fractio

Embodiment 2

[0049] A kind of fermentation medium, is used for nimoctine fermentation, comprises soybean oil in the described medium, and the pH value of described fermentation medium is 7.0;

[0050] Include carbon source, nitrogen source, auxiliary agent, defoamer in the described fermentation medium; Wherein, described carbon source comprises soybean oil, glucose, maltodextrin; Described nitrogen source comprises soybean meal, corn steep liquor; Said auxiliary Agents include magnesium sulfate, copper sulfate, cobalt chloride, zinc sulfate, manganese sulfate, sodium molybdate, calcium carbonate;

[0051] The fermentation medium includes components in terms of concentration: soybean oil 0.25g / L, glucose 25g / L, maltodextrin 75g / L, soybean cake powder 30g / L, corn steep liquor 7g / L, magnesium sulfate 1.2g / L, sulfuric acid Copper 0.009g / L, cobalt chloride 0.003g / L, zinc sulfate 0.001g / L, manganese sulfate 0.002g / L, sodium molybdate 0.001g / L, calcium carbonate 7g / L; Fract

Embodiment 3

[0058] A kind of fermentation medium, is used for fermenting nimoctine, comprises soybean oil in the described medium, and the pH value of described fermentation medium is 7.4;

[0059] Include carbon source, nitrogen source, auxiliary agent, defoamer in the described fermentation medium; Wherein, described carbon source comprises soybean oil, glucose, maltodextrin; Described nitrogen source comprises soybean meal, corn steep liquor; Said auxiliary Agents include magnesium sulfate, copper sulfate, cobalt chloride, zinc sulfate, manganese sulfate, sodium molybdate, calcium carbonate;

[0060] The fermentation medium includes ingredients by concentration: soybean oil 2.5g / L, glucose 18g / L, maltodextrin 90g / L, soybean cake powder 22g / L, corn steep liquor 9g / L, magnesium sulfate 0.9g / L, sulfuric acid Copper 0.01g / L, cobalt chloride 0.002g / L, zinc sulfate 0.002g / L, manganese sulfate 0.001g / L, sodium molybdate 0.003g / L, calcium carbonate 5g / L; Fraction of 0.9%

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap