Nano-catalyst for high-efficiency gasoline pyrolysis

A nano-catalyst and pyrolysis gasoline technology, applied in the field of nano-catalysts, can solve the problems of short timeliness, high cost, ineffective PM particles, etc., and achieve the effects of increased range, improved light-off and durability, and increased disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0018] Example 1:

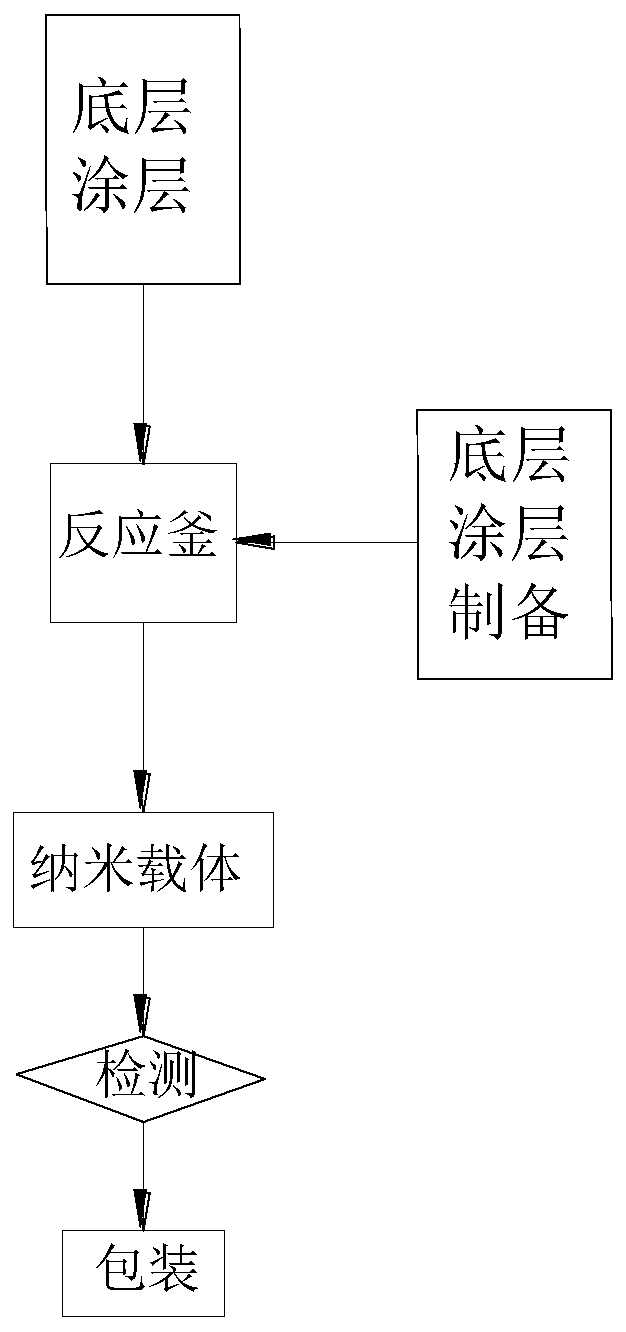

[0019] see figure 1 , a nano-catalyst for high-efficiency pyrolysis gasoline, comprising a catalyst with nano-bluestone honeycomb ceramics as a carrier, the surface of the catalyst carrier is coated with a bottom coating and an outer coating, and the bottom coating comprises a diisocyanate prepolymer, an active double bond containing Monohydroxy compound, oxidizing agent and polymerization inhibitor, outer coating contains Al 2 O 3 -TiO 2 Composite oxide, active metal oxide NiO and Pd / Ce-Zr solid solution powder;

[0020] According to the weight ratio of the catalyst, the fraction of the diisocyanate prepolymer in the primer coating is 4 to 10 parts, the fraction of the active double bond-containing monohydroxy compound is 2 to 4 parts, and the fraction of the oxidant is 4 to 6 parts and the parts of polymerization inhibitor are 2 to 6 parts;

[0021] According to the weight ratio of the catalyst, the Al in the outer coating 2 O 3 -TiO 2 The number o

Example Embodiment

[0025] Embodiment 2:

[0026] According to the weight ratio of the catalyst, the fraction of the diisocyanate prepolymer in the primer coating is 6 to 8 parts, the fraction of the active double bond-containing monohydroxy compound is 2 parts, and the fraction of the oxidant is 4 parts and the proportion of polymerization inhibitor is 3 to 5 parts;

[0027] According to the weight ratio of the catalyst, the Al in the outer coating 2 O 3 -TiO 2 The number of parts of the composite oxide is 8 parts, the number of parts of the active metal oxide NiO is 4-6 parts, and the number of parts of the Pd / Ce-Zr solid solution powder is 3-4 parts.

[0028] Take 6~8 parts of diisocyanate prepolymer and add it into the reaction kettle, 2 parts of active double bond-containing monohydroxy compound are at least one of silicone or silicone fluorine-modified allyl ether and added simultaneously according to the formula 4 parts of oxidant and 3 to 5 parts of polymerization inhibitor, the stirre

Example Embodiment

[0030] Embodiment three:

[0031] According to the weight ratio of the catalyst, the fraction of the diisocyanate prepolymer in the bottom coating is 7 parts, the fraction of the active double bond monohydroxy compound is 3 parts, the fraction of the oxidant is 5 parts and the resistance The number of parts of the polymerization agent is 4 parts;

[0032] According to the weight ratio of the catalyst, the Al in the outer coating 2 O 3 -TiO 2 The number of parts of the composite oxide is 9 parts, the number of parts of the active metal oxide NiO is 5 parts and the number of parts of the Pd / Ce-Zr solid solution powder is 3 parts.

[0033] Take 7 parts of diisocyanate prepolymer and add it into the reactor, 3 parts of active double bond-containing monohydroxy compound are at least one of organosilicon or organosilicon fluorine-modified allyl ether and add 5 parts simultaneously according to the formula oxidant and 4 parts of polymerization inhibitor, the stirrer in the reaction

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap