Feeding device

A feeding device and weighing technology, applied in the directions of measuring device, loading/unloading, transportation and packaging, can solve problems such as affecting the quality of finished products, inability to effectively control the rhythm of feeding, and unstable processing in subsequent processes, etc. Achieve stable and reliable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

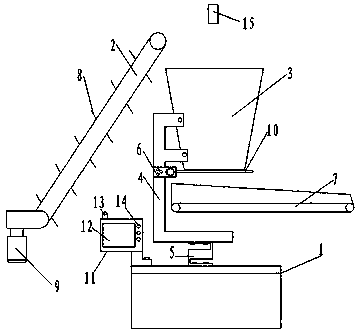

[0023] see figure 1 , The embodiment of the present invention includes: a feeding device, including: a platform 1, a feeding device 2, a weighing trough 3, a bracket 4, a load cell 5, a feeding device 6, a feeding conveyor belt 7 and a control cabinet 11.

[0024] Further explain the working principle of the feeding device: the staff turns on the power supply of the feeding device through the control button 14 on the control cabinet 11, and sets and debugs the weight range and weighing tank 3 of the material to be weighed on the HMI touch screen 12 The 2-level capacity height, the 2-level capacity height value refers to the capacity height at which

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap