Full automatic leavening tower

A fully automatic, proofing technology, applied in the fields of dough fermenter, baking, food science, etc., can solve the problems of unavoidable contact between human hands and food, reduce food hygiene and safety, reduce food production efficiency, etc., and save labor costs. , The effect of improving health and safety and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

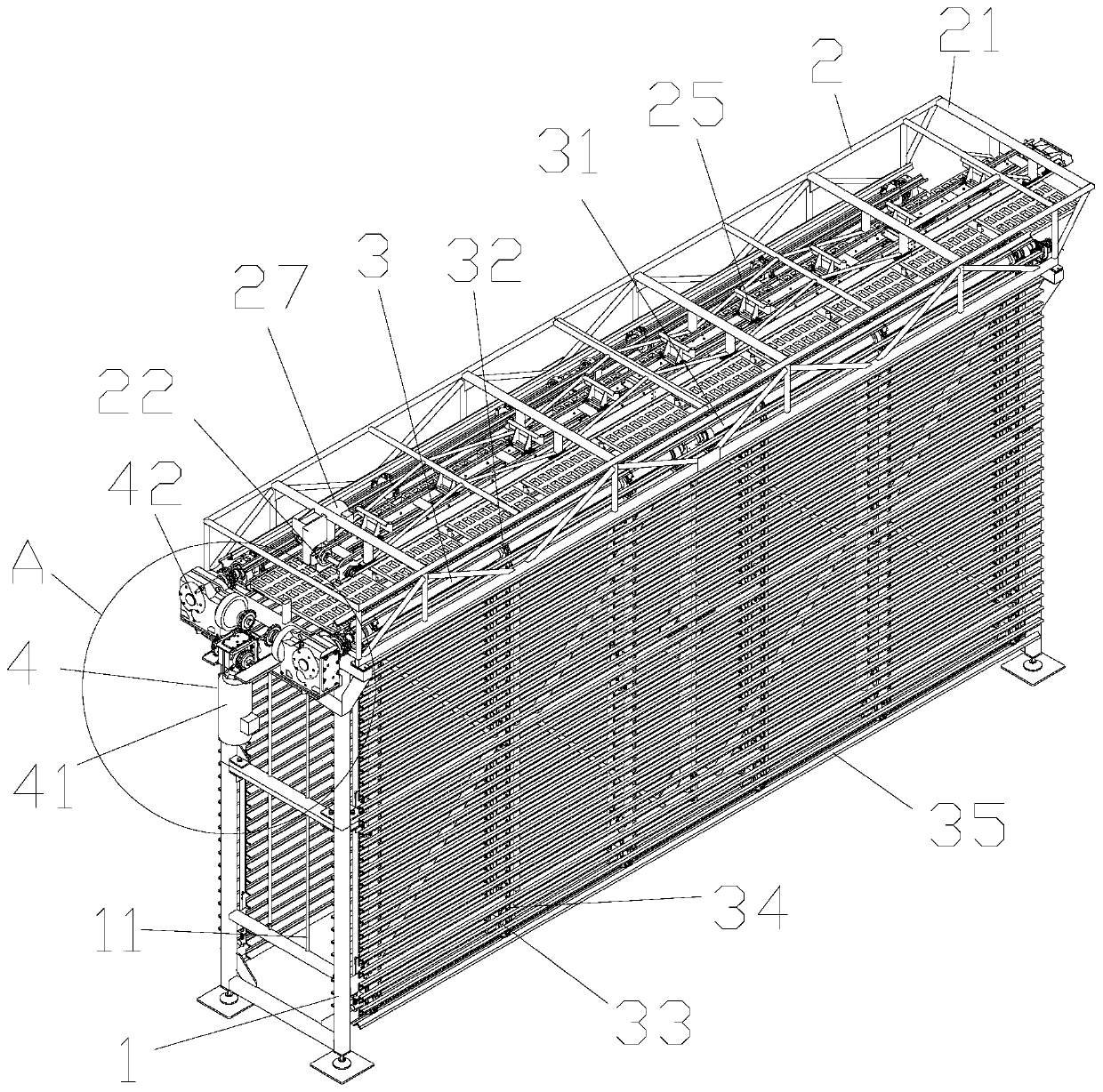

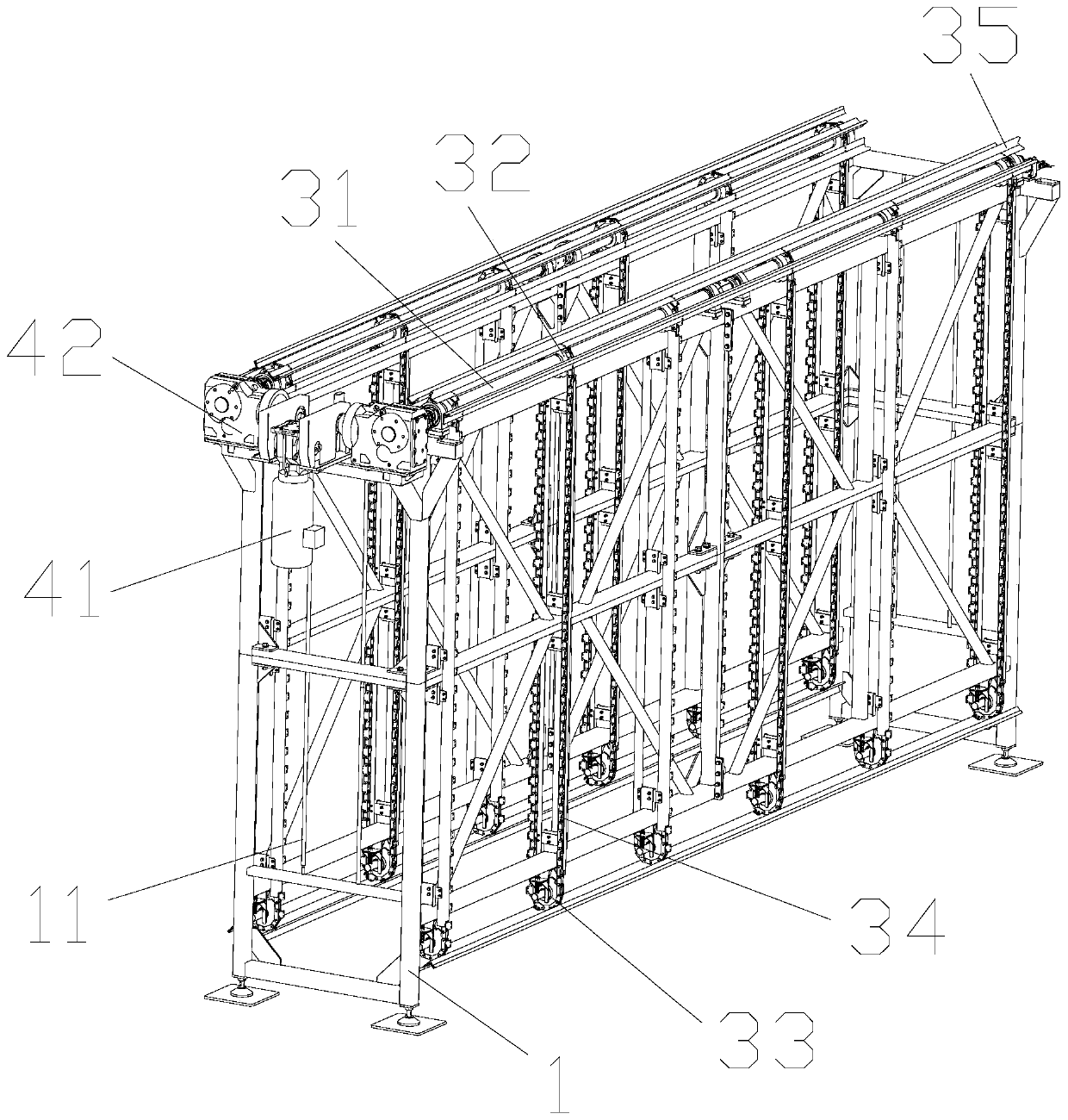

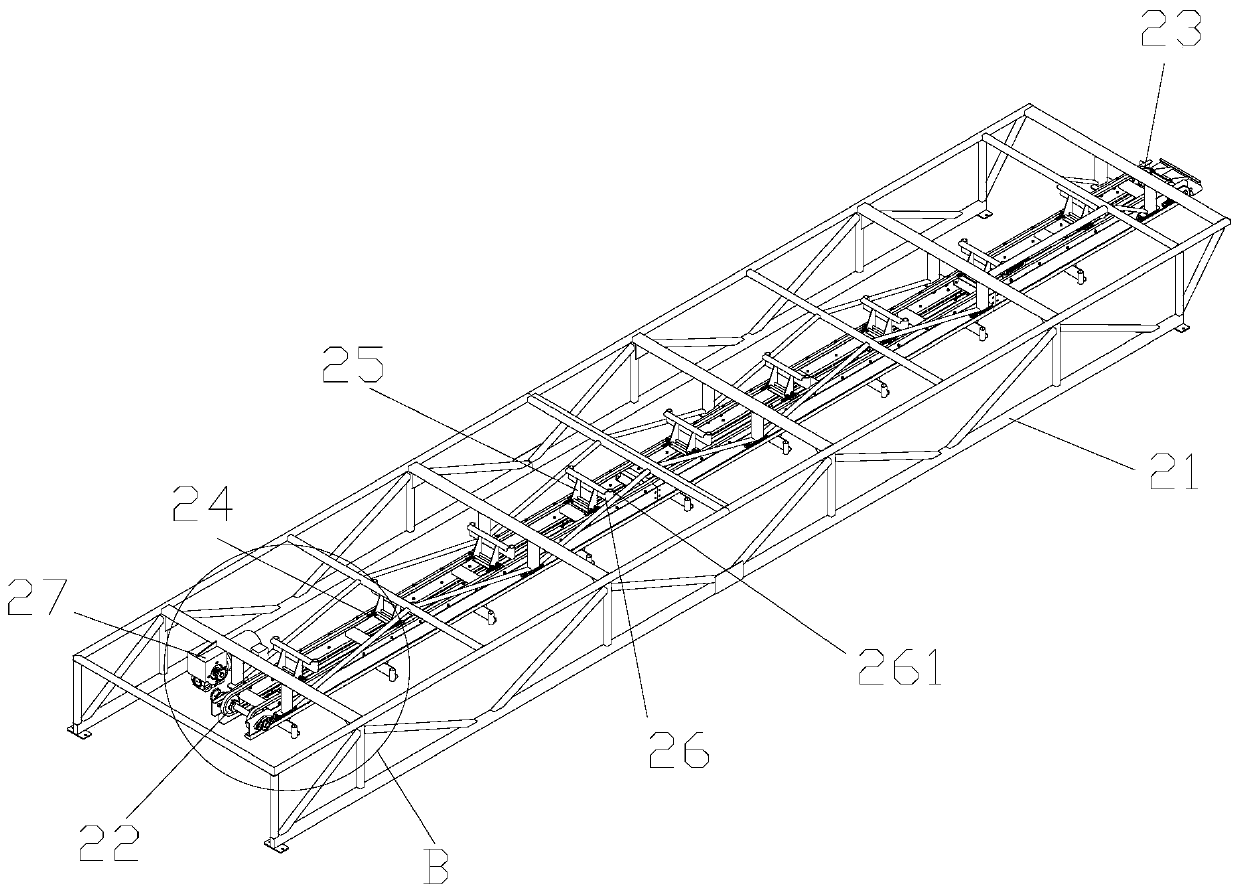

[0028] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the structure of the fully automatic proofing tower, figure 2 It is another schematic diagram of the structure of the fully automatic proofing tower (the tower slices of the pushing device and the side parts are not shown). A fully automatic proofing tower, comprising a frame 1, a pushing device 2 installed on the frame 1 for pushing the baking pan, a descending device 3 for driving the roasting pan to move downward, and a driving assembly for driving the descending device 3 to work 4. The baking tray with food transported to the entrance of the proofing tower is pushed into the proofing tower by the pushing device 2, and the baking tray with food is transported from the top of the frame 1 to the bottom of the frame 1 by the descending device 3, and finally the baking tray with the food will be

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap