Battery string welding mechanism

A welding mechanism and battery technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high unqualified rate, waste of manpower, unfavorable product promotion, etc., and achieve high welding qualified rate, reasonable structural design, effective The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

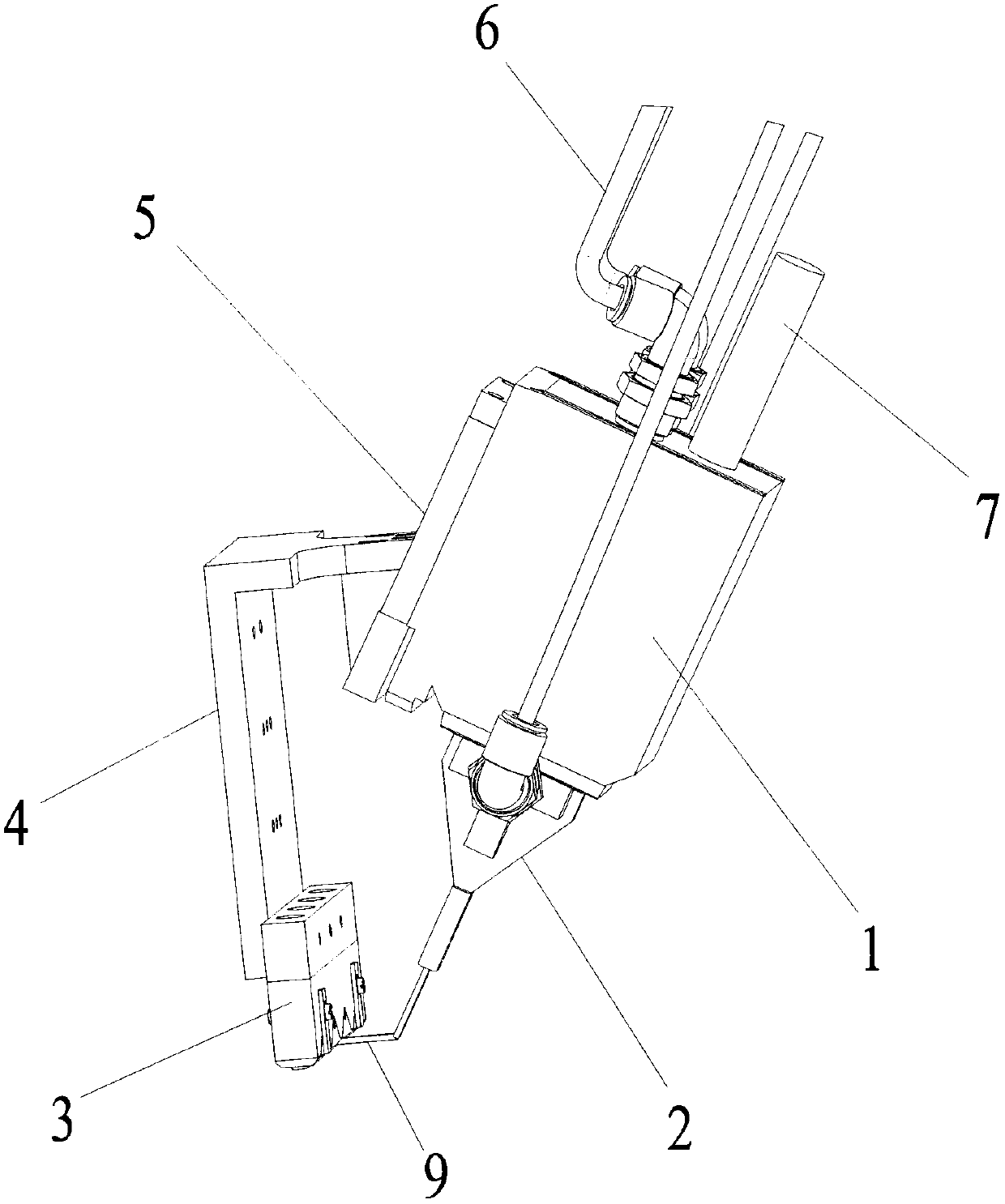

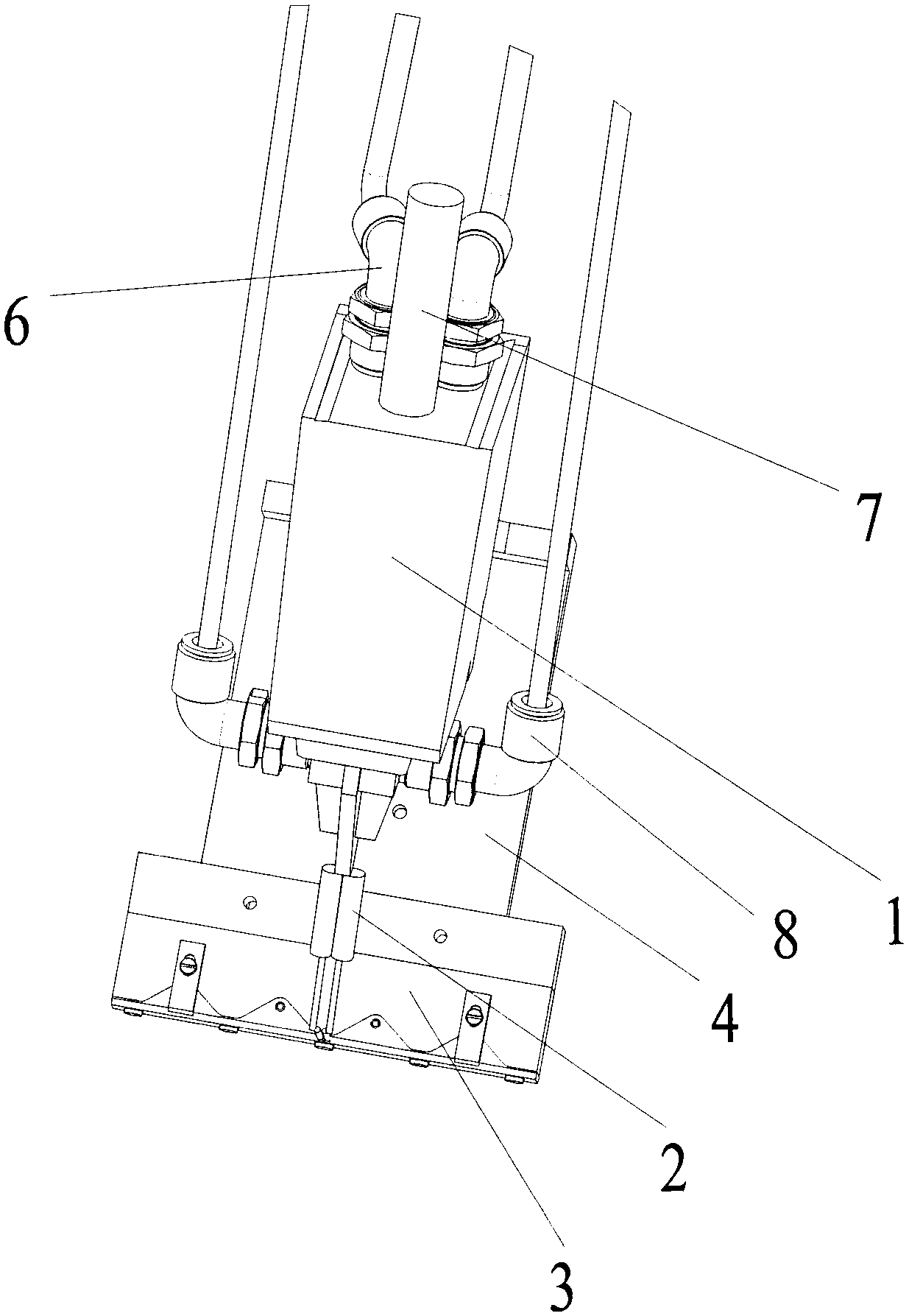

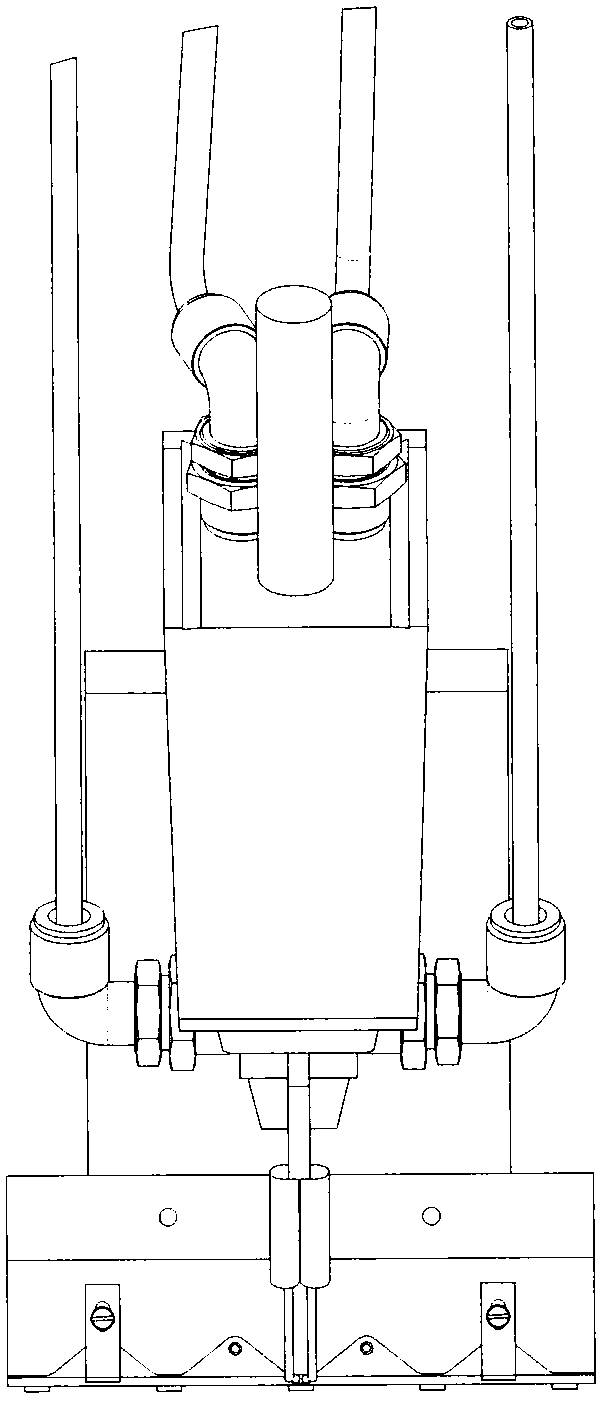

[0030] The specific structure is as Figure 1-3 As shown, the battery string welding mechanism includes an induction head 1, an induction rod 2, a welding head 3, a lifting frame 4, an induction head fixing seat 5, a circulating water pipe joint 6, and a power cord 7. The lower end of the induction head 1 passes The upper end of the induction rod 2 is screwed, and the lower end of the induction rod 2 is connected to the wire 9 of the welding head 3. The upper end of the induction head 1 is hermetically connected to two circulating water pipe joints 6, and the two circulating water pipe joints 6 are used to connect the circulating water pipe. The head 1 provides circulating water to cool and control the temperature of the induction head 1 and the welding head 3 at the lower end; the ind

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap