Preparation method of positive electrode material for high-power lithium ion battery

A technology for lithium-ion batteries and positive electrode materials, which is applied in the field of preparation of positive electrode materials for lithium-ion batteries, can solve the problems of increased contact area between materials and electrolytes, low tap density and compaction density, and poor crystallinity of precursors. Achieve excellent cycle performance, good consistency, loose and porous surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0041] Example 1:

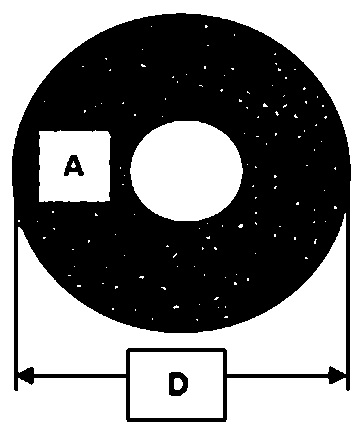

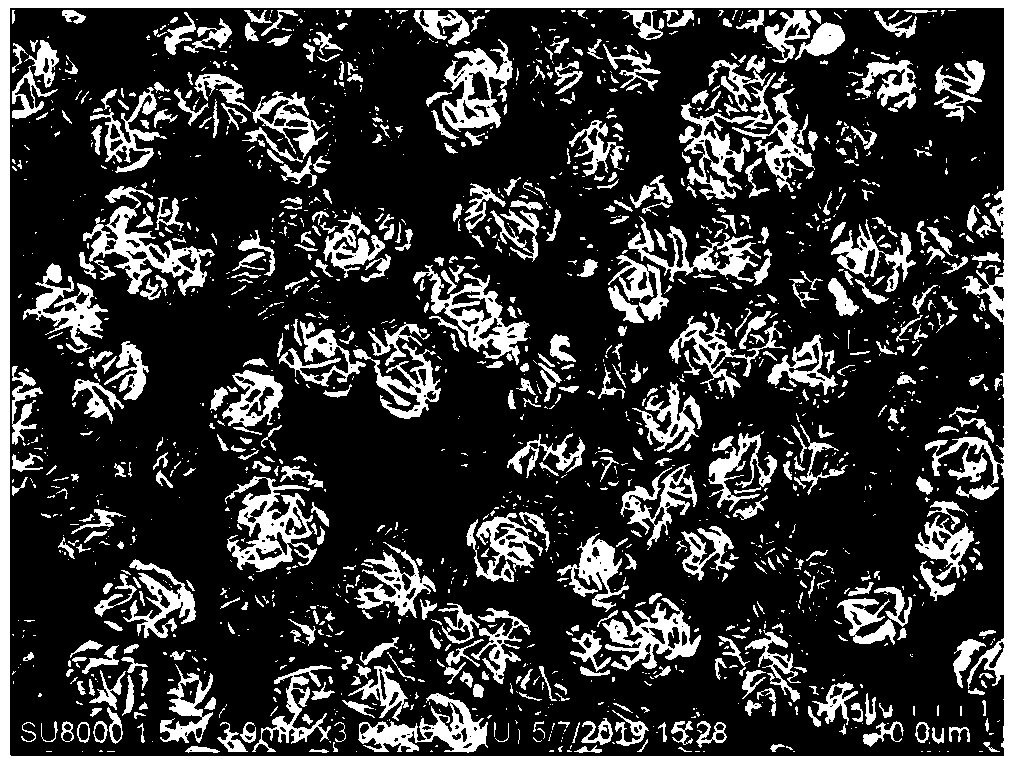

[0042] A positive electrode material for a lithium ion battery of the present invention, the chemical formula of the positive electrode material is Li 1.2 Ni 0.6 Co 0.2 Mn 0.2 O 2 ,like figure 1 As shown, the positive electrode material is a secondary particle with a hollow microsphere structure, and the outer shell of the secondary particle is formed by aggregating several primary particles.

[0043] The preparation method of the positive electrode material comprises the following steps:

[0044] (1) Synthesis of Ni by co-precipitation method 0.6 Co 0.2 Mn 0.2 (OH) 2 Precursor, the synthesis of the precursor includes nucleation and inner core growth stage and shell growth stage, the specific operation includes: first, using sulfate containing nickel, cobalt and manganese to prepare a mixed metal salt solution with a total metal ion concentration of 2mol / L , the molar ratio of nickel-cobalt-manganese is 6:2:2, the sodium hydroxide solution that the

Example Embodiment

[0048] Example 2:

[0049] A positive electrode material for a lithium ion battery of the present invention, the chemical formula of the positive electrode material is Li 1.08 Ni 0.9 Co 0.08 Al 0.02 O 2 ,like figure 1 As shown, the positive electrode material is a secondary particle with a hollow microsphere structure, and the outer shell of the secondary particle is formed by aggregating several primary particles.

[0050] The preparation method of the positive electrode material comprises the following steps:

[0051] (1) Synthesis of Ni by co-precipitation method 0.9 Co 0.08 Al 0.02 (OH) 2Precursor, the synthesis of the precursor includes nucleation and inner core growth stage and shell growth stage, the specific operation includes: first, using sulfate containing nickel and cobalt to prepare a mixed metal salt solution with a total metal ion concentration of 2mol / L, nickel The molar ratio of cobalt is 90:8, and the aluminum molar concentration is 0.1mol / L metaal

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap