Large storage tank cylinder wall arc-shaped plate support

A large storage tank and arc-shaped plate technology, applied in the field of large storage tanks, can solve problems such as difficulty in ensuring process quality, lack of horizontal transportation, and low degree of mechanization, and achieve the effects of ensuring integrity, improving accident safety, and smooth transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

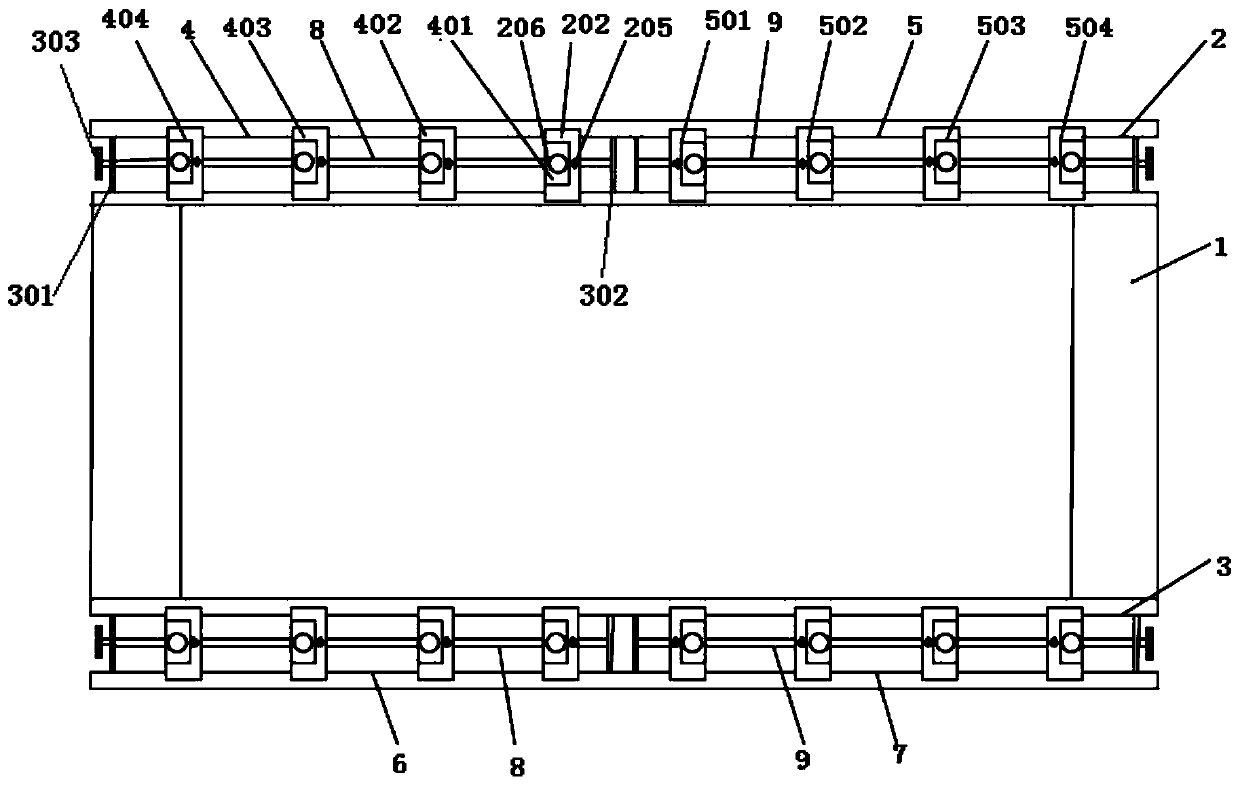

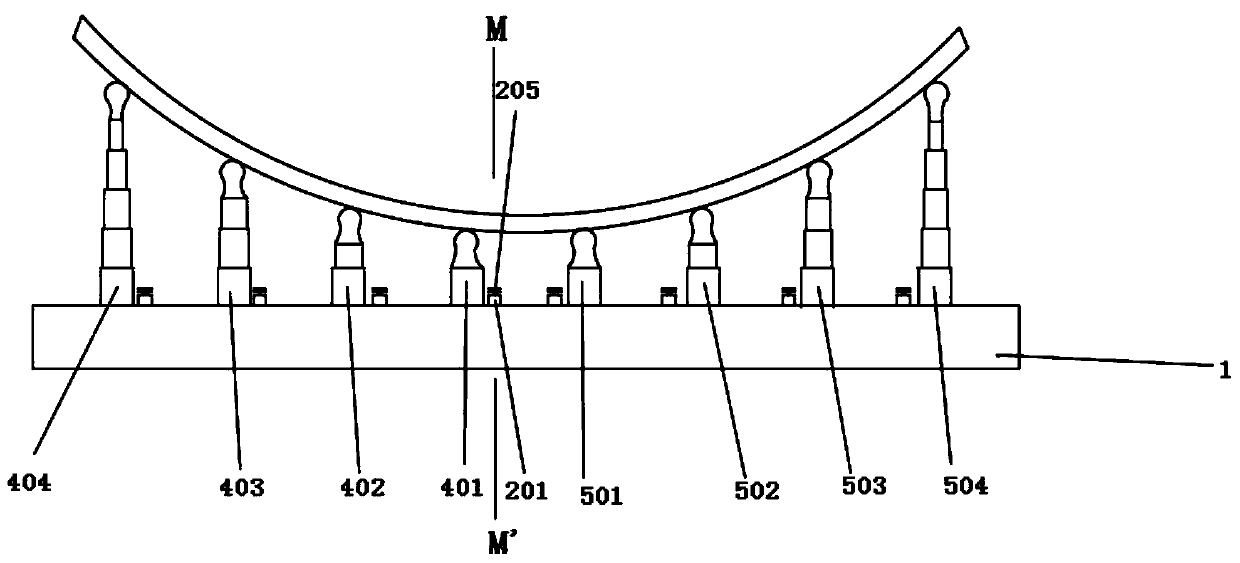

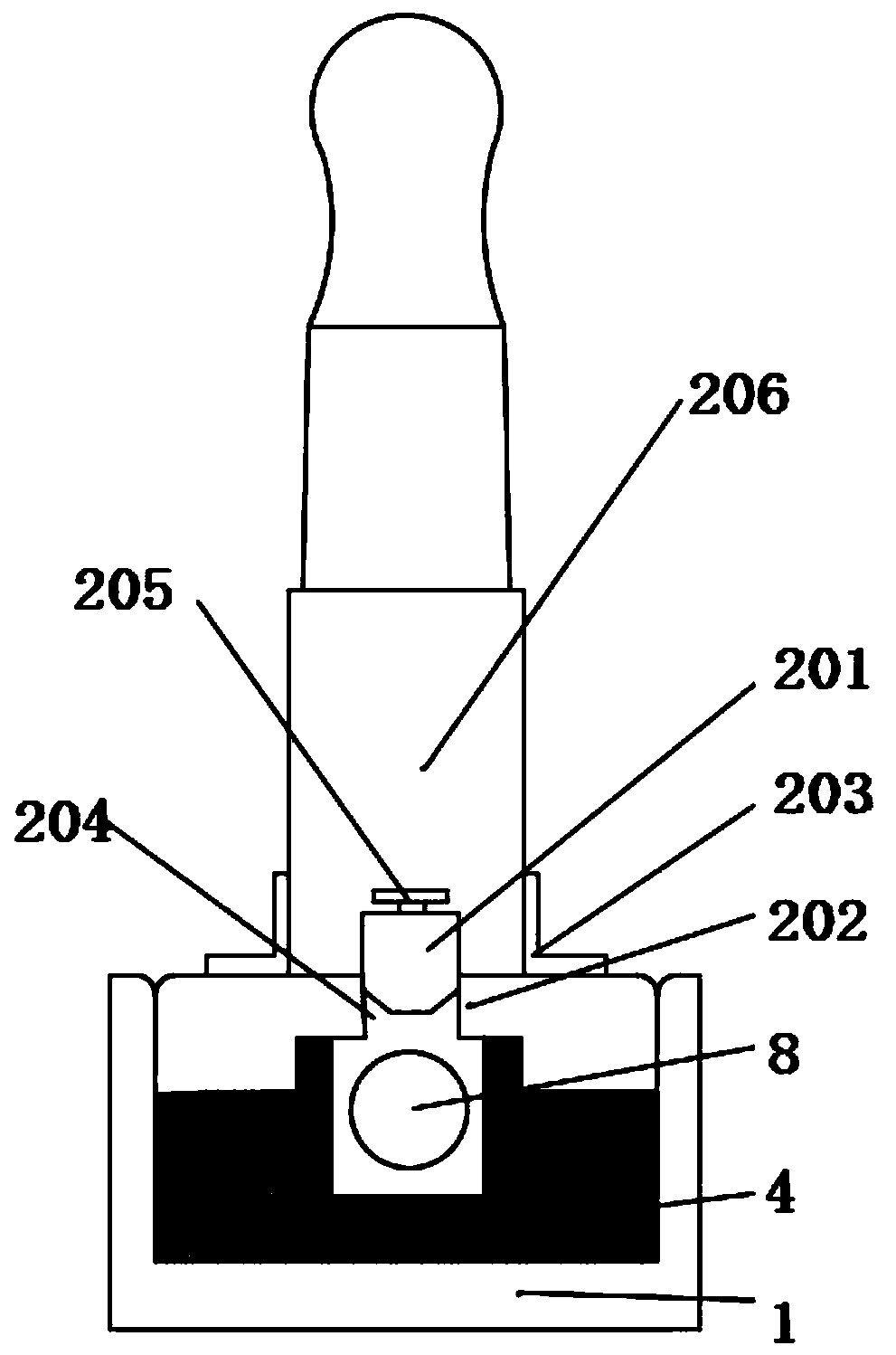

[0028] like Figure 1 to Figure 3 As shown, the bracket body 1 is a rectangular frame surrounded by four 160*160*10mm square steels, and the material of the square steels is Q235A. For the strength and stability of the bracket body 1 , two square steel beams can be installed at the bottom of the bracket body 1 by welding.

[0029] A first groove 2 is opened on one side of the bracket body 1, and a first linear guide 4 and a second linear guide 5 are fixed in the first groove 2. The first linear guide 4 and the second linear guide 5 and the movable support brackets arranged above it are symmetrically arranged on the left and right sides, a second groove 3 is opened on the other side of the bracket body 1 opposite to the first groove 2, and a third straight line is fixed in the second groove 3 The guide rail 6 and the fourth linear guide 7, the third linear guide 6 and the fourth linear guide 7 and the movable support brackets arranged above them are symmetrically arranged, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap