Accurate fire extinguishing system for large oil filling equipment used in substation

A technology of oil-filled equipment and fire extinguishing system, which is applied in fire rescue and other fields, and can solve problems such as resource waste, untimely fire extinguishing, and easy delays in fire extinguishing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

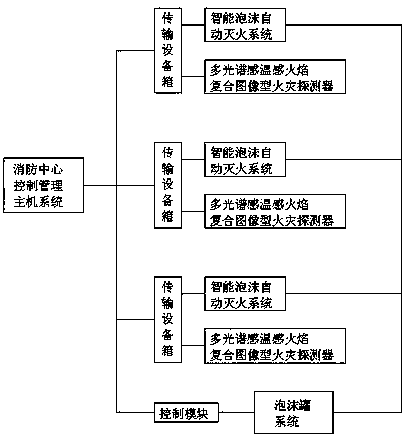

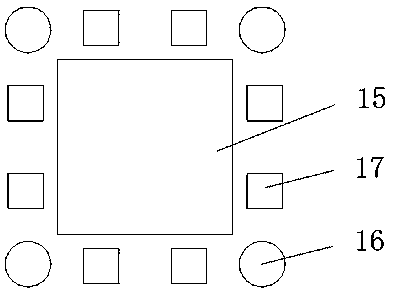

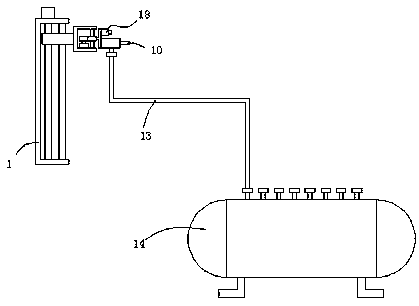

[0024] refer to Figure 1-4 , a precision fire extinguishing system for large oil-filled equipment used in substations, including a fire control center control management system and a transformer 15, the fire control center control management system is connected to a control module and a plurality of transmission equipment boxes, and the transmission equipment box is connected to an intelligent foam automatic fire extinguishing system 17 The multi-spectral temperature-sensing flame composite image fire detector 16, the intelligent foam automatic fire extinguishing system 17 is connected with the foam tank system 14, the intelligent foam automatic fire extinguishing syste

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap